Device for adjusting warhead missile body parameters through dry gas

A dry gas and warhead technology, applied to warheads, ammunition, offensive equipment, etc., can solve the problems that the counterweight blocks occupy the space of the front and rear cabins and affect the function of the front and rear cabins, and achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

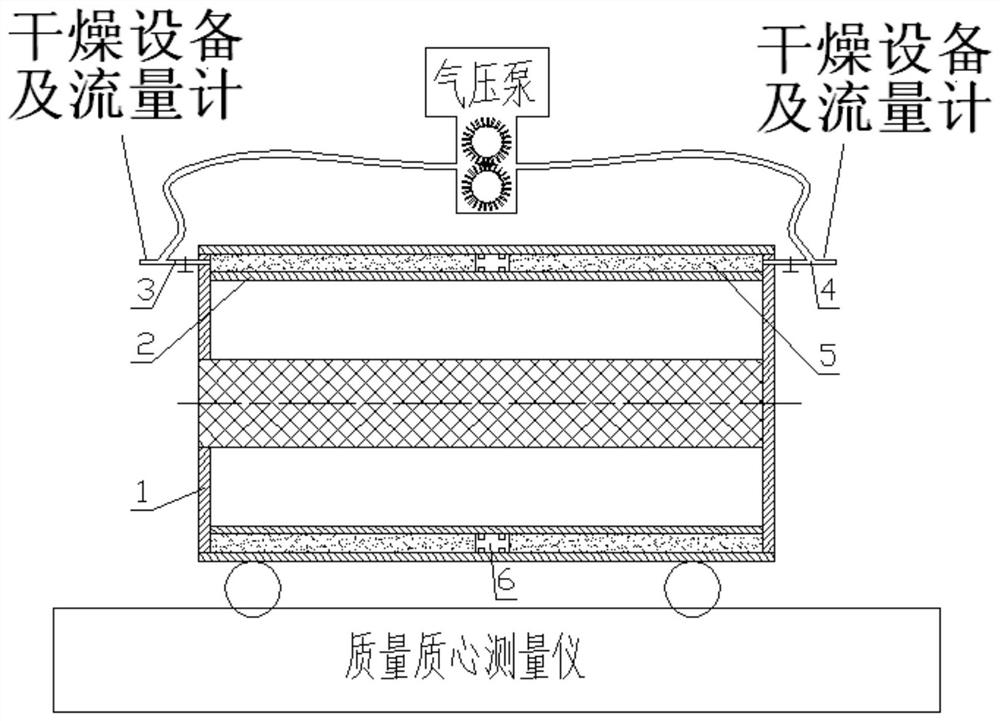

[0051] Such as figure 1 As shown, the present embodiment provides a device that utilizes dry gas to realize the adjustable parameters of the warhead body, including a warhead shell 1, which is characterized in that it also includes an annular compartment 2, a gas filling pipe 3 at the left end, a gas filling pipe 4 at the right end, Compress active gas 5, stopper 6, and drying equipment and flowmeters matching with gas filling pipe 3 at the left end and gas filling pipe 4 at the right end;

[0052] The warhead shell 1 is a liquid-phase charged warhead shell, and the warhead shell 1 is a revolving body. The warhead shell 1 is composed of a left end cover, a right end cover, a shell and a throwing device. The cover is a first concentric circular plate, the left end surface of the first concentric circular plate of the warhead shell 1 is the first left end concentric circle plane, and the right end surface of the first concentric circular plate of the warhead shell 1 is the first...

Embodiment 2

[0086] Such as figure 1 As shown, the present embodiment provides a device that utilizes dry gas to realize the adjustable parameters of the warhead body, including a warhead shell 1, which is characterized in that it also includes an annular compartment 2, a gas filling pipe 3 at the left end, a gas filling pipe 4 at the right end, Compress active gas 5, stopper 6, and drying equipment and flowmeters matching with gas filling pipe 3 at the left end and gas filling pipe 4 at the right end;

[0087] The warhead shell 1 is a liquid-phase charged warhead shell, and the warhead shell 1 is a revolving body. The warhead shell 1 is composed of a left end cover, a right end cover, a shell and a throwing device. The cover is a first concentric circular plate, the left end surface of the first concentric circular plate of the warhead shell 1 is the first left end concentric circle plane, and the right end surface of the first concentric circular plate of the warhead shell 1 is the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com