A Rotary Adjustable Cup Metering Mechanism

A technology of rotary type and metering disc is applied in the field of rotary adjustable volume cup measurement mechanism, which can solve problems such as poor measurement accuracy, and achieve the effects of improving efficiency, improving measurement efficiency and convenient adjustment process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

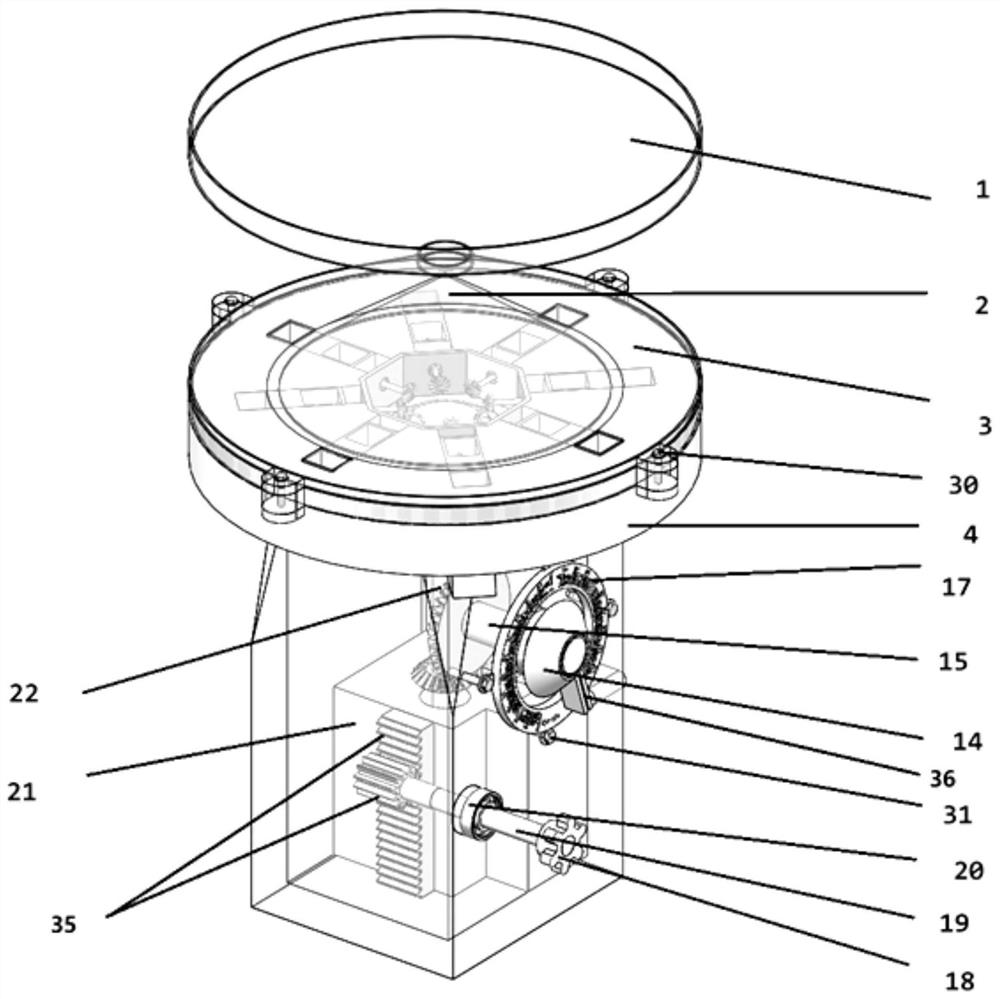

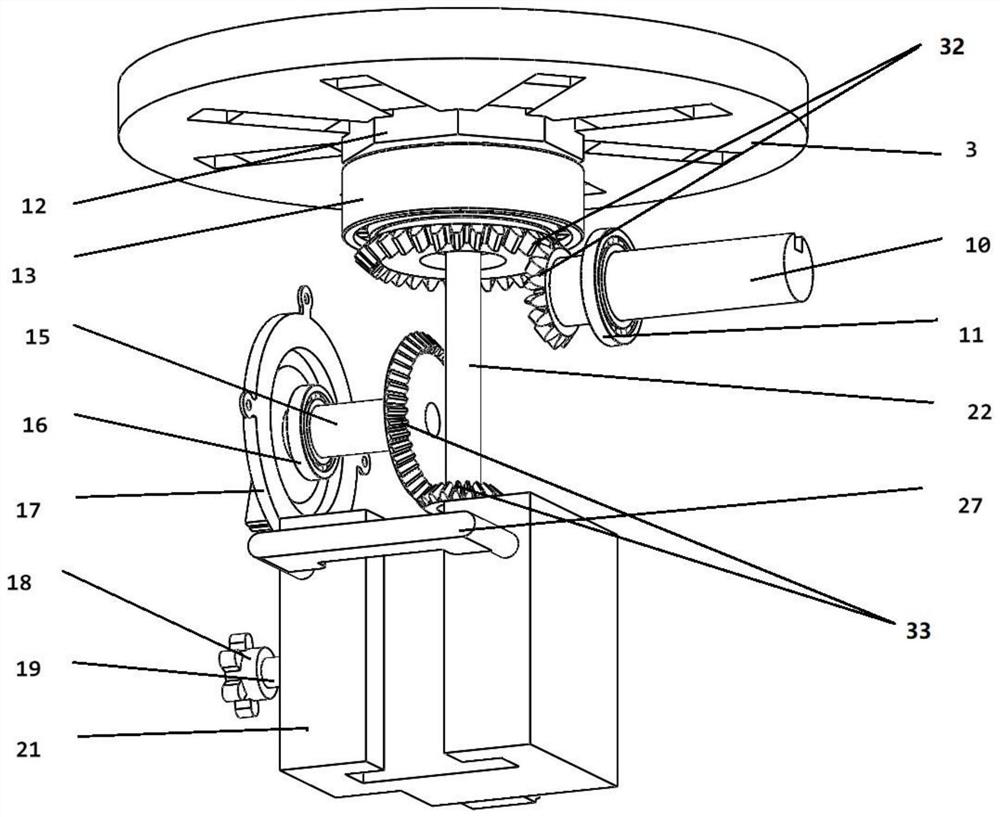

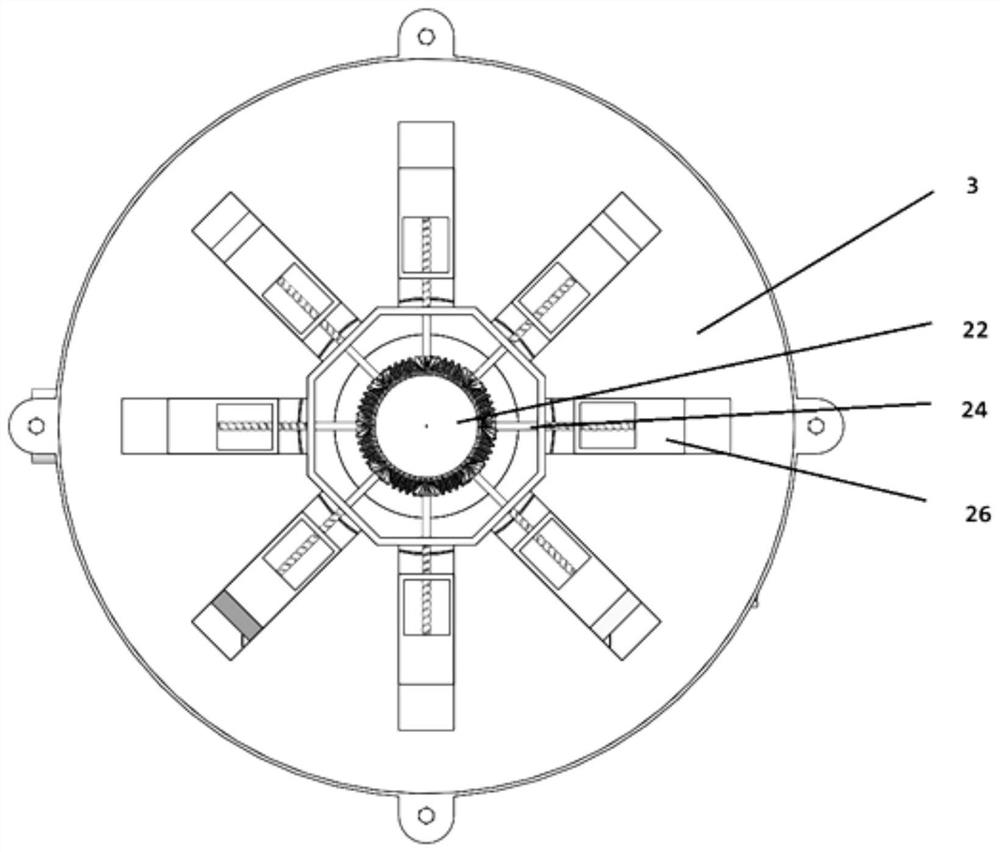

[0035] See Figure 1 - Figure 5 This embodiment proposes a rotary adjustable cup metering mechanism, including an outer case body 28, and a discharge disk 4, an intermediate meter 3, a feed disc 2, and a mid-meter disk 3, a feed disc 2, and a discharge plate, an intermediate meter 3, a feed plate 2, and a discharge plate, a discharge plate, which are arranged in the outer casing 28, and from the bottom-. The feed bucket 1, wherein the discharge pan 4 is fixed to the outer casing 28, and the intermediate metering disc 3 is provided with a plurality of volumes that can be adjusted and the upper and lower end surface openings, the feed tray 2 and the discharge pan 4 are respectively provided. The feed port and discharge port 5, wherein the top and bottom ends of the feed port are respectively against the feed tip 1 and the intermediate meter 3, and when the feed port is being metering the chamber, another metering cavity The chamber is positively to the discharge port 5, and the inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com