Method for detecting triethylamine in cefotaxime sodium and application of method

A technology of cefotaxime sodium and detection method, which is applied in the directions of measuring devices, instruments, scientific instruments, etc., can solve the problems of poor specificity, ineffective separation, cumbersome operation process, etc., and achieves the effect of good peak shape and separation degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

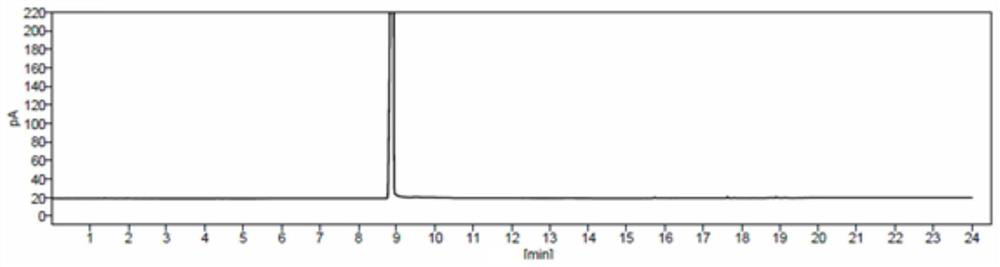

[0040] (1) Chromatographic conditions

[0041] Chromatographic column: Agilent CP-Sil 8 CB, 30m×0.32mm, 1.0μm;

[0042] Carrier gas flow rate: 3.0mL / min;

[0043] Heating program: maintain 50°C for 5 minutes, raise the temperature to 150°C at a rate of 10°C / min, then raise the temperature to 250°C at a rate of 25°C / min, and maintain for 3 minutes;

[0044] Injection port temperature: 200°C;

[0045] Detector temperature: 250°C;

[0046] Split ratio: 20:1;

[0047] Headspace furnace temperature: 80°C;

[0048] Headspace equilibration time: 30min;

[0049] Diluent: 4mol / L potassium hydroxide solution-dimethyl sulfoxide (1:1).

[0050] (2) Solution preparation

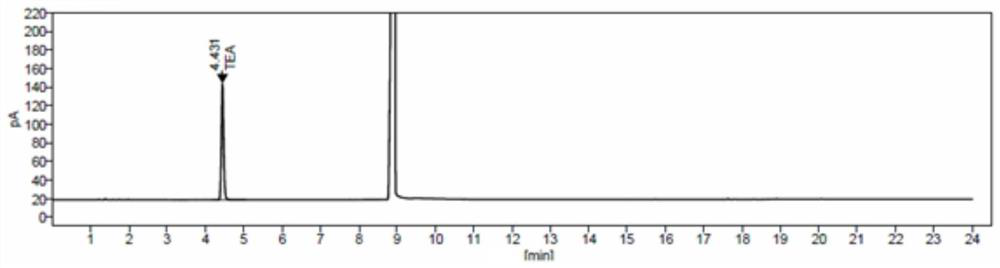

[0051] 1) Reference substance solution: weigh an appropriate amount of triethylamine, and use a diluent to prepare a solution containing about 32 μg / mL of triethylamine per 1 mL;

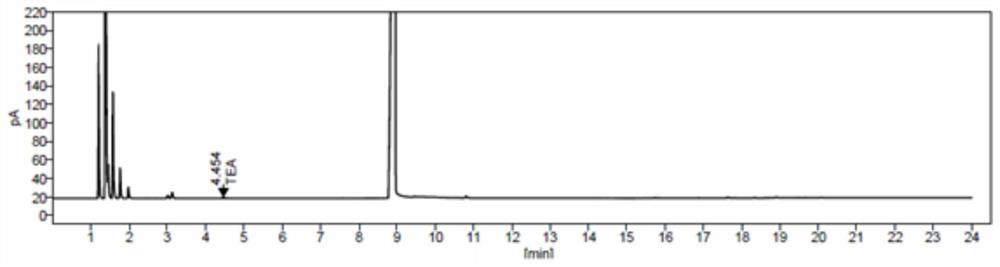

[0052] 2) Test solution: Weigh an appropriate amount of this product, and use a diluent to prepare a solution containing about 100 mg ...

Embodiment 2

[0079] Embodiment 2 residual triethylamine methodological verification

[0080] (1) Specificity

[0081] Prepare and test the specificity of the following solutions respectively:

[0082] Blank (prepared according to the method)

[0083] Control solution (prepared according to the method)

[0084] The test solution (prepared according to the method)

[0085] Exclusive solution (containing the test solution of limit concentration triethylamine)

[0086] Triethylamine positioning solution (limit concentration)

[0087] Methanol positioning solution (limit concentration)

[0088] Ethanol positioning solution (limit concentration)

[0089] Acetone positioning solution (limit concentration)

[0090] Dichloromethane positioning solution (limit concentration)

[0091] Ethyl acetate positioning solution (limit concentration)

[0092] Preparation of Specificity and Positioning Solutions

[0093] 1. Control stock solution: Accurately weigh 28.0mg of triethylamine, put it in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com