Oil-water separation method based on hydrophilic oleophobic fabric

A hydrophilic and oleophobic, oil-water separation technology, applied in separation methods, liquid separation, chemical instruments and methods, etc., can solve problems such as refractory degradation and human health hazards, and achieve the effect of safe production process and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of above-mentioned hydrophilic oleophobic fabric disclosed by the present invention is as follows:

[0041] (1) Fiber surface quaternary ammonium salt pretreatment: first prepare polydiallyl dimethyl ammonium chloride aqueous solution, put it into the fabric, impregnate, squeeze, and dry;

[0042] (2) Preparation of sodium perfluoropolyether carboxylate aqueous solution: Add sodium hydroxide aqueous solution dropwise to perfluoropolyether carboxylic acid for neutralization reaction to obtain sodium perfluoropolyether carboxylate aqueous solution;

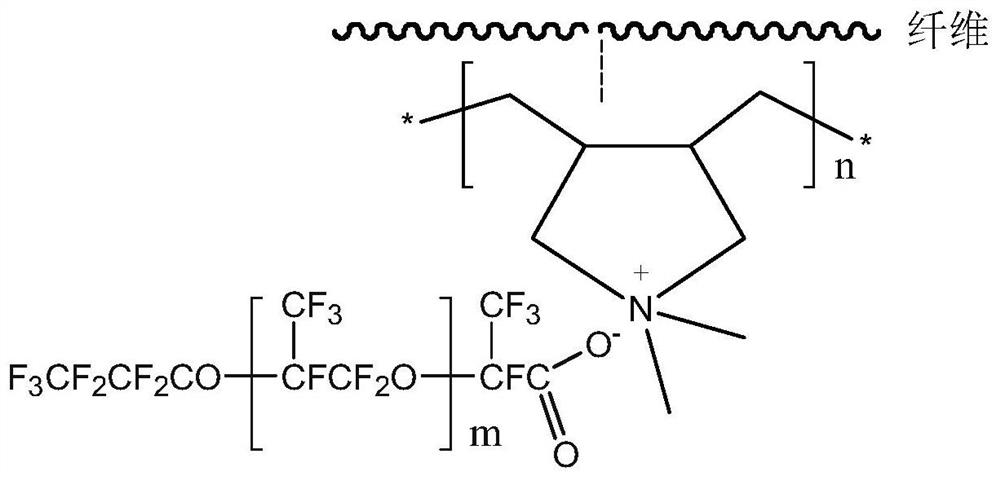

[0043] (3) Put the dried quaternized fabric into the aqueous solution of perfluoropolyether sodium carboxylate for exchange reaction; then take out the fluorinated fabric, wash it with water, and dry it to obtain a hydrophilic and oleophobic fabric. The fiber surface coating in the fabric is chemically Structural diagram see figure 1 .

Embodiment 1

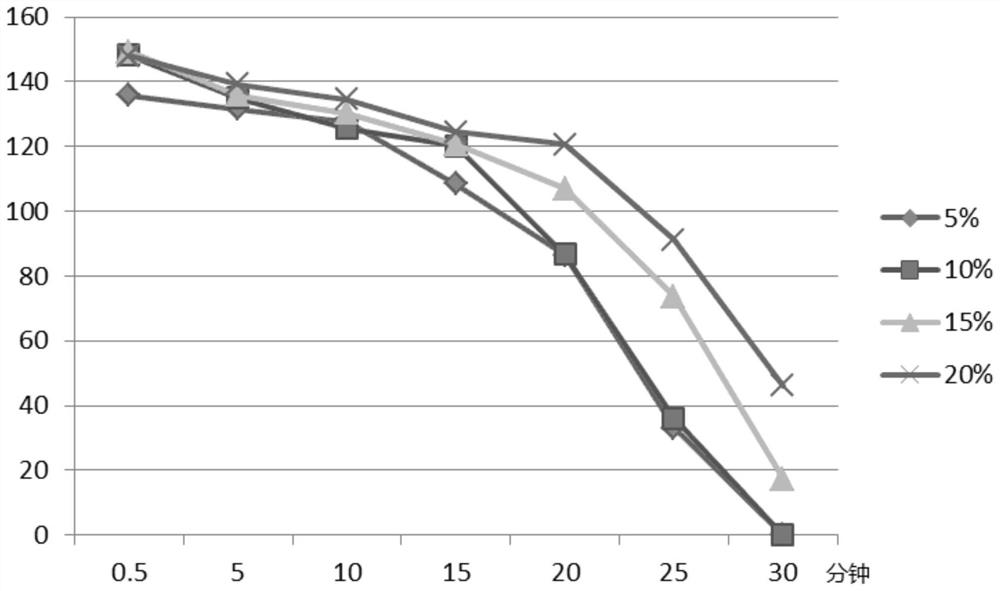

[0047] 25g of polydiallyldimethylammonium chloride (polydiallyldimethylammonium chloride was purchased from Kunshan Shengan Biotechnology Co., Ltd., the model is D1UL (molecular weight 230,000-250,000), the following examples The same) was dissolved in 475g of water, and prepared into a polydiallyldimethylammonium chloride aqueous solution with a concentration of 5.0wt%. Then, 20g of polyester fabric was put into it, soaked for 30 minutes, and squeezed to control the squeeze rate to 50%. Dry at 50°C for 1 hour, weigh the fabric, and measure the primary weight gain rate of the fabric to be 4.4%; the fabric cannot be separated from oil and water;

[0048] Dissolve 0.4g of sodium hydroxide in 108g of water to prepare an aqueous sodium hydroxide solution with a mass concentration of 0.37%;

[0049] Under normal stirring, add 12 g of K-type perfluoropolyether carboxylic acid with a number average molecular weight of 3000 to a 500mL beaker, cool to 5°C, add the above aqueous sodium ...

Embodiment 2

[0057] Dissolve 50g of polydiallyldimethylammonium chloride in 450g of water to prepare a polydiallyldimethylammonium chloride aqueous solution with a concentration of 10.0%, then put 20g of polyester fabric into it, soak it for 30min, and squeeze the liquid , control the squeeze rate to 50%, dry at 50°C for 1h, weigh the fabric, and measure the primary weight gain rate of the fabric to be 6.2%. Treat the fabric to test infrared, see the results Figure 4 Curve PDA, visible fiber surface at 3500~3350 cm -1 Strong and broad characteristic absorption peaks of quaternary ammonium salts appeared in the range. Figure 5 The surface SEM image and EDS element distribution map of the treated polyester fabric were measured, among which, the C element was 64.031%, the N element was 3.148%, and the O element content was 32.821%. Since the polyester fabric does not contain N element, the test results show that polydiallyl two Methyl ammonium chloride has been coated on the fiber surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com