Crane anti-swing control system capable of improving loading and unloading stability

A control system and crane technology, applied in transportation and packaging, load hanging components, etc., can solve problems such as affecting production efficiency, trolley speed adjustment, driver discomfort, etc., to achieve good use flexibility, avoid life, and shorten parking distance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

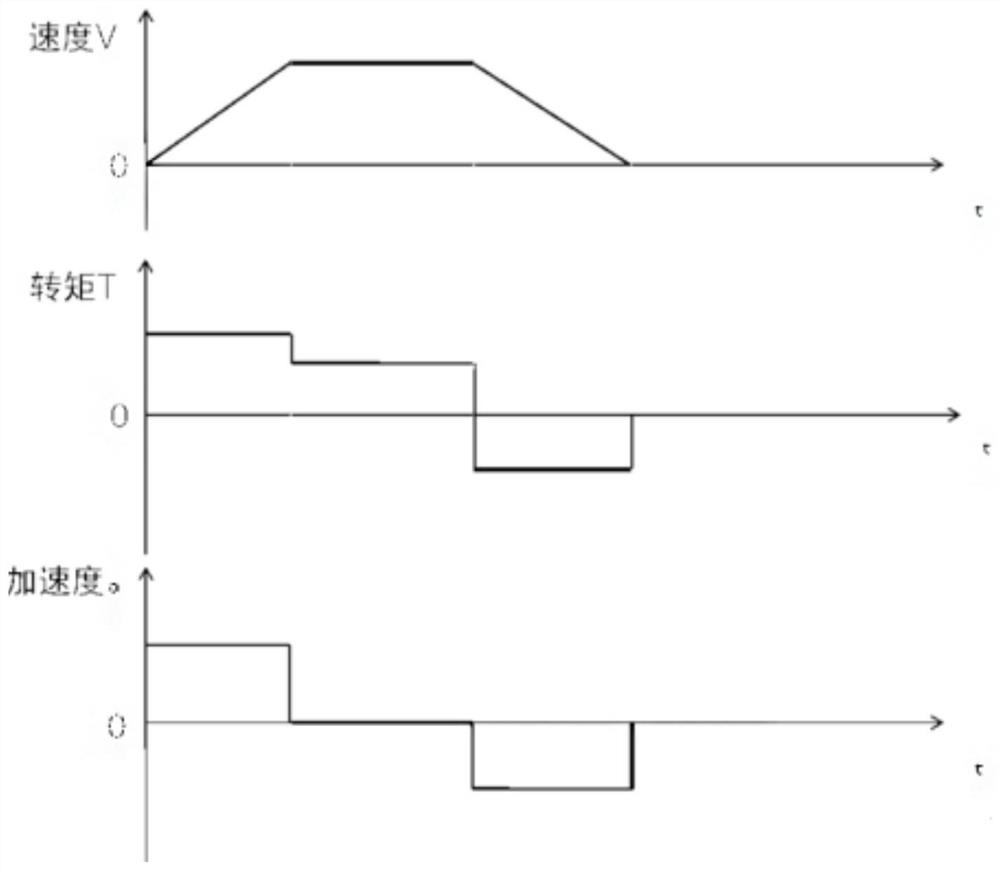

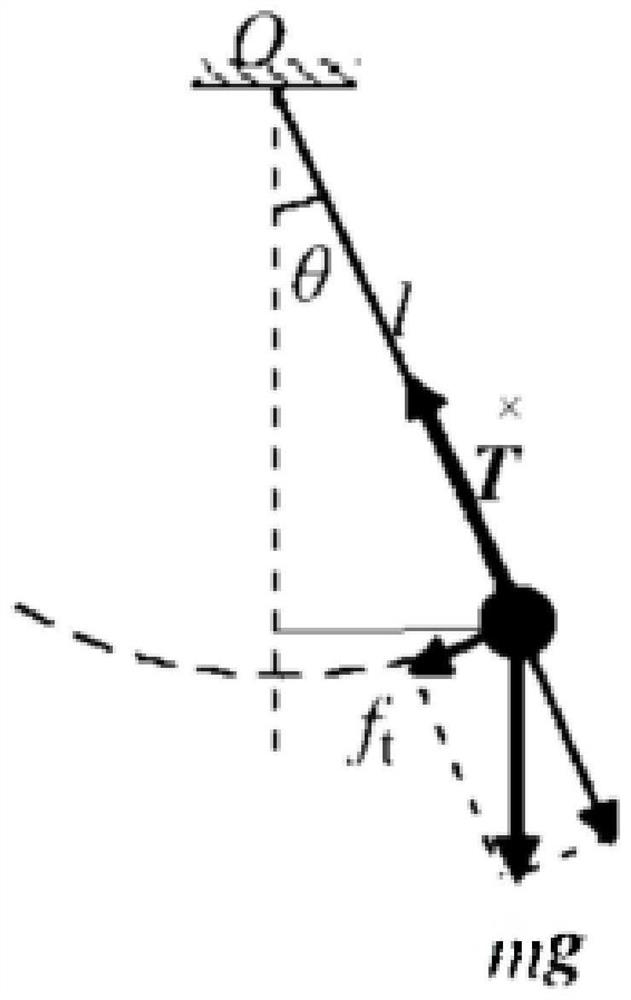

[0025] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-2 As shown, a crane anti-sway control system that improves the stability of loading and unloading. The system hardware is mainly composed of programmable controllers, frequency converters for each mechanism, and hoisting encoders. The EtherNet / IP communication protocol is used for networking between each part. , by obtaining the operating parameters of the hoisting, large and small trolley mechanisms of the bridge crane; according to the actual height of the load and the operating parameters of the large and small trolleys, adjust the output frequency of the inverter in real time when the operating mechanism starts and stops to change the operating state; according to the calculated load The swing parameter adjusts the speed curve of the operating mechanism in real time to minimize the adverse effect of anti-sway on the increase of the sliding distance when the cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com