Adsorption system and method for VOCs solid-phase microextraction

An adsorption system and extraction technology, applied in the field of VOCs solid-phase microextraction adsorption system, can solve the problems of difficult to control gas concentration, high recovery rate, low detection limit, etc., to reduce the use of hoses, high recovery rate, Effect of low detection limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

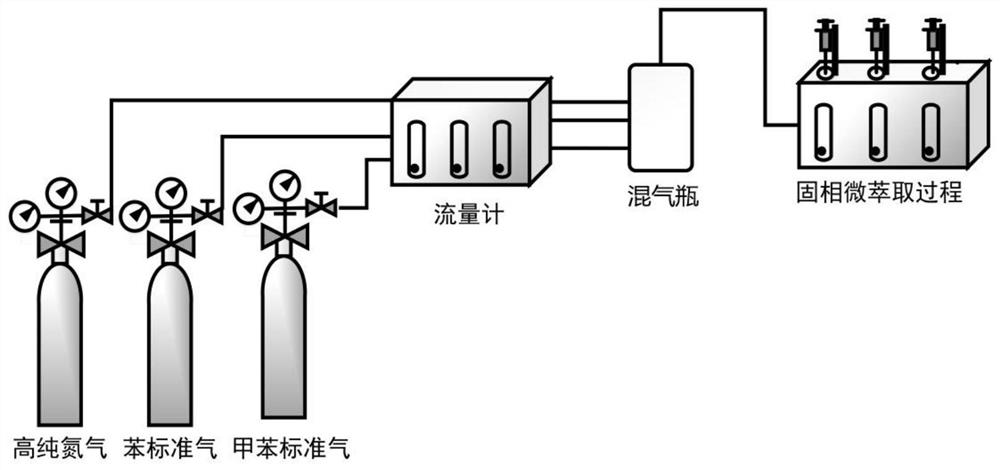

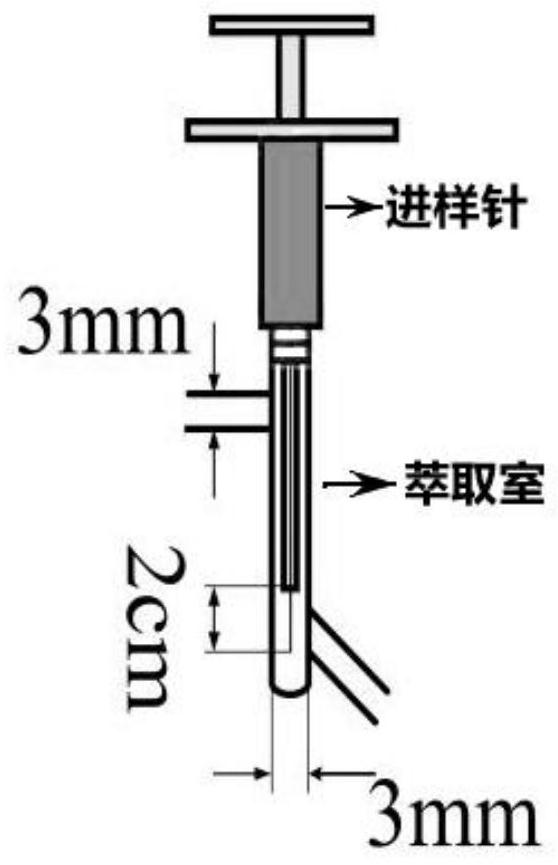

[0027] An adsorption simulation system for solid-phase microextraction of VOCs, the system includes: a gas mixing bottle, an extraction chamber, a flow meter and several high-pressure gas bottles. Wherein, each high-pressure gas bottle communicates with the gas inlet of the gas mixing bottle through a pipeline, and a flow meter is arranged on the pipeline between the high-pressure gas bottle and the gas mixing bottle, and the gas outlet of the gas mixing bottle is connected with the extraction chamber through a pipeline.

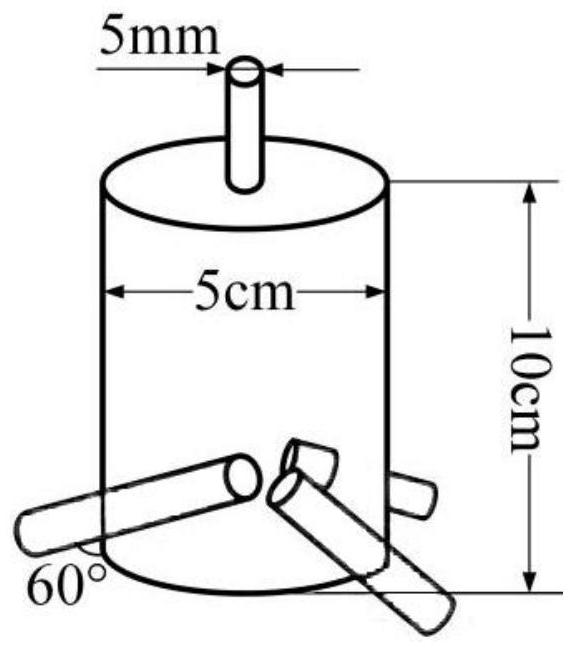

[0028] The quantity of gas to be mixed is consistent with the gas inlet quantity of the high-pressure gas bottle and the gas mixing bottle. Mixed gases include: nitrogen, benzene standard gas and toluene standard gas. High-pressure gas cylinders include: nitrogen high-pressure gas cylinders, benzene standard gas high-pressure gas cylinders and toluene standard gas high-pressure gas cylinders. There are three gas inlets on the side wall of the lower part of ...

Embodiment 2

[0033] A VOCs solid-phase microextraction simulation method, the method uses the system of embodiment 1, comprising:

[0034] (1) No extraction fiber is installed in the extraction chamber. Open the high-pressure gas cylinders of nitrogen, benzene and toluene standard gas in sequence, control the flow meter, and prepare a suitable concentration of gas. The three gases are mixed in a certain proportion to ensure The gas flow rate is the same to avoid gas mixing disorder (that is, the sum of the flow rates of the three gases and the total flow rate of the gas flowing through the three branch benzene standard gas, toluene standard gas, and high-purity nitrogen high-pressure gas cylinders to the extraction chamber are The same), let the gas flow through the entire gas path, and perform a certain pre-adsorption when the gas is stable. Since the extraction chamber and the gas mixing bottle are made of glass, and the connecting pipes are made of polytetrafluoroethylene hard tubes, the...

Embodiment 3

[0041] A VOCs solid-phase microextraction method, which is basically the same as in Example 2, the difference is that the diameter of the gas mixing bottle is 5 cm, and the diameter of the extraction chamber is 5 mm, and its extraction effect is better than that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com