Thermal power plant closed water system cleaning and film forming system and operation method

A technology of closed water and thermal power plants, applied in boiler cleaning devices, flushing, cleaning heat transfer devices, etc., can solve problems that affect the safe operation of units and are difficult to eradicate, achieve good cleaning effects, improve safety, and film formation good quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is further described below in conjunction with accompanying drawing:

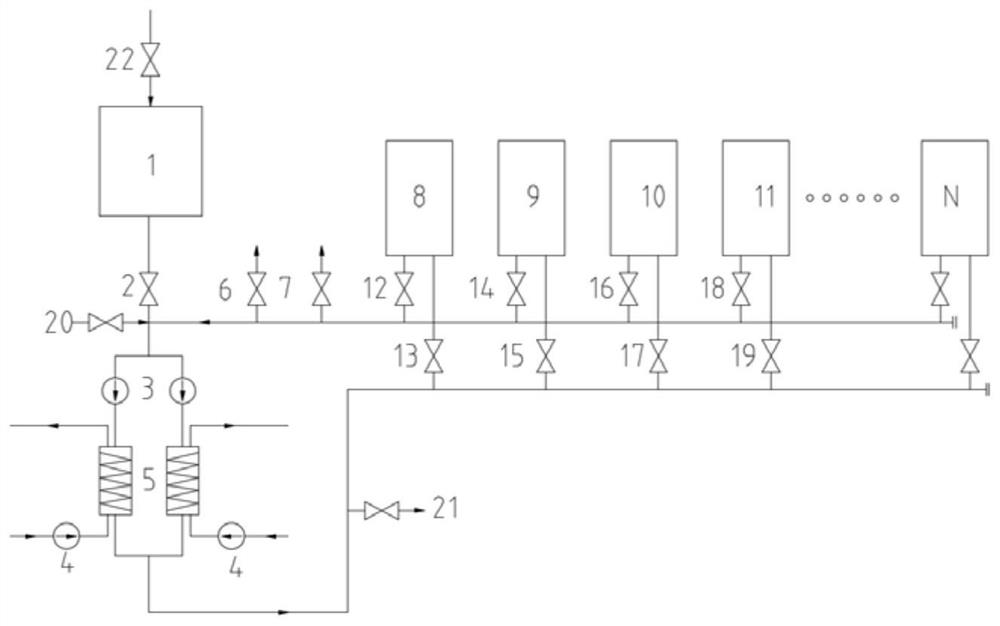

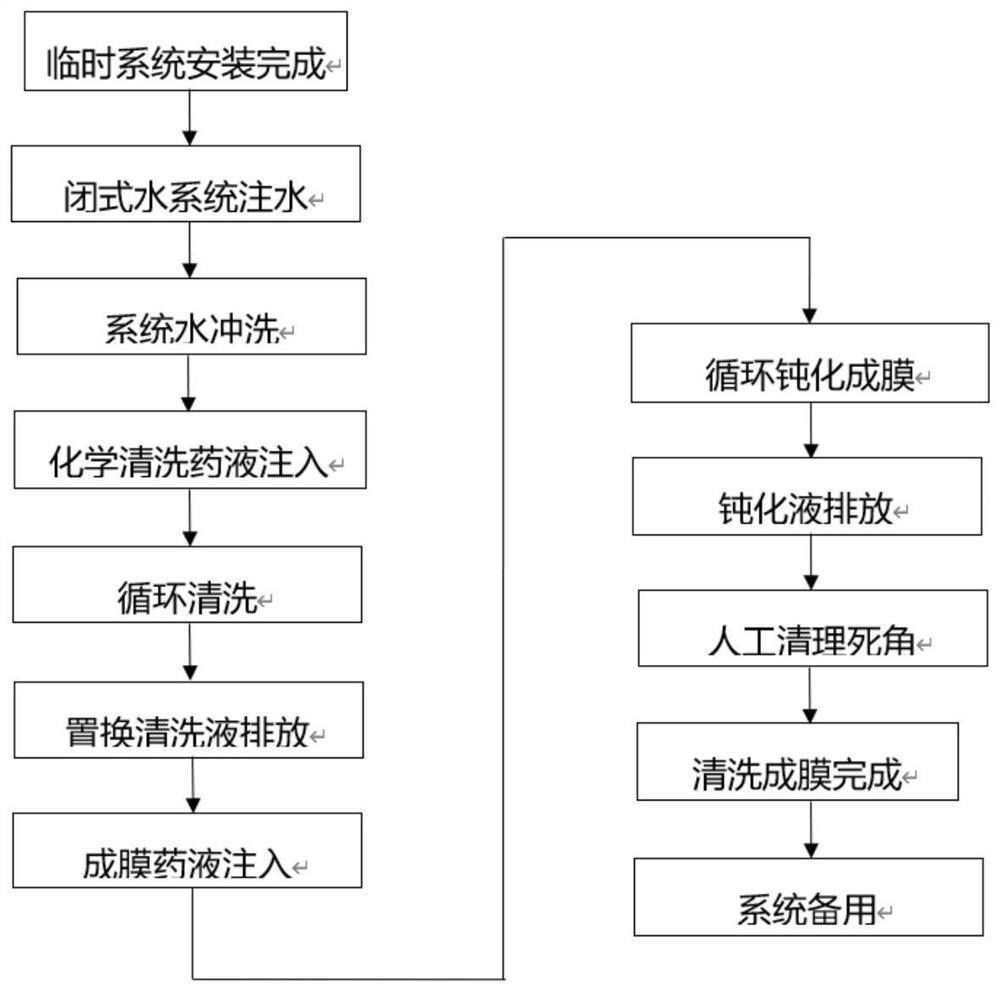

[0032] see Figure 1 to Figure 2 , a thermal power plant closed water system cleaning film forming system, including a high-level expansion tank 1, a closed water pump 3, a heat exchanger 5 and a number of closed water users; the high-level expansion tank 1 is connected to the inlet of the heat exchanger 5 through a pipeline, A closed water pump 3 is arranged on the pipeline between the high expansion water tank 1 and the heat exchanger 5; the outlet of the heat exchanger 5 is connected to the outlet pipeline, and the return water pipeline is connected between the high expansion water tank 1 and the closed water pump 3; the water outlet pipeline A number of closed water users are arranged between the water return pipeline and the water return port of each closed water user is connected to the return water pipeline, and the water inlet of each closed water user is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com