Gas-electric integrated ironing roller

An integrated, gas-electric technology, applied in textiles and papermaking, fabric surface trimming, etc., can solve the problem of high use cost and achieve the effect of saving equipment use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

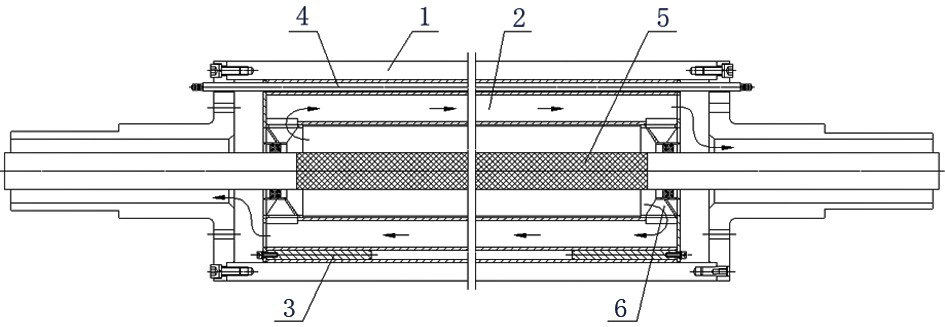

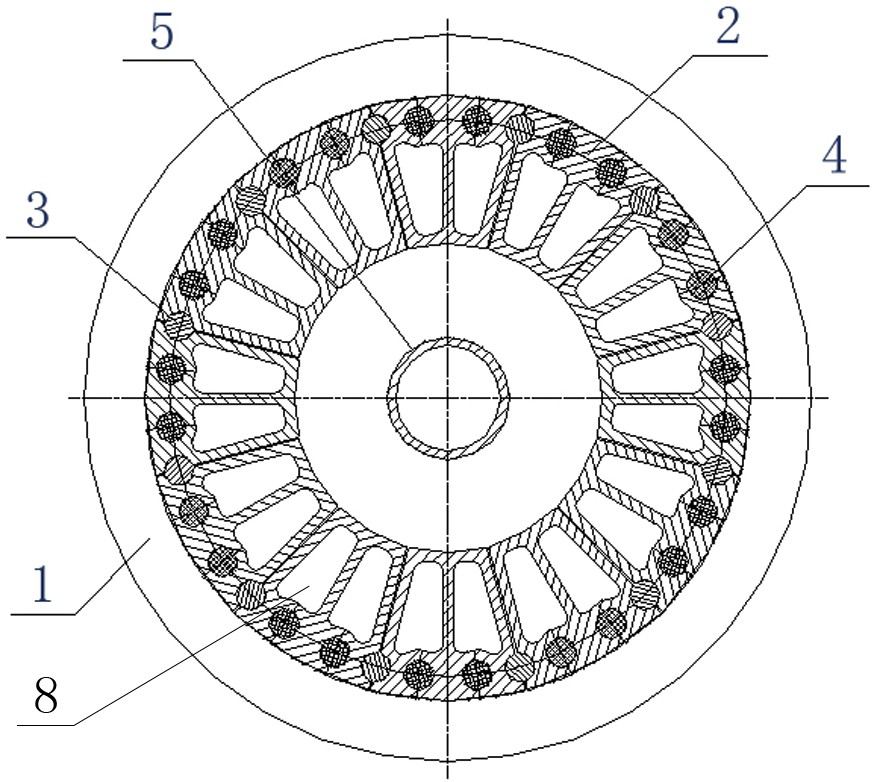

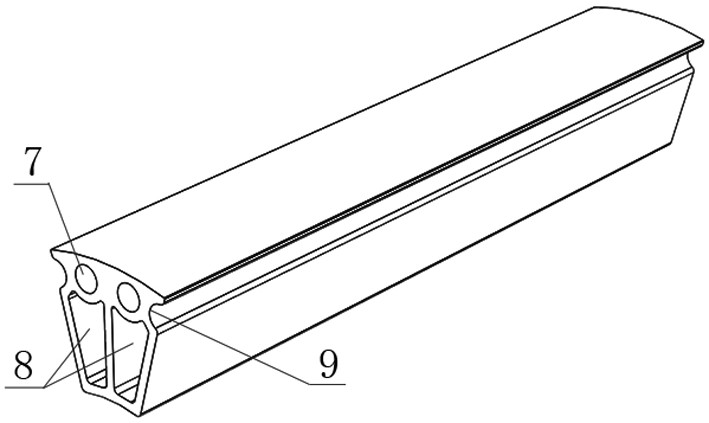

[0015] Embodiment 1: as attached figure 1 , figure 2 and image 3 As shown, a gas-electric integrated ironing roller includes an ironing roller body 1 and a shaft head, a metal surface burner 5 is provided at the center of the ironing roller body 1, and a metal surface burner 5 is provided on the inner wall of the ironing roller body 1 A circular liner composed of 12 pieces of aluminum alloy heat conduction parts 2. The aluminum alloy heat conduction parts 2 are provided with a circular cavity 7 matched with a number of electric heating tubes 4 and two for combustion exhaust gas circulation. Special-shaped hole cavity 8; semicircular positioning grooves 9 are respectively provided on both sides of the aluminum alloy heat-conducting element 2, and two adjacent aluminum alloy heat-conducting elements 2 are fixed in two adjacent semicircular positions by positioning pins 3 In the shaped positioning groove 9, it is spliced into a circular inner container. Both ends of the al...

Embodiment 2

[0016] Embodiment 2: Another air-electric integrated ironing roller, including an ironing roller body and a shaft head, the inner wall of the ironing roller is provided with a circular inner tank made of 10 pieces of aluminum alloy heat-conducting parts. Others are the same as in Example 1.

Embodiment 3

[0017] Embodiment 3: Another air-electric integrated ironing roller, including an ironing roller body and a shaft head, the inner wall of the ironing roller is provided with a circular inner container spliced by 8 pieces of aluminum alloy heat-conducting parts, so The above-mentioned aluminum alloy heat-conducting member is provided with a circular cavity matched with three electric heating tubes and a cavity with a special-shaped hole for combustion exhaust gas circulation. Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com