Anti-code-spraying anti-blooming plastic packaging bottle and processing technology thereof

A processing technology and packaging bottle technology, which can be applied to other household appliances, household components, household appliances, etc., can solve the problems of unclear spraying and smearing of the bottom of plastic packaging bottles, and achieve the solution of spraying smearing and flat bottom of the bottle , good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042]A kind of anti-spray code blooming plastic packaging bottle, its volume is 500mL, and it is processed by following process:

[0043] Ingredients: Take 1000g of high-density polyethylene, 20g of color masterbatch, mix well;

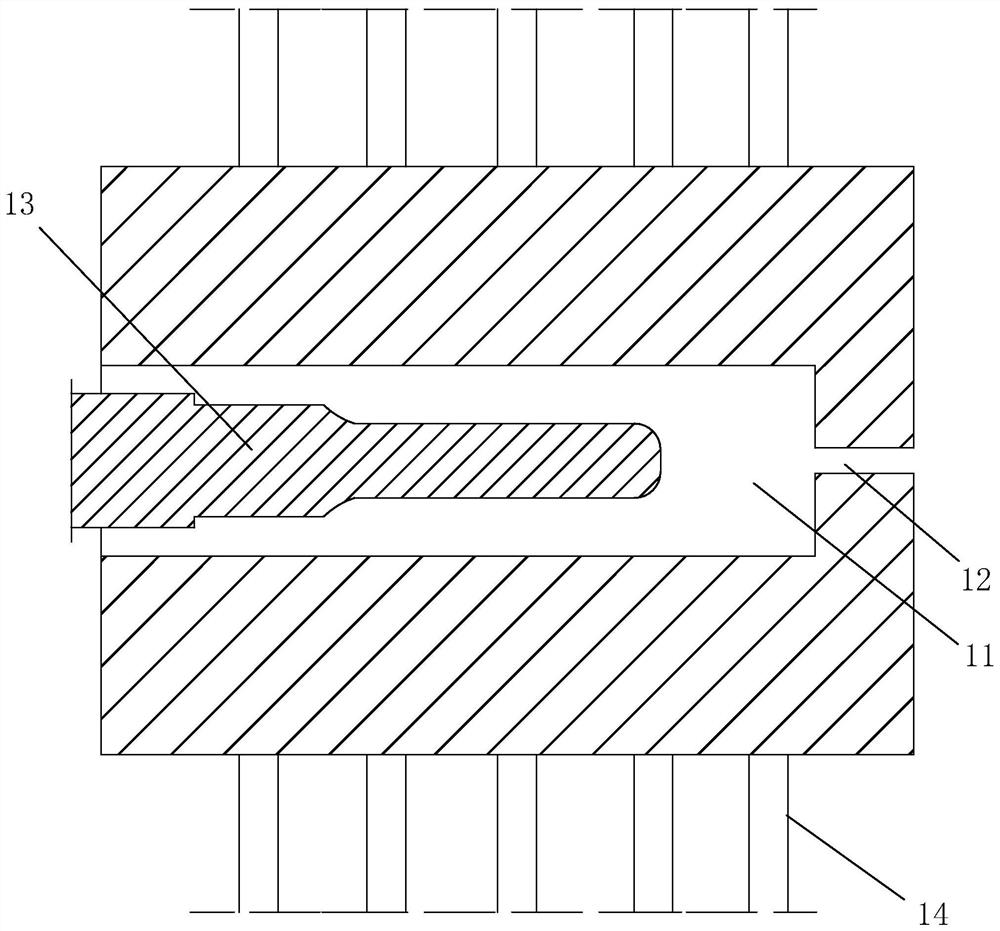

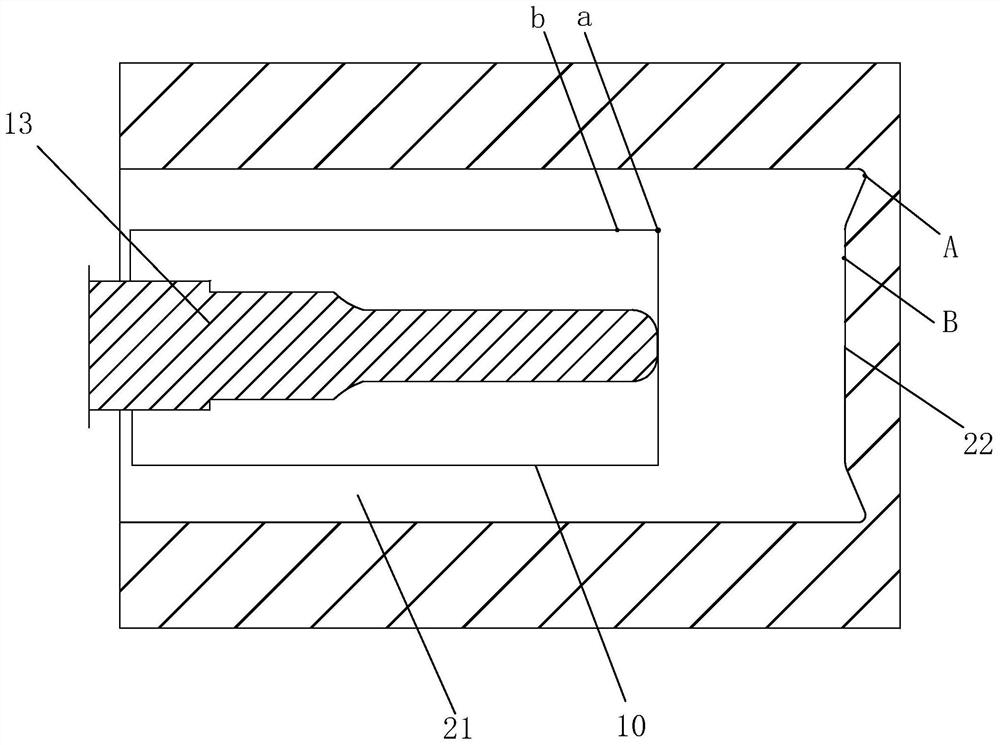

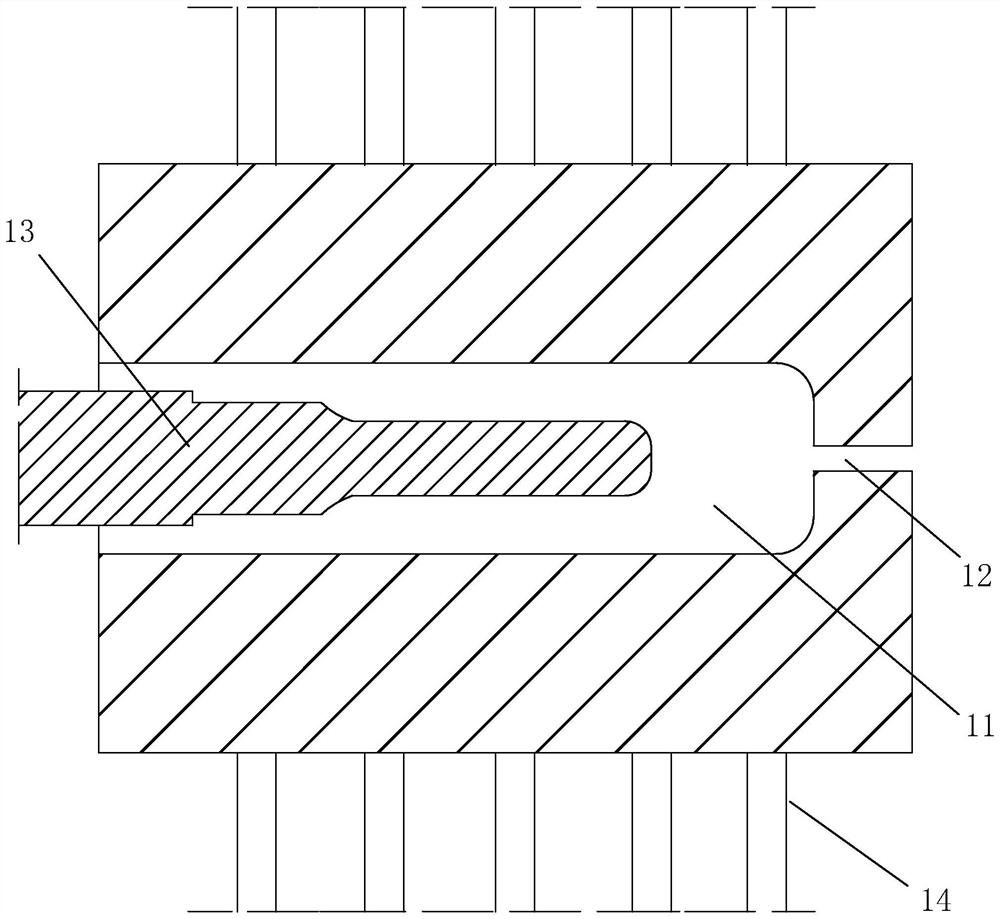

[0044] Injection molding: put the above mixture into the barrel of the injection molding machine, the temperature in the front area of the barrel is 190°C, and the feeding temperature is 230°C; figure 1 For the corresponding injection mold, the temperature of each mold area is as follows: the oil temperature in the bottle bottom mold area is 140°C, and an oil pipe is installed; the oil temperature in the bottle shoulder mold area is 90°C, and an oil pipe is installed; the bottle body mold area is equipped with a There are many oil pipes, and the oil temperature of the oil pipe at the bottom, that is, near the bottom of the bottle, is 80°C, and the oil temperature of the rest of the oil pipes is 140°C; Die in and upper die out;

[0045] Blow moldi...

Embodiment 2

[0048] A kind of anti-spray code blooming plastic packaging bottle, its volume is 500mL, and it is processed by following process:

[0049] Ingredients: Take 1000g of high-density polyethylene, 20g of color masterbatch, mix well;

[0050] Injection molding: Add the above mixture into the barrel of the injection molding machine, the temperature in the front area of the barrel is 185°C, and the feeding temperature is 240°C; figure 1 For the corresponding injection mold, the temperature of each mold area is as follows: the oil temperature in the bottle bottom mold area is 130°C, and an oil pipe is installed; the oil temperature in the bottle shoulder mold area is 100°C, and an oil pipe is installed; the bottle body mold area is equipped with a There are multiple oil pipes, and the oil temperature of the oil pipe at the bottom is 68°C, and the oil temperature of the rest of the oil pipes is 130°C; the oil in the bottle bottom mold area, bottle shoulder mold area and bottle body ...

Embodiment 3

[0054] A kind of anti-spray code blooming plastic packaging bottle, its volume is 500mL, and it is processed by following process:

[0055] Ingredients: Take 1000g of high-density polyethylene, 20g of color masterbatch, mix well;

[0056] Injection molding: put the above mixture into the barrel of the injection molding machine, the temperature in the front area of the barrel is 180°C, and the feeding temperature is 250°C; figure 1 For the corresponding injection mold, the temperature of each mold area is as follows: the oil temperature in the bottle bottom mold area is 120°C, and an oil pipe is installed; the oil temperature in the bottle shoulder mold area is 80°C, and an oil pipe is installed; the bottle body mold area is equipped with a There are multiple oil pipes, and the oil temperature of the oil pipe at the bottom is 50°C, and the oil temperature of the rest of the oil pipes is 120°C; the oil in the bottom mold area, bottle shoulder mold area and bottle body mold are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com