Heat treatment processing device for plastic films

A technology of plastic film and processing device, which is applied in the field of plastic film production, can solve the problems of lack of heat treatment production and processing lines, and achieve the effect of smooth conveying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

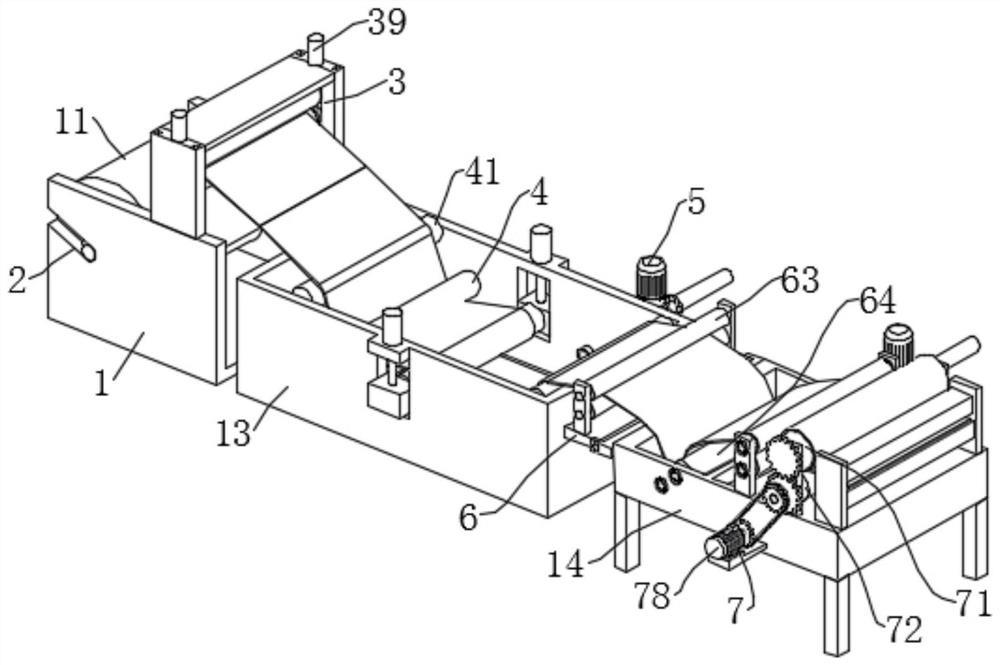

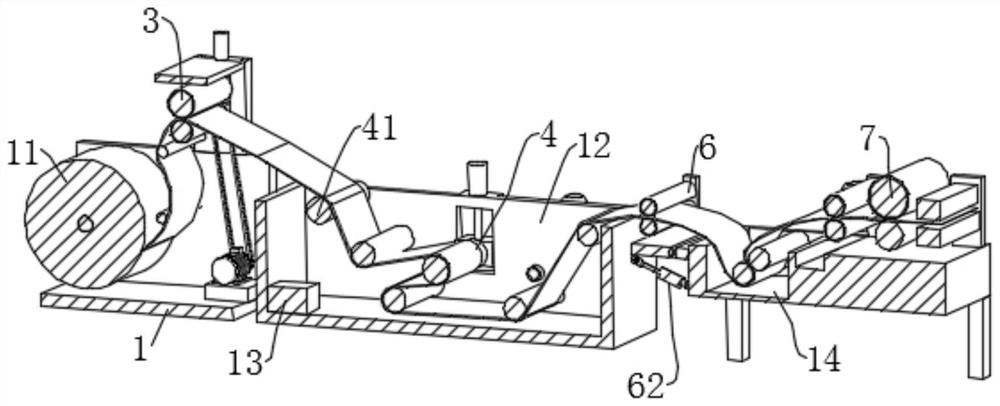

[0048] refer to figure 1 and figure 2 , a double-layer plastic film 13 processing device mainly includes the following parts:

[0049] Includes rack 1, also includes:

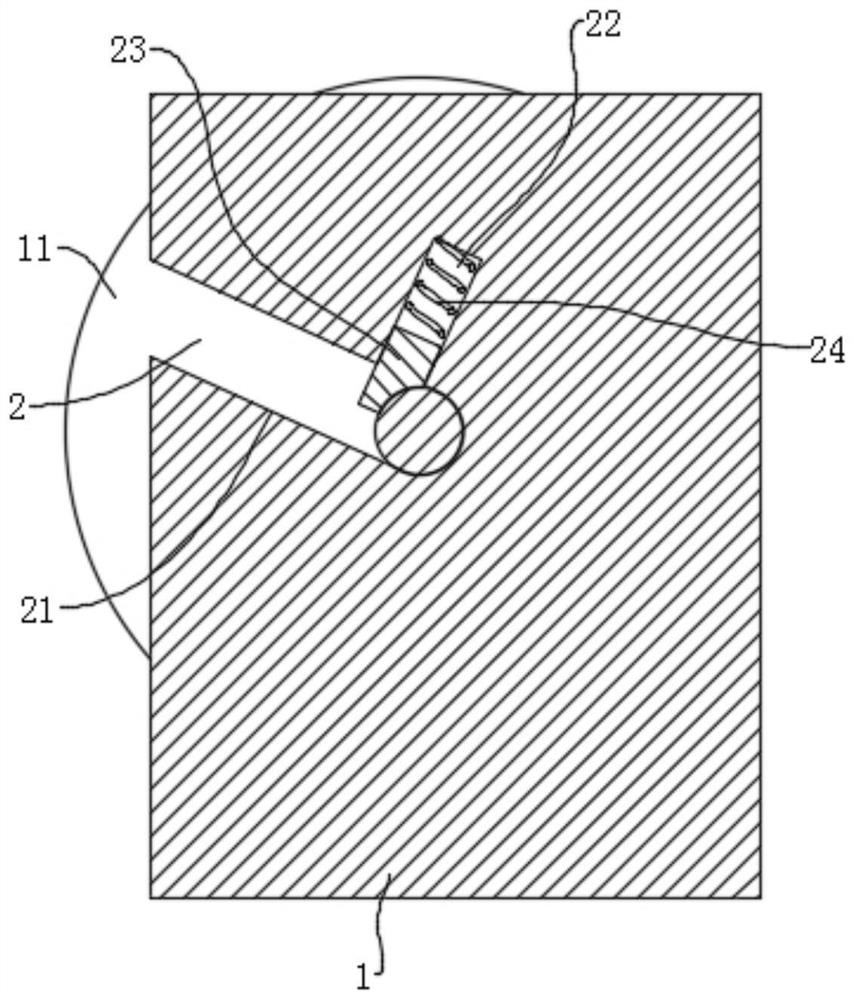

[0050] Two groups of quick release mechanisms 2 for conveniently replacing the discharge roller 11 coiled with plastic film;

[0051] An uncoiling mechanism 3 for unwinding the plastic film in the discharge roller 11;

[0052] A heat treatment box 12 fixed on the frame 1, a temperature-controlled heater 13 is arranged in the heat treatment box 12;

[0053] The tension transmission assembly 4 for tensioning and transmitting the plastic film arranged in the heat treatment box 12;

[0054] A cleaning box 14 fixed on the frame 1;

[0055] A supply mechanism 5 for supplying heat treatment liquid into the heat treatment tank 12 and a supply mechanism 5 for supplying cleaning liquid into the cleaning tank 14;

[0056] The stability maintenance mechanism 6 for keeping the plastic film transmission in the cleanin...

Embodiment 2

[0066] refer to figure 1 and figure 2 , a double-layer plastic film 13 processing device mainly includes the following parts:

[0067] Includes rack 1, also includes:

[0068] Two groups of quick release mechanisms 2 for conveniently replacing the discharge roller 11 coiled with plastic film;

[0069] An uncoiling mechanism 3 for unwinding the plastic film in the discharge roller 11;

[0070] A heat treatment box 12 fixed on the frame 1, a temperature-controlled heater 13 is arranged in the heat treatment box 12;

[0071] The tension transmission assembly 4 for tensioning and transmitting the plastic film arranged in the heat treatment box 12;

[0072] A cleaning box 14 fixed on the frame 1;

[0073] A supply mechanism 5 for supplying heat treatment liquid into the heat treatment tank 12 and a supply mechanism 5 for supplying cleaning liquid into the cleaning tank 14;

[0074] The stability maintenance mechanism 6 for keeping the plastic film transmission in the cleanin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com