An annular inspection driving mechanism outside a material cabin and an annular inspection mechanism

A driving mechanism, outer ring technology, applied in the direction of analyzing materials, motor vehicles, instruments, etc., can solve the problem of real-time monitoring of surface topography of materials that cannot be exposed, save weight and space resources, light weight, avoid transmission stuck or Ineffective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

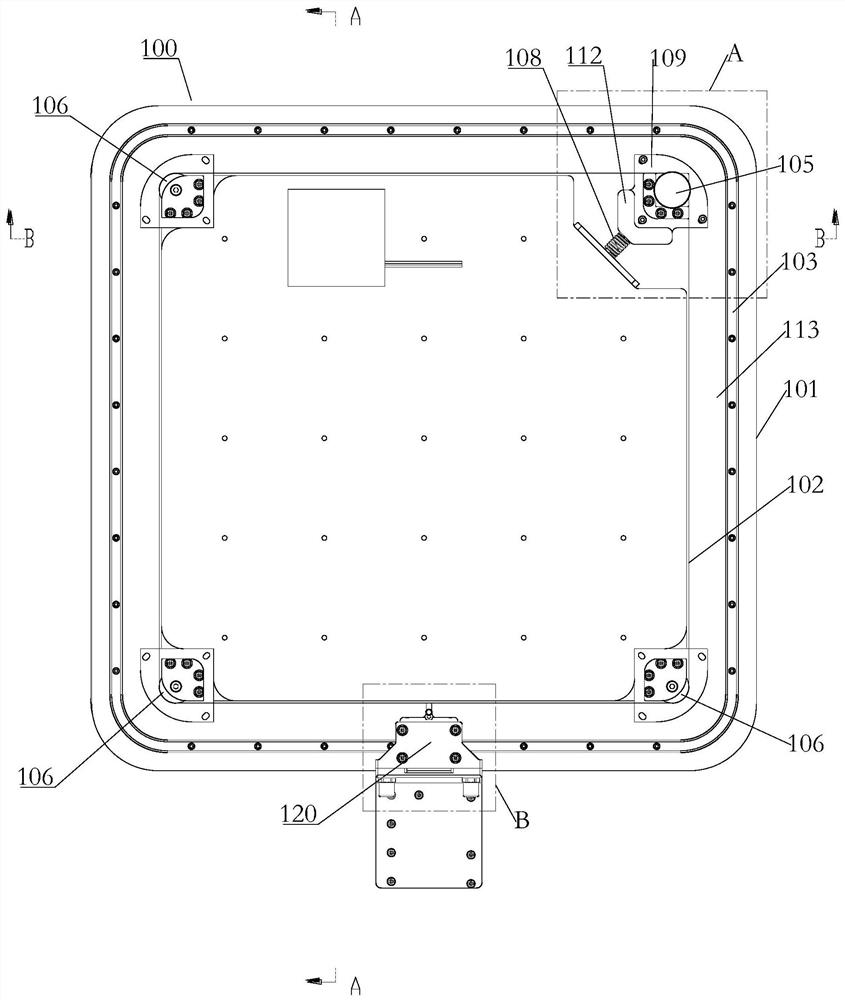

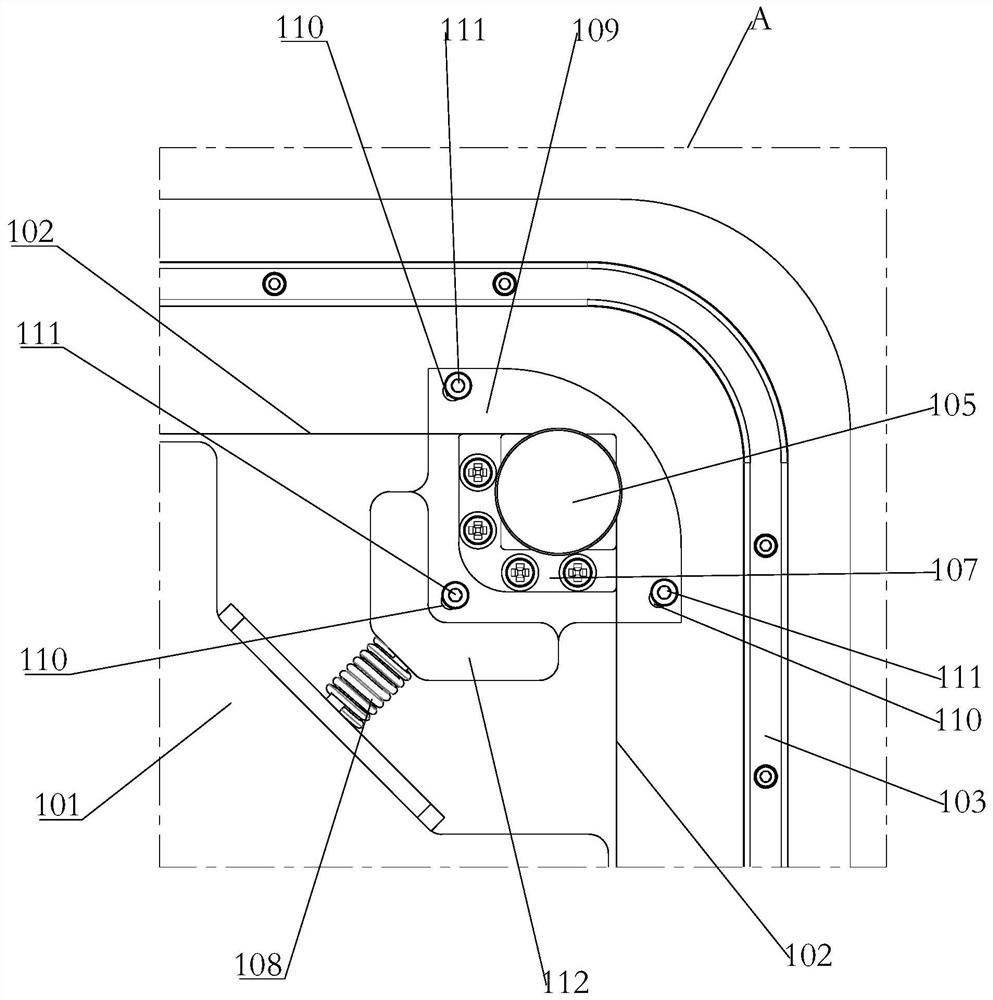

[0070] Such as Figure 1-Figure 5 As shown, a kind of circular inspection driving mechanism outside the material cabin of the present embodiment includes:

[0071] An installation platform 101 is provided with a steel belt driving mechanism;

[0072] An endless steel belt 102, which is arranged around the installation platform 101 and moves in a circular motion around the installation platform 101 under the drive of the steel belt driving mechanism;

[0073] The ring guide rail 103 is arranged around the installation platform 101 and is located on the outer peripheral side of the ring steel belt 102; the ring guide rail provides bearing and guidance for the ring inspection device, and is composed of two types of straight section guide rail and curved section guide rail The guide rail of the curved section is mainly matched with the corner of the installation platform to realize the circular motion of the circular inspection device;

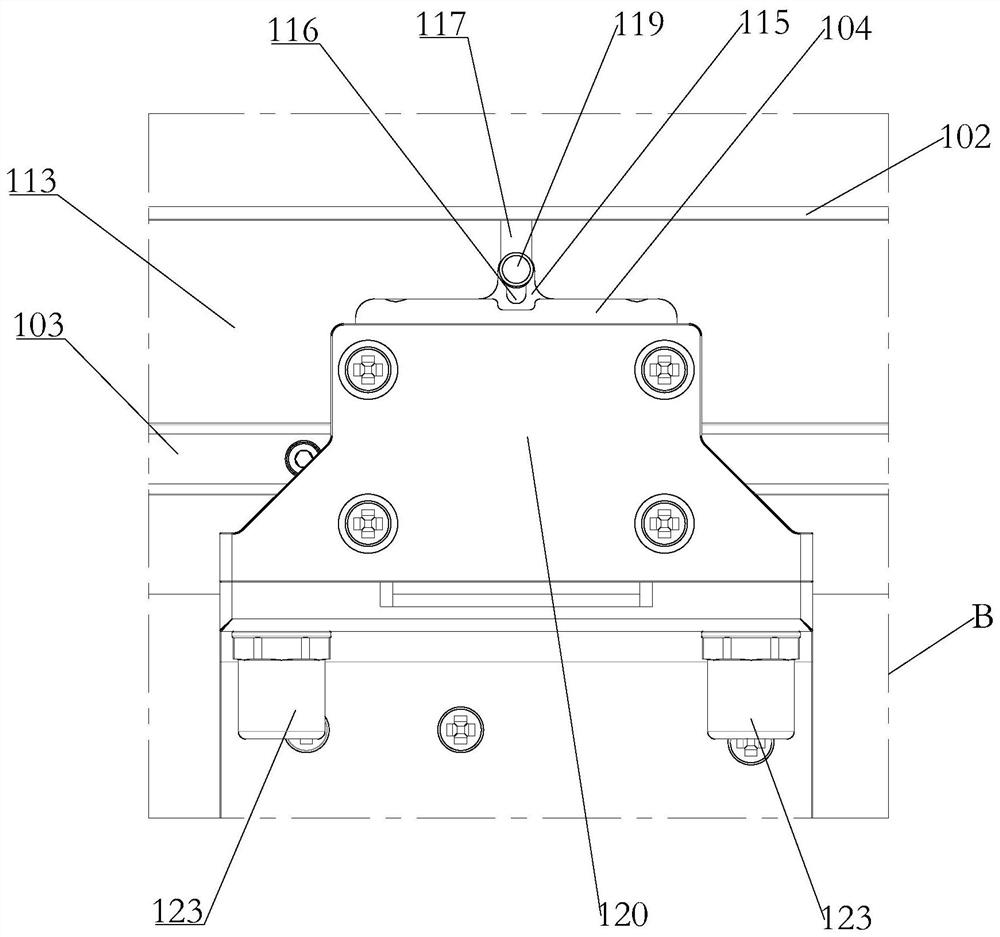

[0074] The bearing slider 104 for carryin...

Embodiment 2

[0097] Such as Figure 6-Figure 9 As shown, a circular inspection mechanism outside the cabin of materials in this embodiment includes the circular inspection drive mechanism 100 and a circular inspection device, and the annular inspection device includes a mounting bracket 301 and a vertical drive mechanism. The installation bracket 301 is installed on the bearing slider 104, and the optical inspection module 200 is installed on the vertical driving mechanism and moves up and down under the driving of the vertical driving mechanism; the vertical driving mechanism is a vertical steel Belt drive mechanism 300 .

[0098] Among them, such as Figure 6-Figure 9 As shown, the vertical steel belt drive mechanism 300 includes a vertical steel belt drive motor 302, a steel belt pulley one, a steel belt pulley two, a steel belt pulley bracket one 303, a steel belt pulley bracket two 304 and a vertical drive steel belt 306, The mounting bracket 301 is vertically arranged and the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com