Magnetic steel production molding cooling device and cooling method thereof

A technology of cooling device and magnetic steel, which is applied in the direction of separation methods, chemical instruments and methods, refrigerators, etc., can solve the problems that the magnetic steel cannot be guaranteed and is easy to be re-contaminated with impurities, so as to reduce the production cost, ensure the cooling effect, and avoid grinding The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

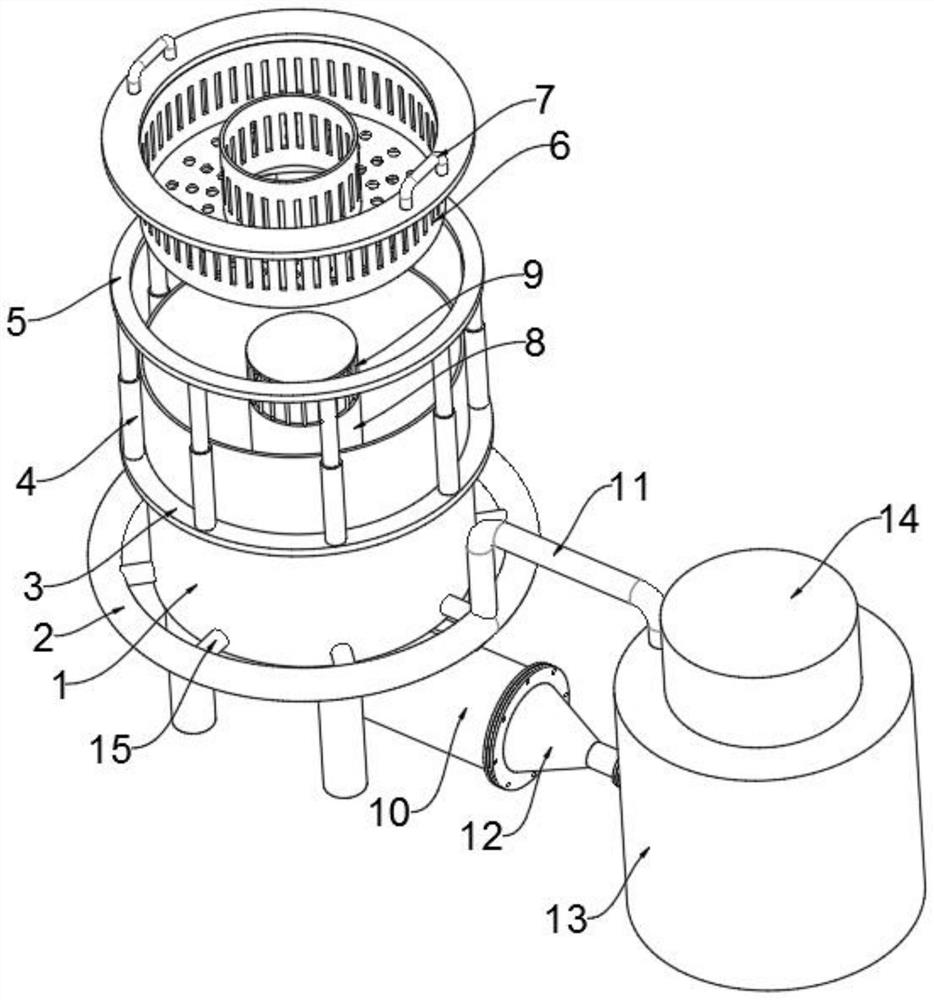

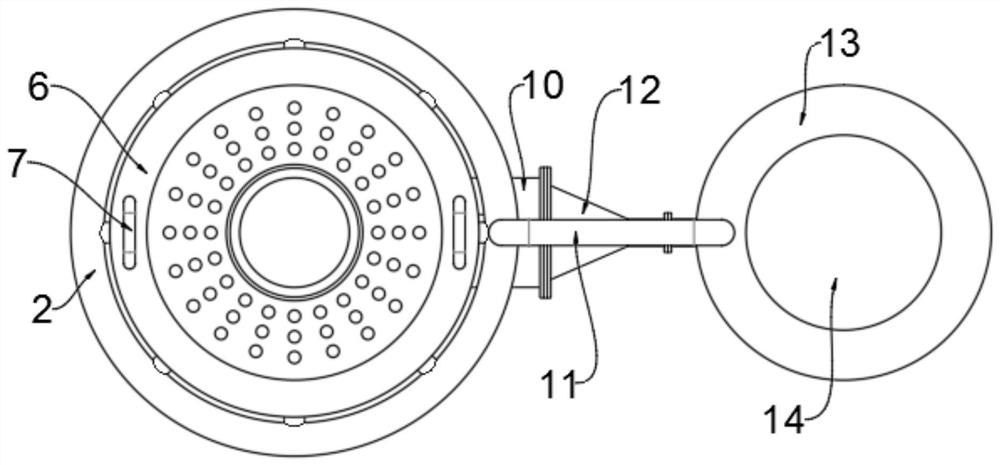

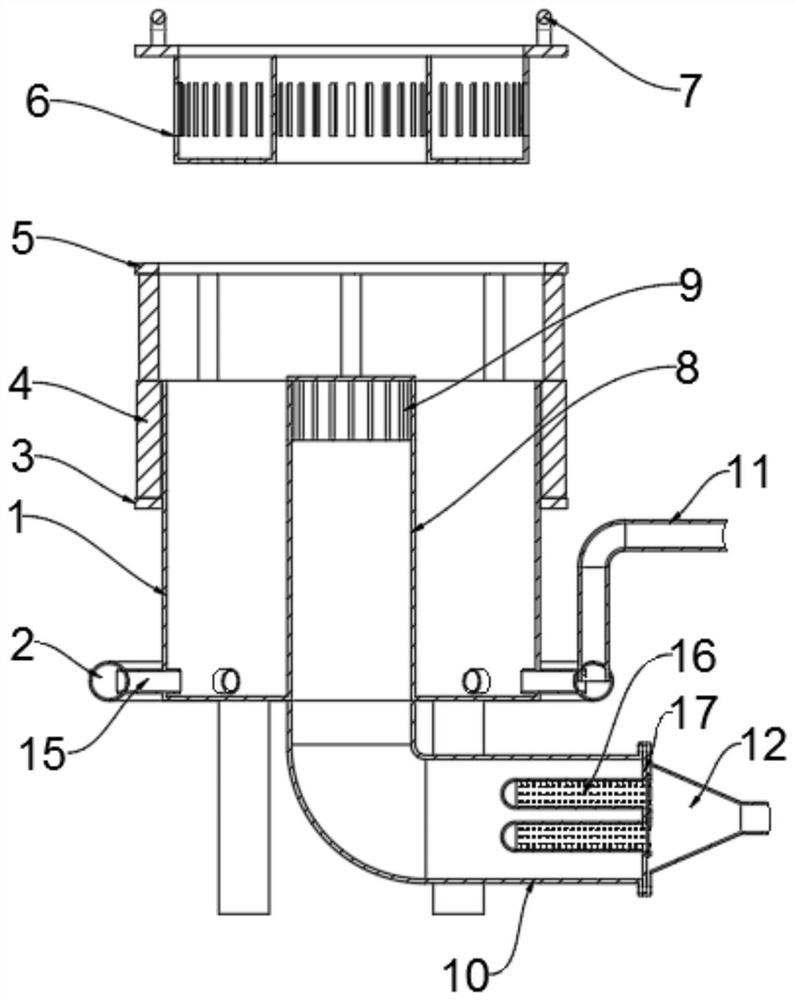

[0030] see Figure 1-5, an embodiment provided by the present invention: a magnetic steel production forming cooling device, comprising a magnetic steel forming cooling tank body 1, an inner guide tube 8 is fixedly connected to the inner central axis position of the magnetic steel forming cooling tank body 1, One end of the inner draft tube 8 is fixedly connected with a protective fence 9, and a through hole is provided at the central axis position of the bottom end of the magnetic steel forming cooling tank body 1, and the inner draft tube 8 corresponds to the position of the through hole, and the magnetic steel forming cooling tank body 1 is provided with a through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com