Full-automatic box filling machine

A cartoning machine, fully automatic technology, applied in the direction of packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

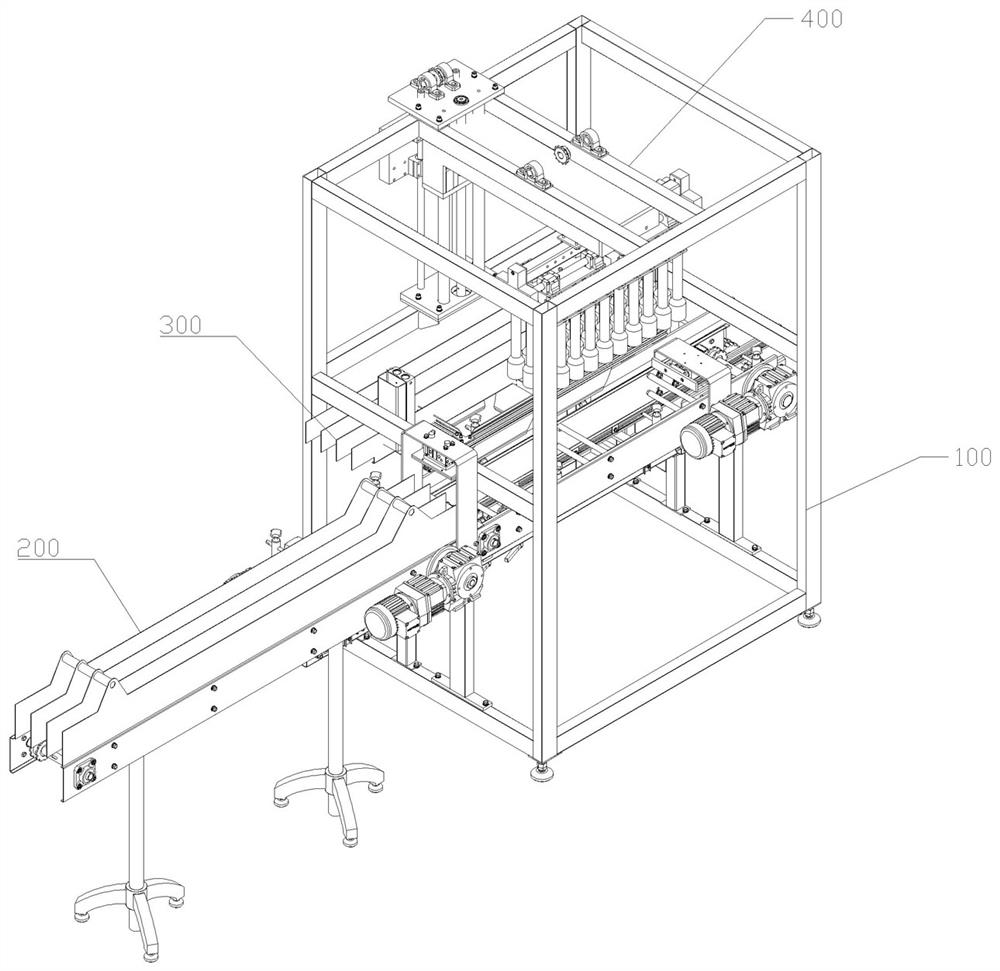

[0022] Combine below Figure 1 to Figure 5 The technical solutions provided by this application are described in more detail.

[0023] According to a specific embodiment of the present application, a fully automatic box packing machine includes a frame 100, a feeding line 200, a box feeding line 300 and a box packing mechanism 400, wherein the feeding line 200 and the box feeding line 300 follow a preset path Keeping a certain acute angle α, the packing mechanism 400 grabs the materials from the feeding line 200 , and then transfers the materials to the case feeding line 300 , and finally transports the packed materials away through the case feeding line 300 .

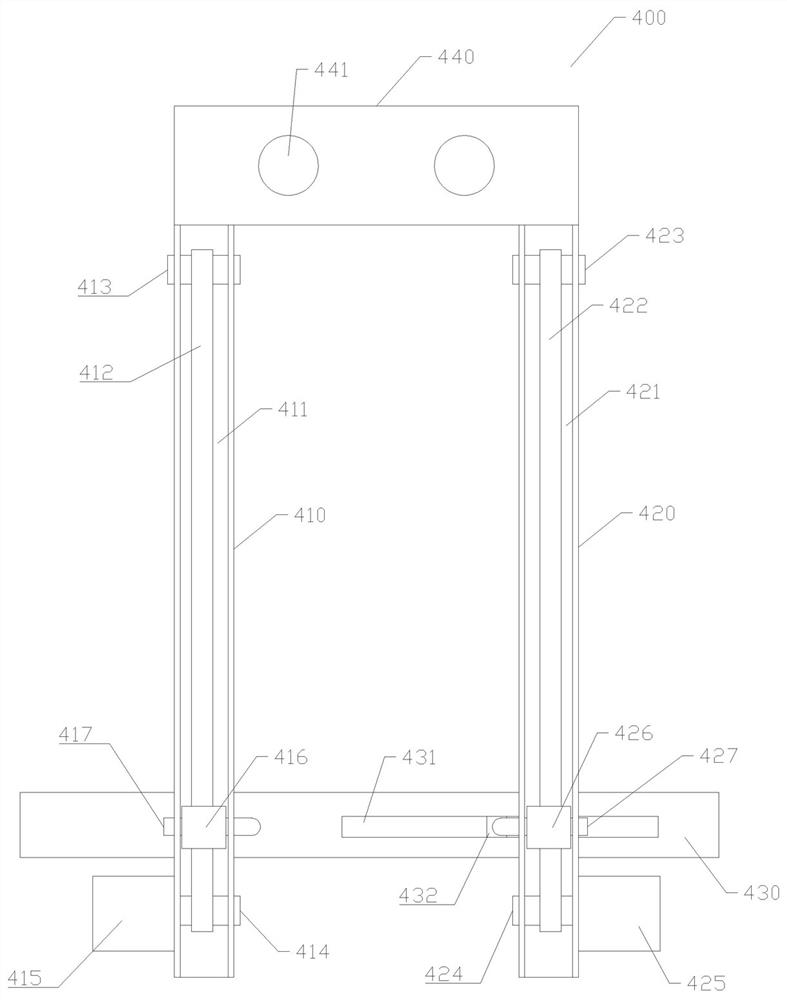

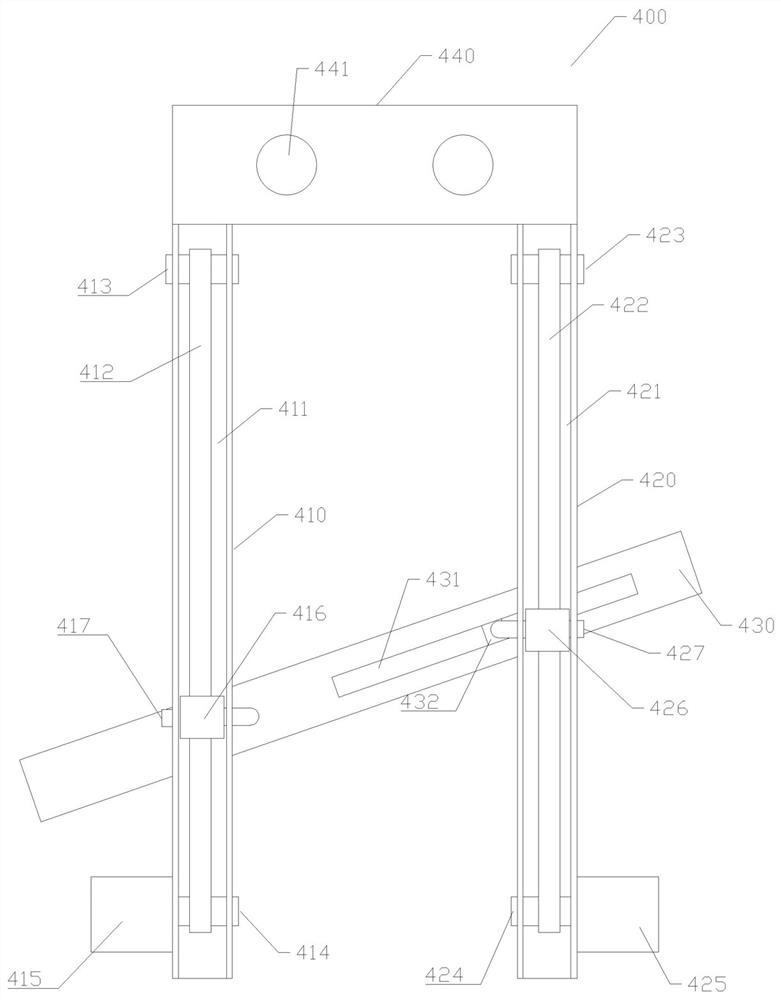

[0024] Specifically, the packing mechanism 400 includes a first support arm 410 and a second support arm 420 parallel to each other, and a grabbing plate 430 suspended below the two supporting arms, and a suction cup assembly is arranged under the grabbing plate 430 . For grabbing materials. Wherein, the first suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com