Nodular cast iron pipe outer surface anti-corrosion treatment technology

A technology of ductile cast iron and treatment process, which is applied in the direction of special surface, metal material coating process, device for coating liquid on the surface, etc., can solve the problems of easily regenerating rust and affecting the anti-corrosion effect, and achieve improved effect and efficiency , personal safety protection, and the effect of improving operational efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

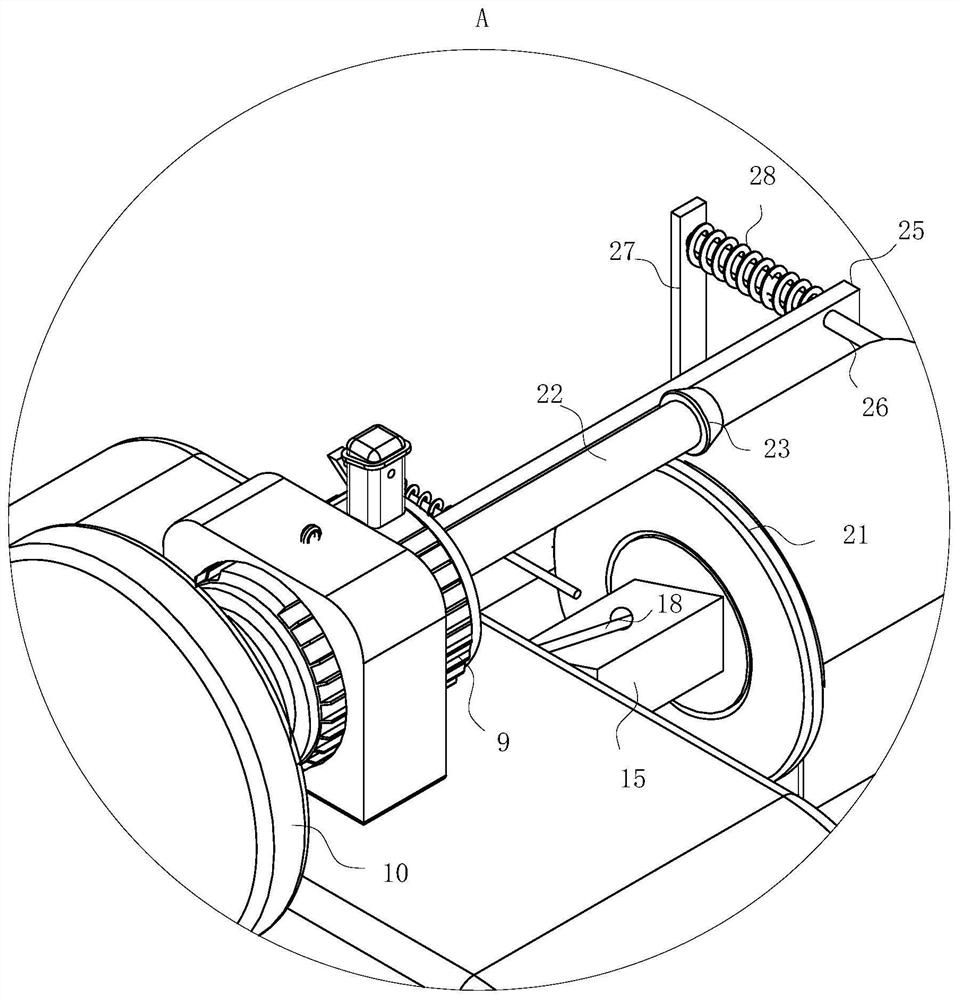

[0037] As a specific embodiment of the present invention, the side of the rectangular plate 5 away from the push rod motor 3 is provided with a fixed blade 24 and a mounting plate 25, and the side wall of the mounting plate 25 is provided with two limiting holes for limiting A round bar 26 is movably installed at the bit hole, and the end of the round bar 26 away from the fixed blade 24 is fixed with a limiting plate 27, and a back-moving spring 28 is arranged between the limiting plate 27 and the mounting plate 25, and the back-moving spring 28 Winding is arranged on the surface of the round rod 26, and the bottom end of the limit plate 27 is fixed with a movable blade 29; when in use, the round rod 26 is squeezed while the bracket 15 is turned upward, so that the movable blade 29 is squeezed away from the fixed blade. The direction of the blade 24; when the cast iron pipe completes all winding, it is separated from the runner 20, so that the bracket 15 rotates downward, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com