Sandwich pie and production process thereof

A production process and pie technology, applied in the field of sandwich pie and its production process, can solve the problems of reducing the risk of cardiovascular and cerebrovascular diseases, delaying the speed of glucose absorption, and increasing the residence time of food, so as to reduce the use of chemical raw materials, The effect of reducing loss and damage, retaining nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

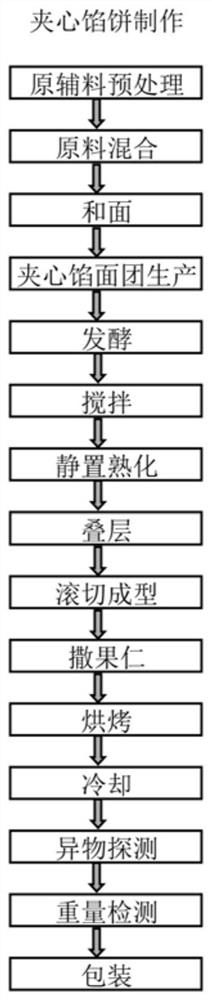

[0053] Cheese-filled Praline Tart Production:

[0054] 1) Pretreatment of raw and auxiliary materials: Weigh 20 parts of cheese powder and 5 parts of sliced nuts, cut and finely grind the flavor raw material powder and sliced nuts for pretreatment, and set aside;

[0055] 2) Mixing: Weigh 20 parts of palm oil, 40 parts of sugar, 400 parts of flour, 70 parts of water, 10 parts of malt syrup, 5 parts of compound phosphate, 0.3 parts of compound enzyme preparation, 10 parts of milk powder, and 2 parts of ammonium bicarbonate , 5 parts of salt, 1 part of compound leavening agent, 0.1 part of sodium metabisulfite, 0.2 part of food flavor, 12 parts of starch, 1.2 parts of soybean lecithin, and mix well;

[0056] 3) Kneading dough: Put the pretreated auxiliary materials in step 2) into a mixer for stirring. The mixing time is 30 minutes and mixed into dough, and three groups of dough are produced, and two groups of dough are reserved as the top embryo dough and the bottom embryo ...

no. 2 example

[0067] Sweet sandwich pie production:

[0068] 1) Pretreatment of raw and auxiliary materials: Weigh 15 parts of purple sweet potato powder and 20 parts of sliced nuts, and pretreat the flavor raw material powder and sliced nuts by shearing and fine grinding, and set aside;

[0069] 2) Mixing: Weigh 32 parts of palm oil, 60 parts of sugar, 400 parts of flour, 50 parts of water, 5 parts of malt syrup, 2 parts of compound phosphate, 0.2 parts of compound enzyme preparation, 25 parts of milk powder, and 8 parts of ammonium bicarbonate , 4 parts of salt, 3 parts of compound leavening agent, 0.3 part of sodium metabisulfite, 0.2 part of food flavor, 6 parts of starch, 1 part of soybean lecithin, and mix well;

[0070] 3) Kneading dough: Put the pretreated auxiliary materials in step 2) into a mixer for stirring. The mixing time is 30 minutes and mixed into dough, and three groups of dough are produced, and two groups of dough are reserved as the top embryo dough and the bottom ...

no. 3 example

[0081] Crispy sandwich pie production:

[0082] 1) Pretreatment of raw and auxiliary materials: Weigh 20 parts of Moringa oleifera powder and 10 parts of sliced nuts, and pretreat the flavor raw material powder and sliced nuts by shearing and fine grinding, and set aside;

[0083] 2) Mixing: Weigh 20 parts of palm oil, 45 parts of sugar, 300 parts of flour, 40 parts of water, 5 parts of malt syrup, 2 parts of compound phosphate, 0.2 parts of compound enzyme preparation, 10 parts of milk powder, and 15 parts of ammonium bicarbonate , 5 parts of salt, 2 parts of compound leavening agent, 0.1 part of sodium metabisulfite, 0.6 part of food flavor, 10 parts of starch, 0.5 part of soybean lecithin, and mix well;

[0084] 3) Kneading dough: Put the pretreated auxiliary materials in step 2) into a mixer for stirring. The mixing time is 30 minutes and mixed into dough, and three groups of dough are produced, and two groups of dough are reserved as the top embryo dough and the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com