70MPa-resistant standard hydrophone and manufacturing method thereof

A hydrophone, a standard technology, applied in instruments, measuring devices, measuring ultrasonic/sonic/infrasonic waves, etc., to achieve the effects of improving pressure bearing capacity, increasing bonding area, and improving pressure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

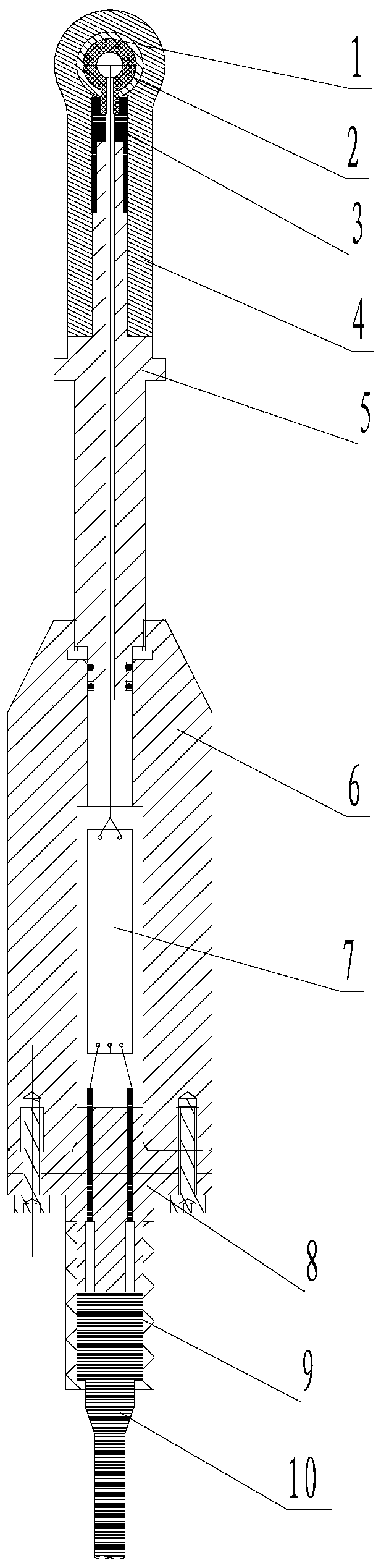

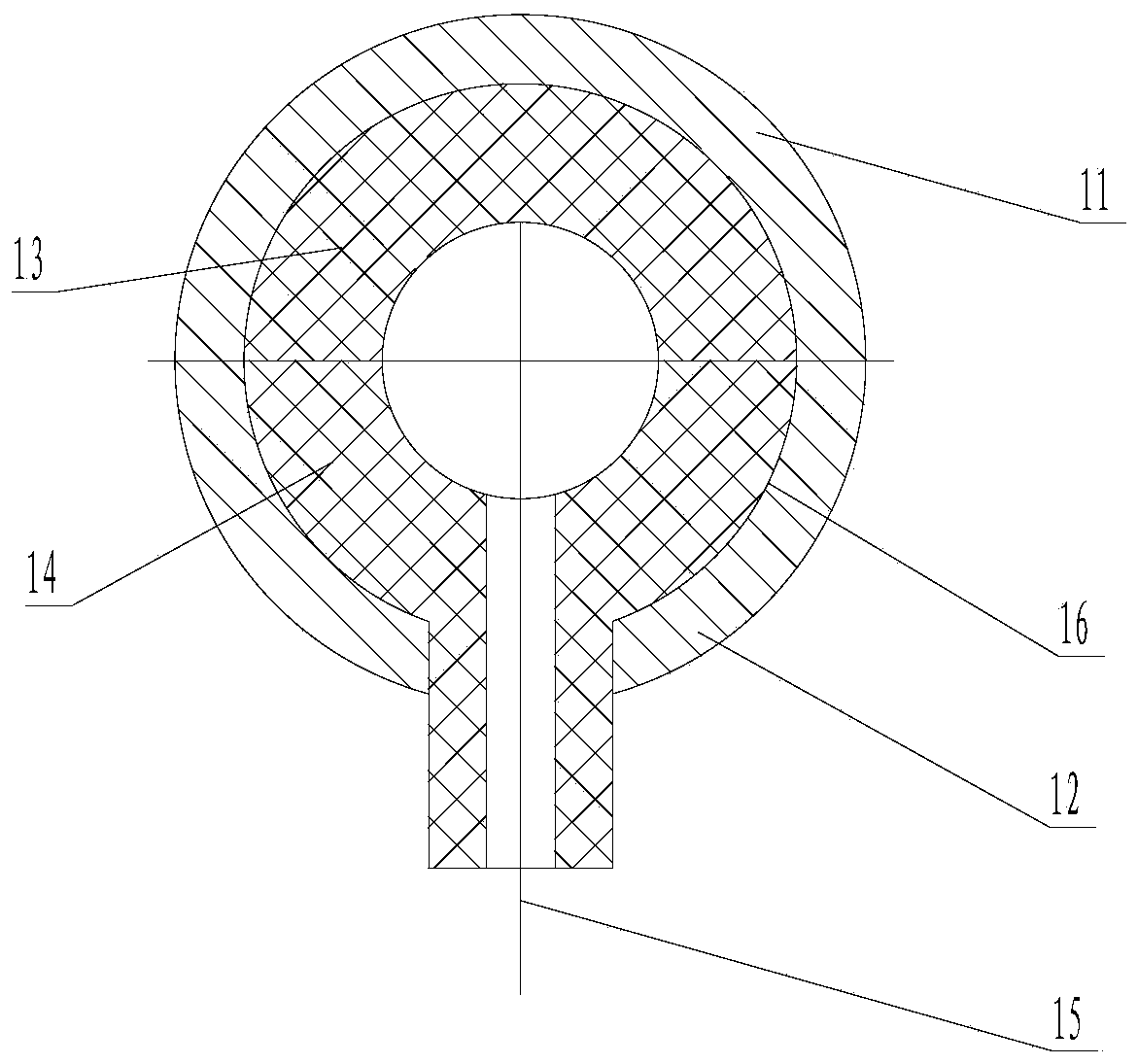

[0029] Example: as attached figure 1 As shown, this 70MPa-resistant standard hydrophone mainly includes a piezoelectric ceramic spherical shell 1, a high-strength composite foam 2, a support structure 5, a high-voltage resistant connector 8 and a high-voltage resistant watertight cable 10, and the piezoelectric ceramic ball The shell 1 is formed by bonding two hollow hemispheres, and a high-strength composite foam 2 is placed inside it. The high-strength composite foam 2 is composed of two hollow hemispherical structures. The inner wall of 1 is tightly connected; the lower half of the piezoelectric ceramic spherical shell 1 extends downward to open a small hole for the wire to be connected, and is connected to the support structure 5 through the rubber decoupling part 3, and is coated on the outer circumference of the piezoelectric ceramic spherical shell 1. There is a waterproof and sound-permeable layer 4; a through hole is provided inside the support structure 5 for the pas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com