Si-based GaN epitaxial low-dislocation film and preparation method thereof

A low-dislocation and epitaxy technology, applied in the field of microelectronics, which can solve problems such as cracks, stacking faults, and thin-film dislocations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

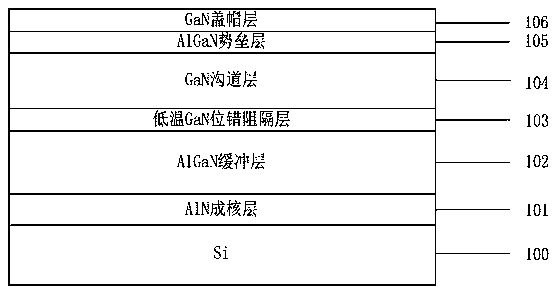

[0027] Growth in MOCVD system by metal organic chemical vapor deposition:

[0028] 1. First put the Si substrate into the reaction chamber and raise the temperature to 1100°C, and remove the oxide film on the surface under H2 conditions;

[0029] 2. On the basis of the above steps, the temperature is lowered to 1000° C., and a layer of ALN nucleation layer is grown with a thickness of 100 nm. The film thickness is realized by controlling the deposition time and cooperating with MOCVD monitoring system.

[0030] 3. Based on the above steps, the temperature is raised to 1100° C., and an ALGaN buffer layer is grown with a thickness of 1 μm.

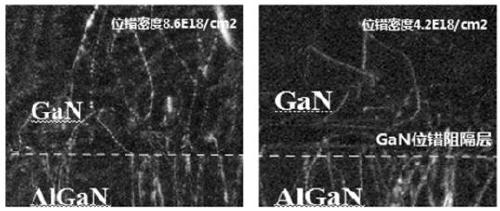

[0031] 4. On the basis of the previous steps, the temperature was lowered to 800° C., and a dislocation barrier layer with a thickness of 200 nm was grown.

[0032] 5. On the basis of the above steps, the temperature is raised to 1100° C., and the GaN channel layer, AlGaN barrier layer and GaN cap layer are grown, with thicknesses of 2um, ...

Embodiment 2

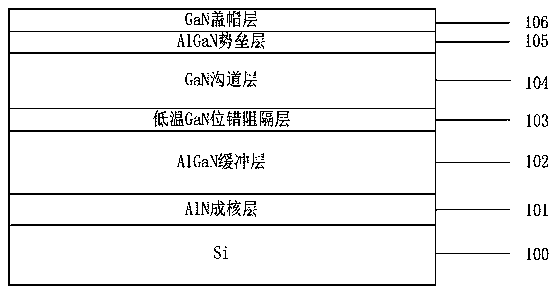

[0034] Growth in MOCVD system by metal organic chemical vapor deposition:

[0035] 1. First put the Si substrate into the reaction chamber and raise the temperature to 1100°C, and remove the oxide film on the surface under H2 conditions;

[0036] 2. On the basis of the above steps, the temperature is lowered to 1000° C., and a layer of ALN nucleation layer is grown with a thickness of 100 nm. The film thickness is realized by controlling the deposition time and cooperating with MOCVD monitoring system.

[0037] 3. Based on the above steps, the temperature is raised to 1100° C., and an ALGaN buffer layer is grown with a thickness of 1 μm.

[0038] 4. On the basis of the above steps, the temperature is lowered to 800° C., and a dislocation barrier layer with a thickness of 300 nm is grown.

[0039] 5. On the basis of the above steps, the temperature is raised to 1100° C., and the GaN channel layer, AlGaN barrier layer and GaN cap layer are grown, with thicknesses of 2um, 30nm,...

Embodiment 3

[0041] Growth in MOCVD system by metal organic chemical vapor deposition:

[0042] 1. First put the Si substrate into the reaction chamber and raise the temperature to 1100°C, and remove the oxide film on the surface under H2 conditions;

[0043] 2. On the basis of the above steps, the temperature is lowered to 1000° C., and a layer of ALN nucleation layer is grown with a thickness of 100 nm. The film thickness is realized by controlling the deposition time and cooperating with MOCVD monitoring system.

[0044] 3. Based on the above steps, the temperature is raised to 1100° C., and an ALGaN buffer layer is grown with a thickness of 1 μm.

[0045] 4. On the basis of the above steps, the temperature is lowered to 800° C., and a dislocation barrier layer with a thickness of 400 nm is grown.

[0046] 5. On the basis of the above steps, the temperature is raised to 1100° C., and the GaN channel layer, AlGaN barrier layer and GaN cap layer are grown, with thicknesses of 2um, 30nm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com