System and method for jointly producing olefin by alkane catalytic dehydrogenation and light hydrocarbon catalytic cracking

A catalytic dehydrogenation and catalytic cracking technology, which is applied in the direction of chemical instruments and methods, hydrocarbon cracking to produce hydrocarbons, hydrocarbons, etc., can solve problems such as insufficient supply of raw materials, reduce raw material supply pressure and equipment investment, reduce The effect of equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

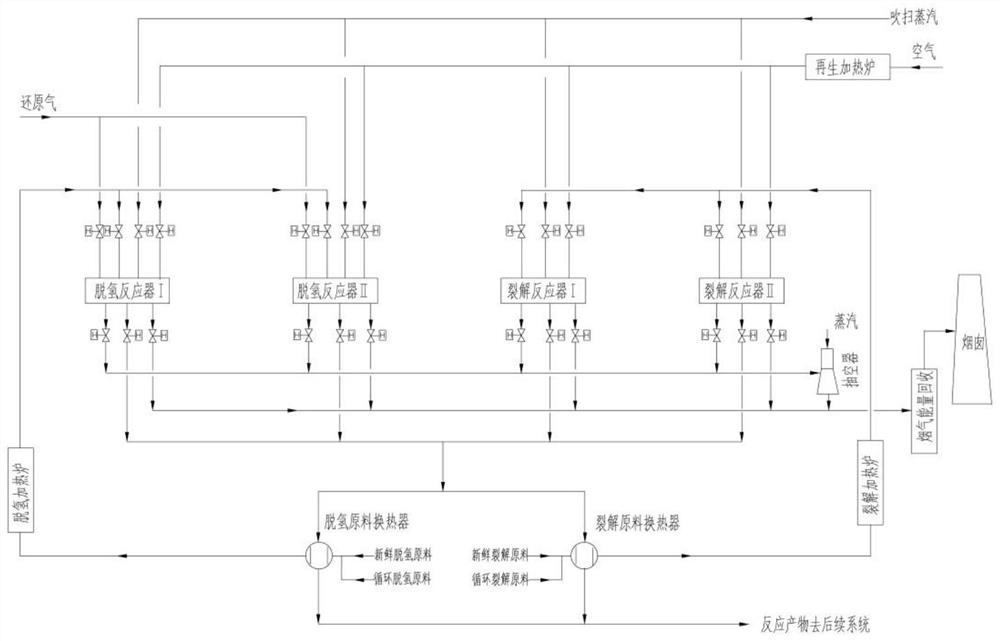

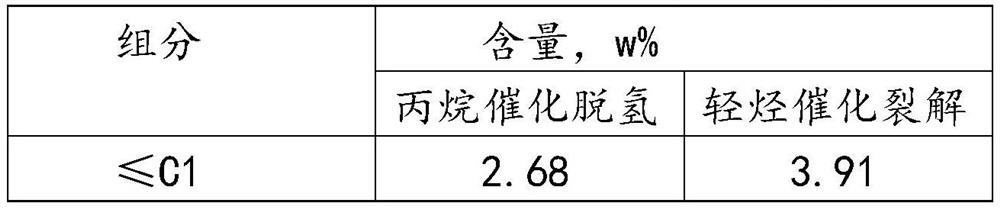

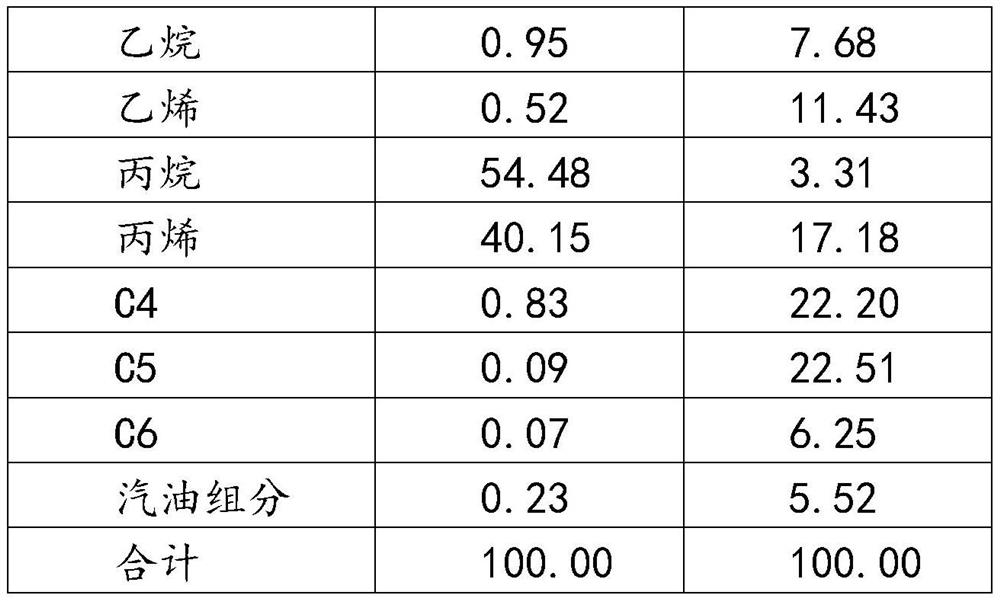

[0033] A 150,000 tons / year (output) propane catalytic dehydrogenation and light hydrocarbon catalytic cracking joint production of olefins unit (annual operating hours 8000 hours), using the attached figure 1 The reaction system and process flow shown include two propane catalytic dehydrogenation reactors and two light hydrocarbon catalytic cracking reactors. The propylene production capacity of propane catalytic dehydrogenation is 150,000 tons / year, which requires 174,500 tons / year of propane; 5 and C 6 The components are 436,600 tons / year.

[0034] The cycle period of reaction-purging-reheating-evacuation / reduction is 20 minutes, and the outlet temperature of the reheating air heating furnace is 620-660°C. The temperature of the upper layer of the propane catalytic dehydrogenation reactor is between 570 and 590°C at the beginning and end, and the temperature of the lower layer is between 560 and 580°C at the beginning and end; the temperature of the upper layer of the cata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com