Controllable jet-propelled sensor device and calibration method and system thereof

A sensor device and gas sensor technology, applied in the field of sensor monitoring, can solve the problems of low sensor processing accuracy, poor measurement performance, low measurement accuracy, etc., and achieve the effects of speeding up the detection and calibration process, improving the monitoring sensitivity, and improving the sensing sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

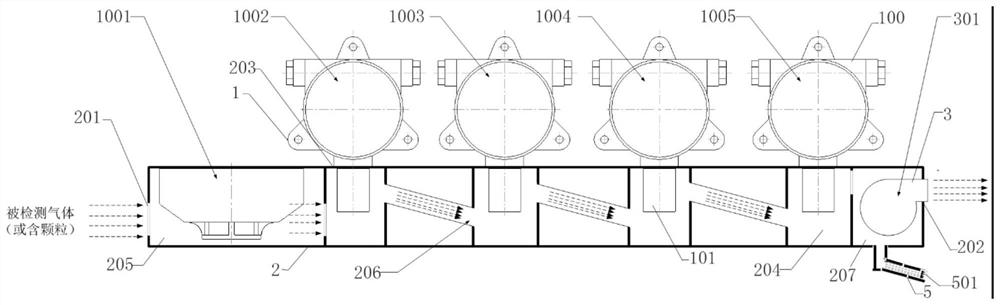

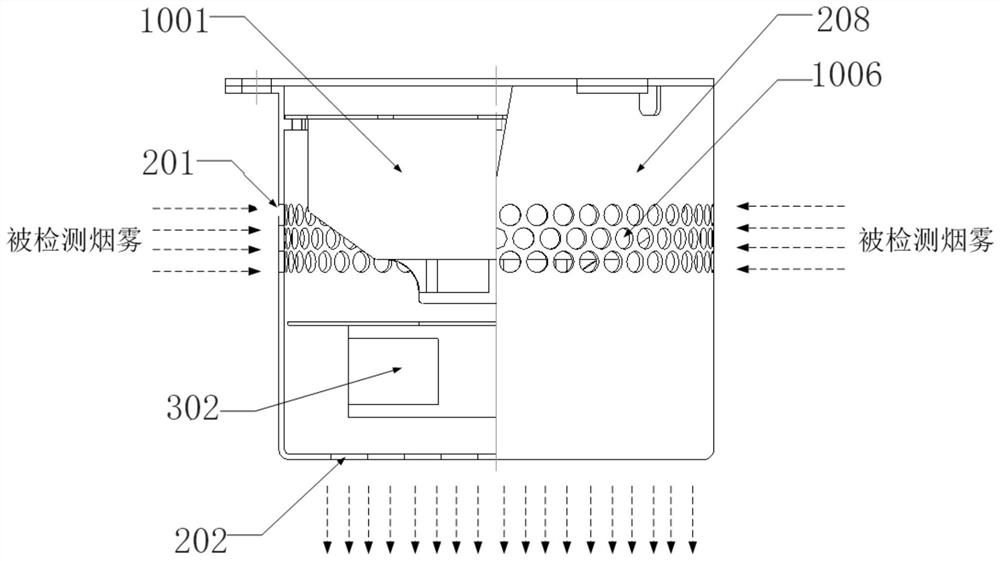

[0062] Such as figure 1 Shown, a controllable jet sensor device, comprising:

[0063] An induction device body 1 with one or more gas sensors 100; the probe end 101 of the induction device body 1 is configured with a gas flow channel 2;

[0064] An air suction device 3 is provided in the air flow channel 2, and the air suction device 3 is used to guide the external air flow to flow through the air flow channel 2;

[0065] The airflow passage 2 is provided with an outlet pipe 5 for generating impact airflow to the external monitored environment; the diameter of the outlet pipe 5 is smaller than the air inlet 201 of the airflow passage 2;

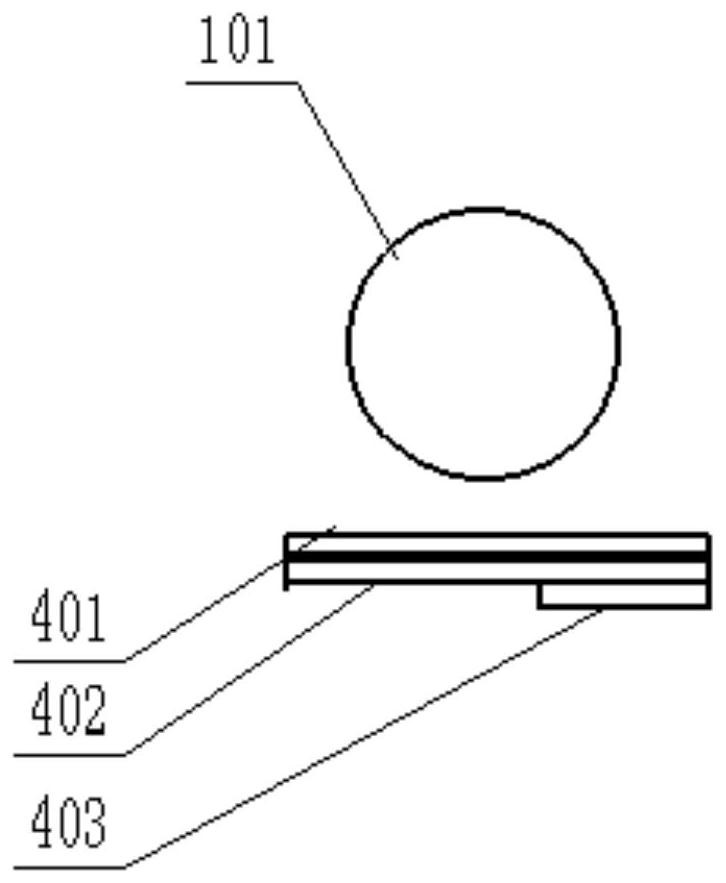

[0066] Further, the sensor device of the present invention also includes a self-calibration device 4 in the gas flow channel 2 for testing the measurement sensitivity of the gas sensor 100 by releasing a test gas.

[0067] The controllable air jet sensor device of the present invention constructs an airflow channel at the probe end of the g...

Embodiment 2

[0091] The present invention also provides a self-calibration method for a controllable jet sensor device, which is used for self-calibration of the controllable jet sensor device described in Embodiment 1 above; Figure 4 As shown, the method includes the steps of:

[0092] S1. Set up self-calibration rules for quantitative calculation of test gas heating release,

[0093] S2. Control the self-calibration device in the self-calibration gas sensor to start, and make the target sensor correspondingly collect the test gas parameters released by the self-calibration device;

[0094] S3. Perform self-calibration calculation according to the self-calibration rule according to the startup parameters of the self-calibration device and the obtained test gas parameters.

[0095] The method of the present invention aims to realize the self-calibration of the sensor on-line after the sensor is put into use, and a specific embodiment is:

[0096] Such as Figure 5 As shown, in the step...

Embodiment 3

[0108] The present invention also provides a controllable jet sensor self-calibration system, such as Figure 6 shown, including:

[0109] The sensor device is used to collect ambient gas data; it includes an induction device body with one or more gas sensors; the probe end of the induction device body is configured with an air flow channel; a suction device is arranged in the air flow channel, and the suction device is used for directing external airflow to flow through the airflow channel;

[0110] The airflow channel is provided with an outlet pipe for generating impact airflow to the external monitored environment; the diameter of the outlet pipe is smaller than the air inlet of the airflow channel;

[0111] There is also a self-calibration device in the gas flow channel, which is used to test the measurement sensitivity of the gas sensor by releasing test gas;

[0112] A self-calibration setting module for setting self-calibration rules for quantitative calculation of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com