Multi-functional overflow groove assembly for steel belt cooling machine

A steel strip cooling and overflow tank technology, applied in the direction of coating, etc., can solve the problems of not being able to obtain multiple strip products at the same time, increase the difficulty of maintenance, and cannot change the width, so as to achieve convenient replacement, improve production efficiency, The effect of increasing utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

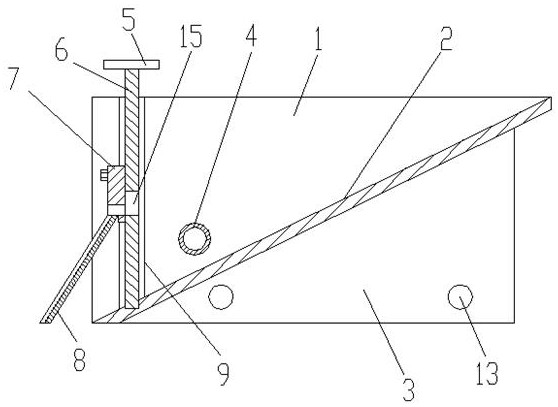

Embodiment 1

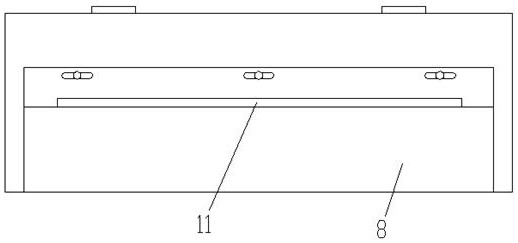

[0030] like image 3 As shown, when one guide hole 11 is used, the degree of coincidence (lateral misalignment) between the guide hole 11 and the overflow square hole 15 can be changed by laterally shifting the flow control plate 7, thereby changing the width of the sheet product;

Embodiment 2

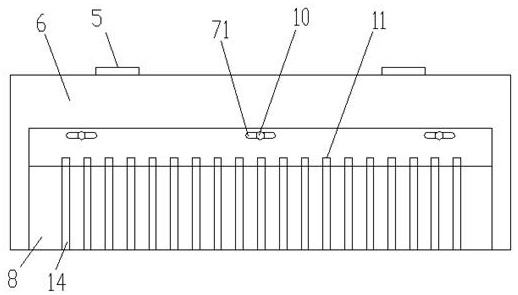

[0032] like figure 1 and 2 As shown, a plurality of guide holes 11 are used, so that multiple fluids are output synchronously, and when there are multiple guide holes 11, the top surface of the guide plate 8 is concavely provided with guide grooves corresponding to the guide holes 11 one-to-one. 14. A plurality of fluids are sent to the surface of the steel belt of the steel belt cooler through the diversion groove 14, and after cooling and solidification, a plurality of strip-shaped products are formed to improve the production efficiency.

[0033] In this embodiment, in order to ensure the fluidity of the fluid in the overflow tank, the overflow tank is provided with a hot oil pipeline 4 that penetrates through the two side shields 1 . The hot oil pipeline 4 is located above the bottom plate 2, and the hot oil Both ends of the pipeline 4 are connected with a heat transfer oil circulation pipeline to heat the fluid in the overflow tank.

[0034] To sum up, the multifunction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com