Ultra-high-speed integrated motor with internal inductance capable of being steplessly adjusted

A stepless adjustment, ultra-high-speed technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve problems such as the complexity of the motor working system, the complexity of the motor working system, and the limitation of the working efficiency of the motor, so as to increase high reliability, Effect of improving work efficiency and simplifying work system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

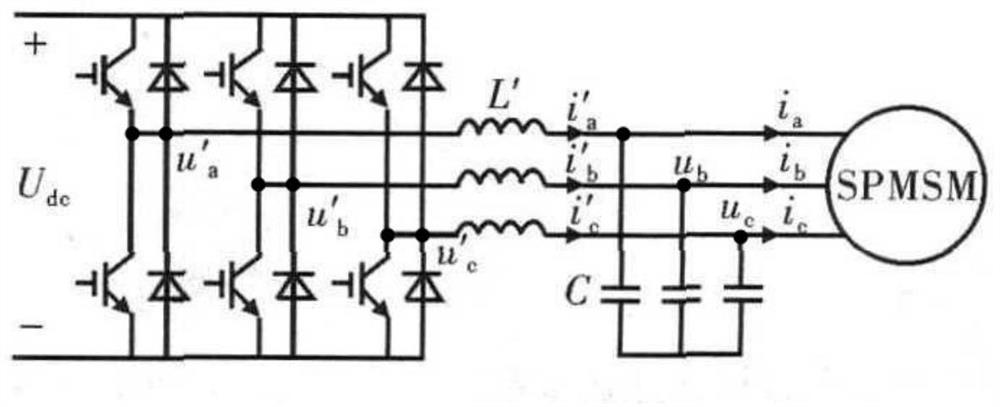

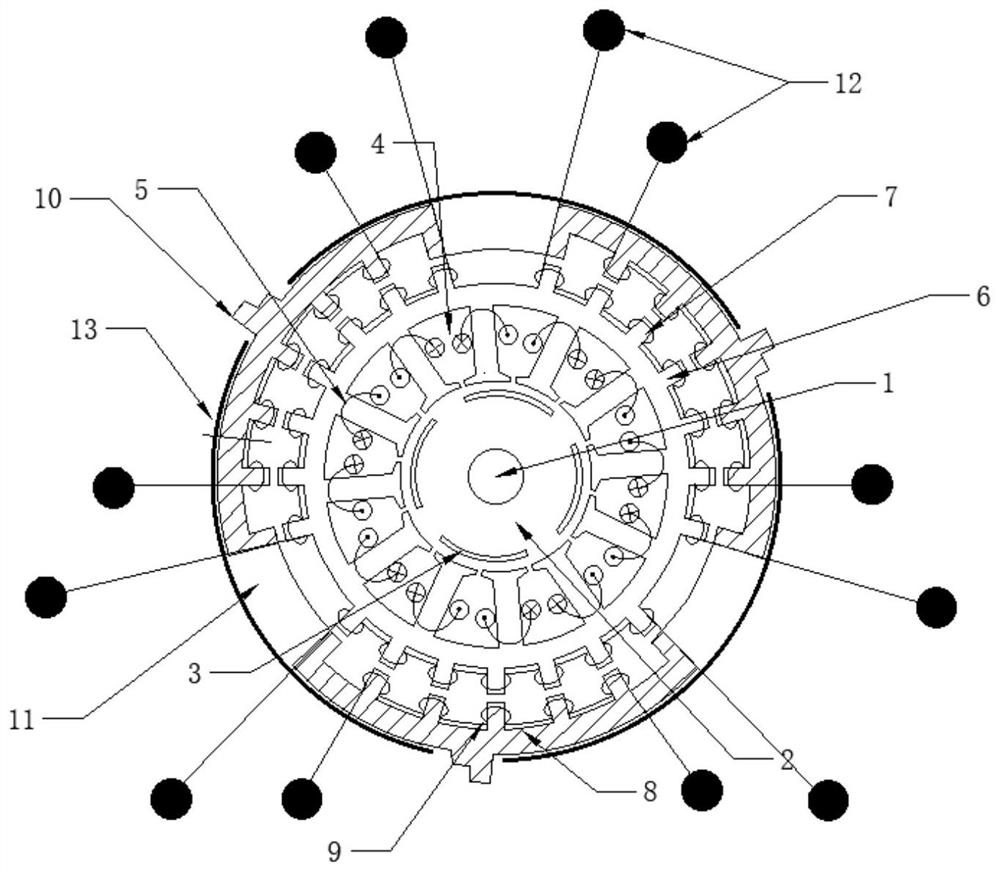

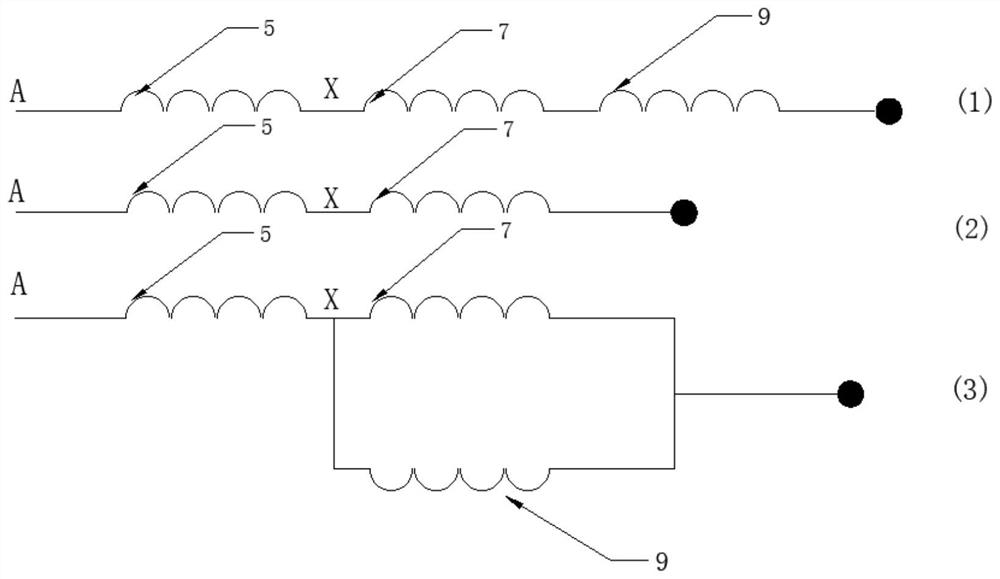

[0030] The invention proposes an ultra-high-speed integrated motor whose internal inductance can be adjusted steplessly. A reactor is placed inside the motor casing, and the inductance of the reactor can be adjusted freely. In terms of nature, the inductance of this reactor is not the winding of the motor itself, which belongs to the external winding, but in terms of structure, the reactor is located inside the motor casing and integrated with the motor. While ensuring the safe operation of the motor, it also improves the working efficiency of the motor and simplifies the entire working system of the motor.

[0031] The invention provides an ultra-high-speed integrated motor whose internal inductance can be adjusted st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com