Preparation method of foam concrete based on plant-based foaming agent

A foam concrete and plant-based technology, applied in ceramic products, applications, household appliances, etc., can solve the problems of poor thermal insulation performance and compressive strength, limitations, etc., and achieve excellent thermal insulation capability, excellent quality, and good impermeability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

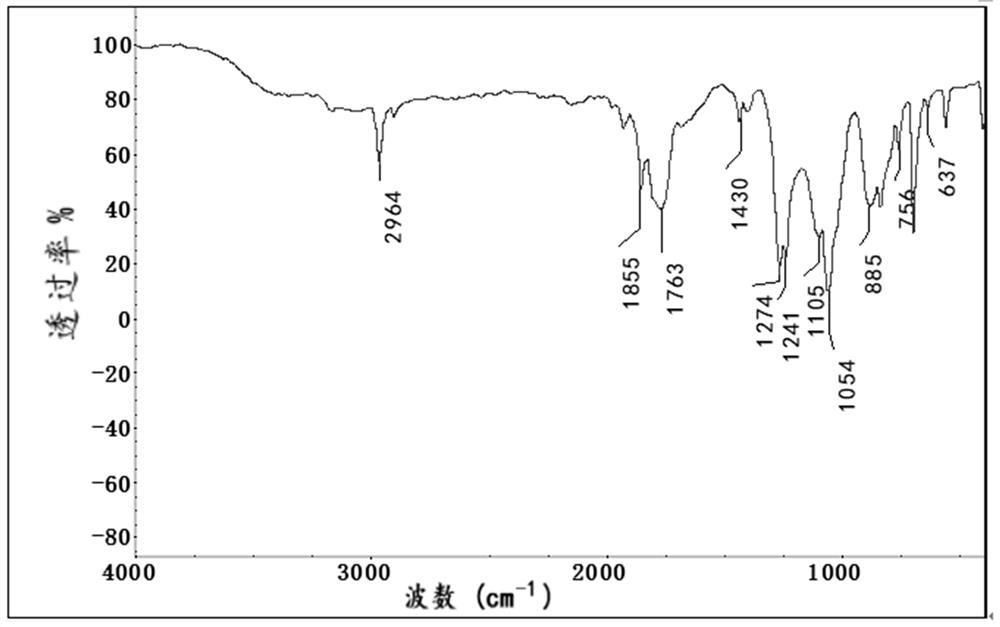

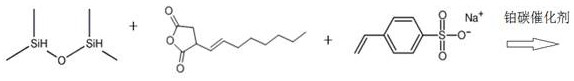

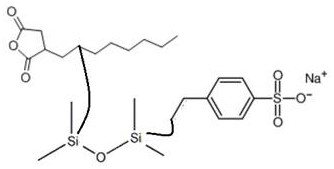

Image

Examples

Embodiment 1

[0026] A method for preparing foamed concrete based on a plant-based foaming agent, the main scheme of which is as follows:

[0027] Add 80kg of cement, 40kg of river sand, 5kg of zeolite powder and 50kg of fly ash into the mixer, mix and dry mix for 20 minutes, then pour 0.1kg of water reducing agent, 6kg of modified diatomite and 10kg of slag into it and mix evenly Obtain the mixture; then add 2kg of plant-based protein foaming agent to 80kg of water and stir evenly, continue to stir for 10min to obtain a mixed solution, then pour it into the dry material and mix evenly, and stir it with a high-speed mixer to make a foamed concrete slurry, and stir The time is 2 minutes, and then the concrete is poured into the mold, and after standing for 24 hours, the mold is demoulded and cured, and the foamed concrete product is obtained.

[0028] The preparation method of the modified diatomite is as follows: add 20kg of diatomite raw soil to 100kg of sulfuric acid with a concentration ...

Embodiment 2

[0037] A method for preparing foamed concrete based on a plant-based foaming agent, the main scheme of which is as follows:

[0038] Add 100kg of cement, 50kg of river sand, 8kg of zeolite powder and 60kg of fly ash into the mixer, mix and dry mix for 25 minutes, then pour 0.3kg of water reducing agent, 8kg of modified diatomite, and 13kg of slag into it and mix evenly Obtain the mixture; then add 4kg of plant-based protein foaming agent to 100kg of water and stir evenly, continue to stir for 15min to obtain a mixed solution, then pour it into the dry material and mix evenly, and stir with a high-speed mixer to make a foamed concrete slurry, and stir The time is 5 minutes, and then the concrete is poured into the mold, and after standing for 36 hours, the mold is demoulded and cured, and the foamed concrete product is obtained.

[0039] The preparation method of the modified diatomite is as follows: add 31kg of diatomite raw soil to 150kg of sulfuric acid with a concentration ...

Embodiment 3

[0048] A method for preparing foamed concrete based on a plant-based foaming agent, the main scheme of which is as follows:

[0049] Add 120kg of cement, 60kg of river sand, 10kg of zeolite powder and 70kg of fly ash into the mixer, mix and dry mix for 30 minutes, then pour 0.5kg of water reducing agent, 12kg of modified diatomite, and 15kg of slag into it and mix evenly Obtain the mixture; then add 7kg of plant-based protein foaming agent to 120kg of water and stir evenly, continue to stir for 20min to obtain a mixed solution, then pour it into the dry material and mix evenly, and stir it with a high-speed mixer to make a foamed concrete slurry, and stir The time is 7 minutes, and then the concrete is poured into the mold, and after standing for 24-48 hours, the mold is demoulded and cured, and the foamed concrete product is obtained.

[0050] The preparation method of the modified diatomite is as follows: add 35kg of diatomite raw soil to 180kg of sulfuric acid with a mass p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com