Coaxial telescopic high-altitude electric saw

A chainsaw and coaxial technology, applied in the direction of electric pruning saws, cutting tools, cutting equipment, etc., can solve the problems of inconvenient use of high-altitude saws, relative movement of the main rod and the telescopic rod, and inconvenient fixing of the telescopic rod.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

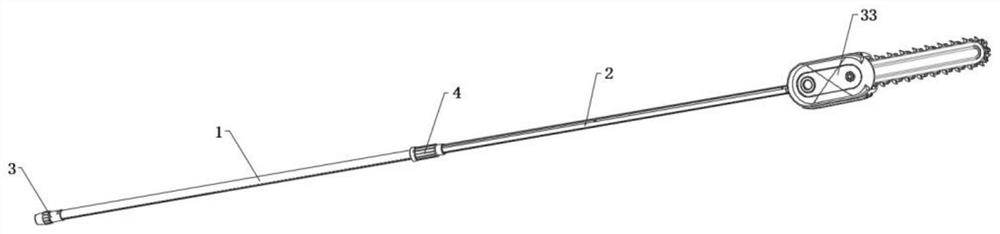

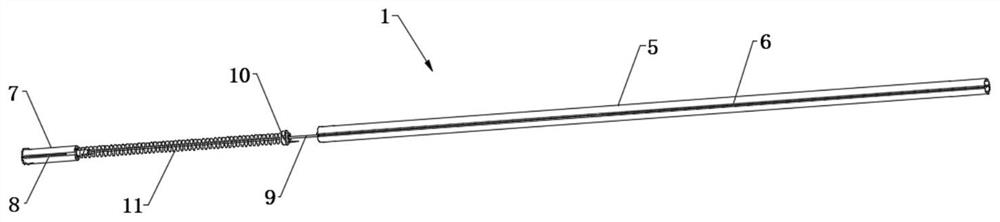

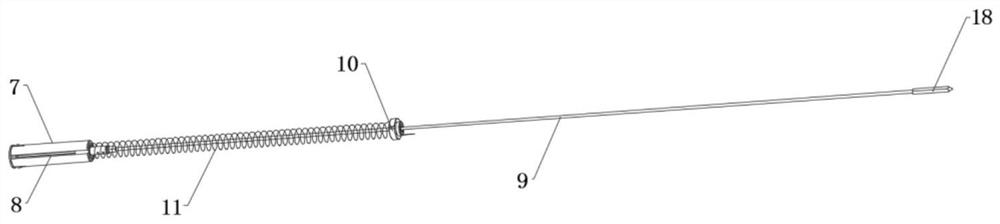

[0028] Embodiment: a kind of coaxial telescopic high-altitude chainsaw, constitutes as Figure 1-4 As shown, it includes a main rod assembly 1, a telescopic rod assembly 2, a base assembly 3 and a connecting assembly 4. The main rod assembly 1 includes a main rod 5, and both sides of the main rod 5 are symmetrically provided with first grooved rails 6. One end is symmetrically provided with two first connecting holes 12 and two second connecting holes 14, the inside of one end of the main rod 5 is provided with an inner sleeve 7, and one end of the inner sleeve 7 is symmetrically provided with two second connecting holes 14. The matching first connecting bump 13, the two sides of the inner sleeve 7 are symmetrically provided with the second groove rail 8 matched with the first groove rail 6, the above-mentioned structure is convenient for fixing the inner sleeve 7 to the end of the main rod 5 department. The end of the inner casing 7 is provided with a spring guide rod 9 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com