Plywood support structure for adjacent ore removal tunnels and construction process thereof

A technology of supporting structure and roadway, applied in tunnels, tunnel linings, mining equipment, etc., can solve the problems of loss of supporting effect, poor stability, shrinkage of surrounding rock between columns, etc., to achieve safe and orderly production, reduce Maintenance cost, effect of enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

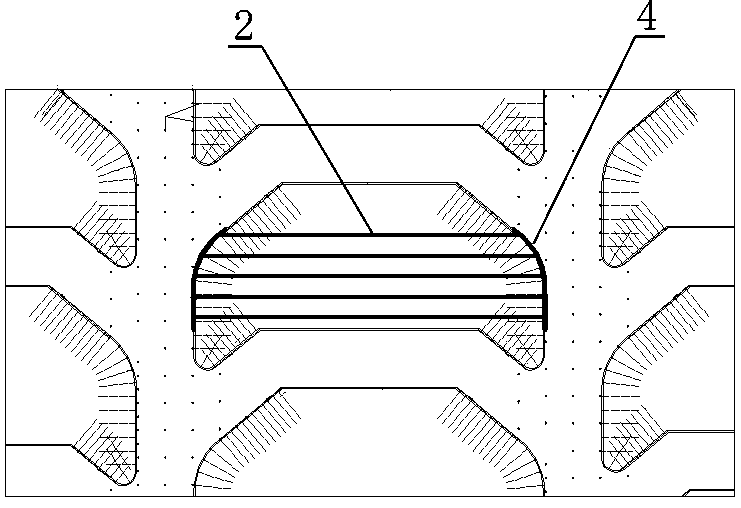

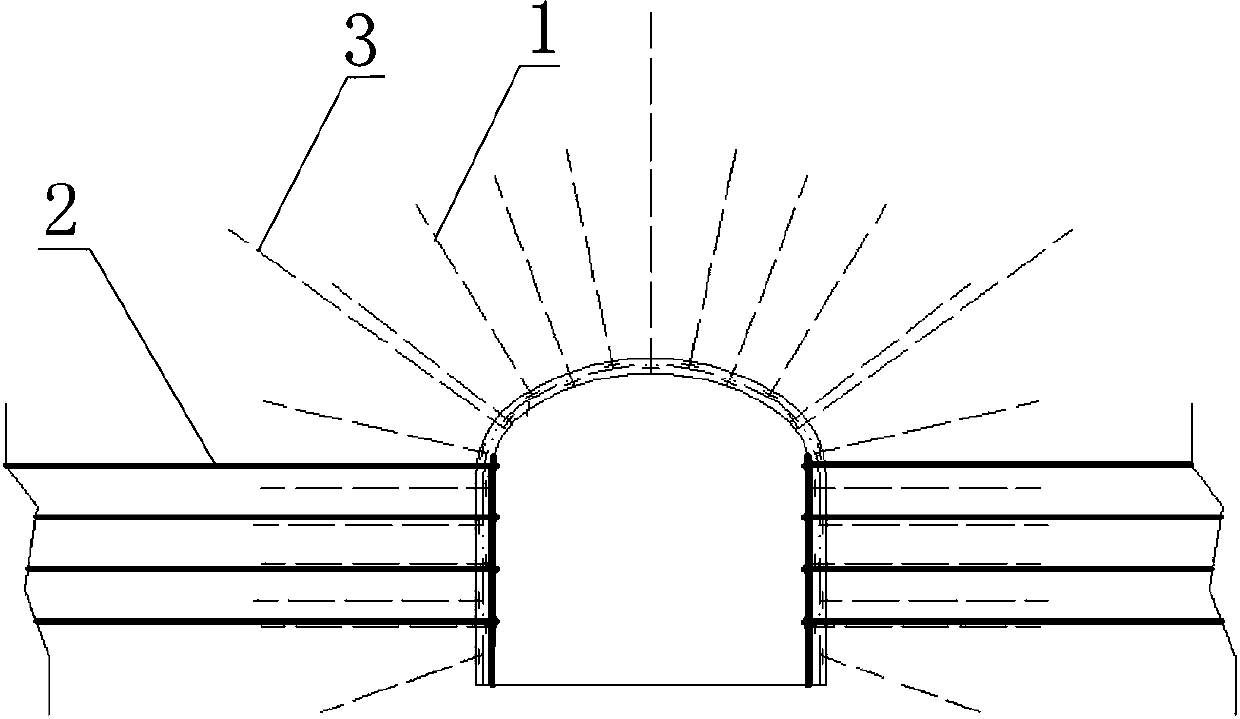

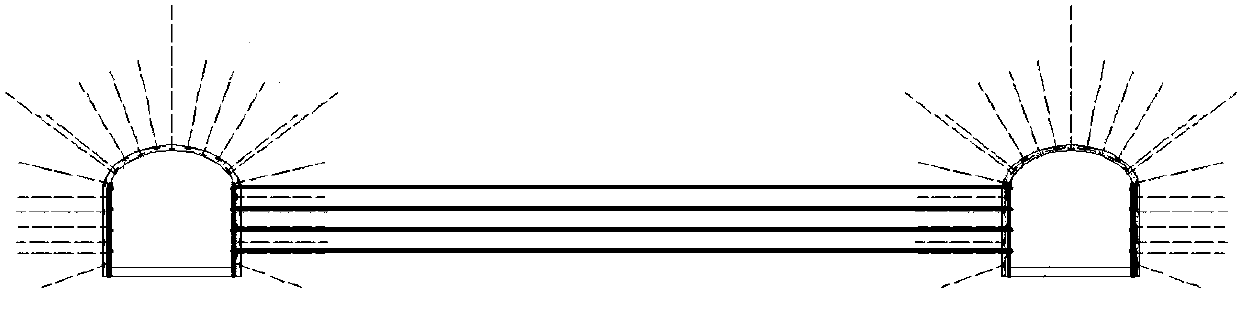

[0038] Embodiment 1: A splint support structure for an adjacent mining roadway, including a bolt hole, a mortar bolt 1, a horizontal anchor cable 2, a top anchor cable 3, a concrete protective layer and a supporting plate 4, and the anchor hole is set at the outlet In the surrounding rock at the top of the mine roadway, the mortar bolt 1 is inserted into the bolt hole, and the gap between the mortar bolt 1 and the bolt hole is filled with mortar; Concrete coating with a strength grade of C25; the supporting plate 4 is a steel plate, which is closely fixed on the concrete protective structure, and several anchor cable holes are arranged in parallel in the surrounding rock between two adjacent mining roadways. A 30-meter-long horizontal anchor cable 2 is provided, and mortar is filled between the horizontal anchor cable 2 and the anchor cable hole, and the two ends of the horizontal anchor cable 2 are fixedly connected with the supporting plates 4 on both sides of the surrounding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com