High-temperature-resistant polyethylene wood plywood and preparation method thereof

A technology of high temperature resistant polyethylene and wood plywood, applied in the field of wood plastic composite materials, can solve the problems of low tensile strength and impact strength of wood plastic board, small interface bonding force, poor thermal conductivity, etc., to improve mechanical strength and hardness , Strong compatibility, the effect of improving mechanical strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

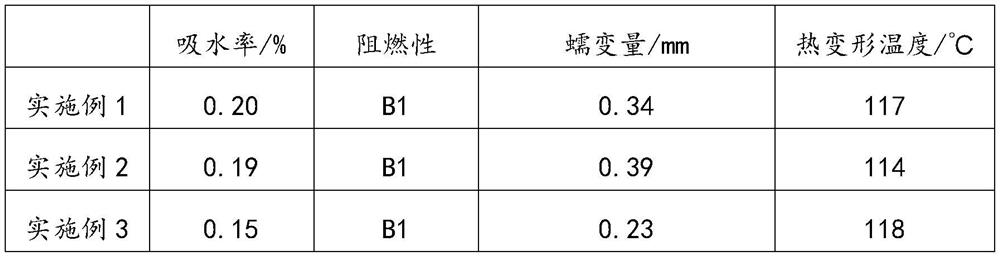

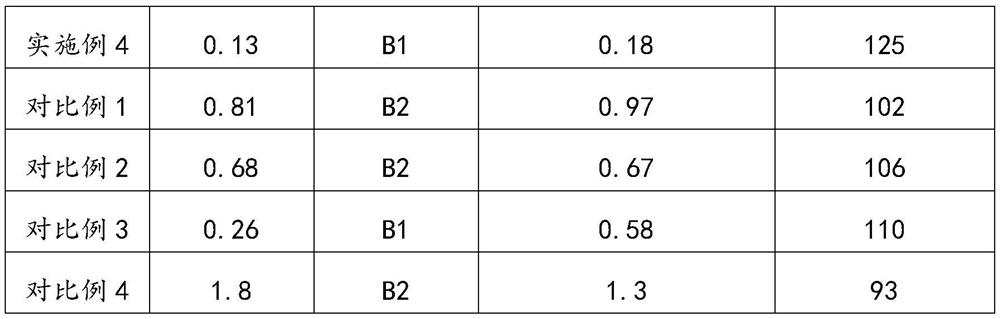

Examples

Embodiment 1

[0031] A high-temperature-resistant polyethylene wood plywood, which is composed of the following raw materials in parts by weight: 25 parts of modified polyethylene resin, 40 parts of eucalyptus wood powder, 20 parts of recycled bamboo plastic powder, 5 parts of polyethylene wax, aluminate 0.8 parts of joint agent, 5 parts of aluminum nitride powder, 3 parts of organic bentonite, 0.6 parts of triphenyl phosphite and 0.6 parts of n-pentane. The preparation method of the high temperature resistant polyethylene wood plywood comprises the following specific steps:

[0032] S1. Add 120-mesh aluminum nitride powder, aluminate coupling agent and 50 parts of xylene into the reaction kettle, stir at 100°C for 4-6 hours, filter, wash twice with ethanol solution, and dry to prepare Obtain surface-modified aluminum nitride;

[0033] S2. Add 100-mesh eucalyptus powder into 75% ethanol solution, soak at 50°C for 4 hours, add the above-mentioned surface-modified aluminum nitride, stir for ...

Embodiment 2

[0040] A high-temperature-resistant polyethylene wood plywood, which is composed of the following raw materials in parts by weight: 40 parts of modified polyethylene resin, 30 parts of eucalyptus wood powder, 10 parts of recycled bamboo plastic powder, 3 parts of polyethylene wax, aluminate 1.5 parts of joint agent, 10 parts of aluminum nitride powder, 4 parts of organic bentonite, 0.3 parts of acid lauryl phosphite and 1.2 parts of n-hexane. The preparation method of the high temperature-resistant polyethylene wood plywood is the same as that in Example 1, the only difference is that the amount of xylene added in the S1 step is 80 parts.

[0041] The preparation method of above-mentioned modified polyethylene comprises the following steps:

[0042] (1) Add 50 parts of LLDPE and 150 parts of anisole into the reaction kettle, heat to 70-80°C, stir for 0.5h, then add 0.25 parts of BPO and 2.5 parts of tricresyl phosphate, and slowly heat up to Stir at 100°C for 2-3 hours to obt...

Embodiment 3

[0047] A high-temperature-resistant polyethylene wood plywood, which is composed of the following raw materials in parts by weight: 30 parts of modified polyethylene resin, 35 parts of eucalyptus wood powder, 15 parts of recycled bamboo plastic powder, 4 parts of polyethylene wax, aluminate 1 part of joint agent, 8 parts of aluminum nitride powder, 5 parts of organic bentonite, 0.5 part of acid lauryl phosphite and 1.5 parts of petroleum ether. The preparation method of the high-temperature-resistant polyethylene wood plywood is the same as that in Example 1, the only difference is that the amount of xylene added in the S1 step is 72 parts.

[0048] The preparation method of above-mentioned modified polyethylene comprises the following steps:

[0049] (1) Add 50 parts of LLDPE and 120 parts of anisole into the reaction kettle, heat to 70-80°C, stir for 0.5h, then add 0.25 parts of BPO and 1.5 parts of tricresyl phosphate, and slowly heat up to Stir at 100°C for 2-3 hours to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com