Differential control system and method for molten iron car and computer readable storage medium

A technology of a control system and a control method is applied in the field of differential speed control systems of hot metal vehicles and computer-readable storage media, and can solve the problems of difficulty in controlling the differential speed of single-axis and multi-axis driving wheels of hot metal vehicles, so as to improve the control accuracy and The effect of stability, improving the level of intelligence, and accurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

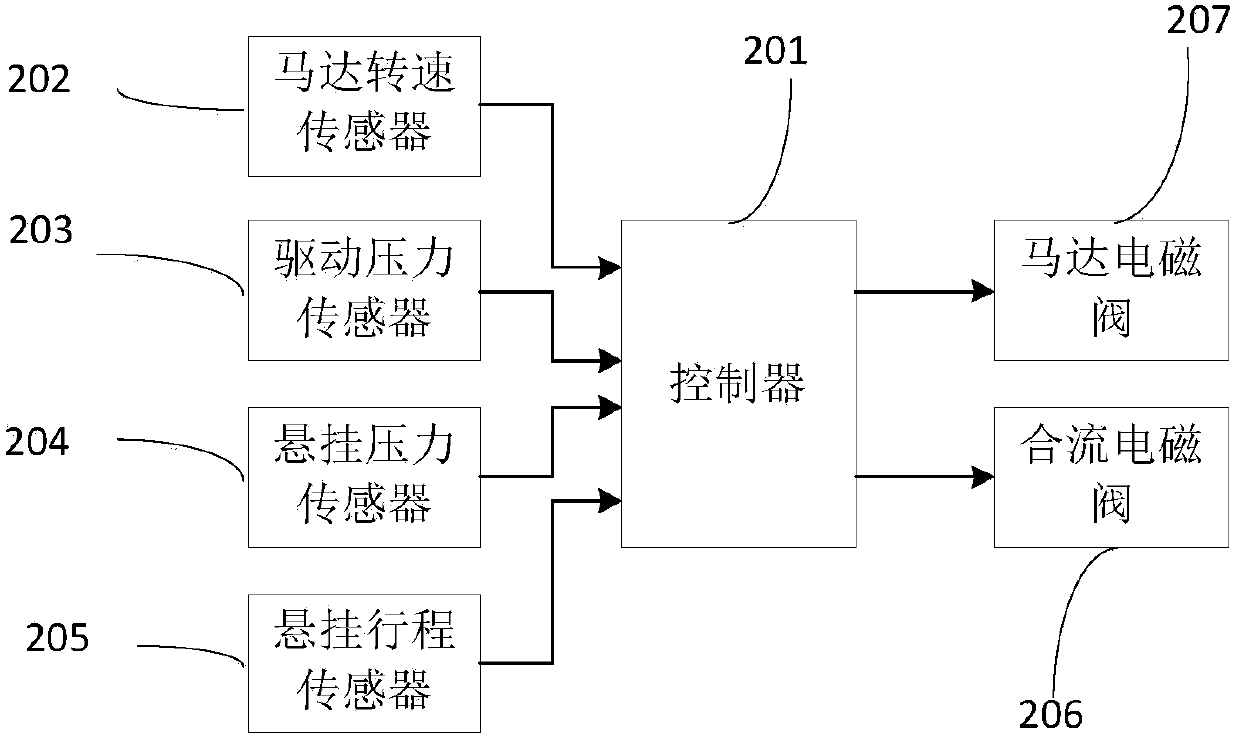

[0059] see figure 2 , the present invention provides a differential speed control system for a molten iron car. The molten iron car includes multiple sets of drive wheels, each set of drive wheels includes a drive motor, and the control system includes:

[0060] A plurality of motor speed sensors 202 are respectively connected to a driving motor for detecting the current speed of the driving motor;

[0061] A plurality of driving pressure sensors 203 are respectively connected to a driving motor for detecting the magnitude of the driving pressure;

[0062] A plurality of suspension pressure sensors 204 are respectively connected to a suspension cylinder for detecting the pressure in the suspension cylinder;

[0063] A plurality of suspension stroke encoders 205 are respectively connected to a suspension cylinder for detecting the elongation of the piston rod of the suspension cylinder;

[0064] The controller 201 is used for judging the state of the driving wheel according ...

Embodiment 2

[0068] The present invention also provides a control method of the differential speed control system of the molten iron car, the control method comprising:

[0069] Obtain the rotational speed value of the rotational speed of the current drive motor detected by the motor rotational speed sensor;

[0070] Acquiring a first pressure value of the driving pressure detected by the driving pressure sensor;

[0071] obtaining a second pressure value of the pressure in the suspension cylinder detected by the suspension pressure sensor;

[0072] Obtain the elongation of the piston rod of the suspension cylinder detected by the suspension stroke encoder;

[0073] According to the rotational speed value, the first pressure value, the second pressure value and the elongation, it is judged whether the driving wheel is on a potholed road; when it is judged that the driving wheel is on a potholed road, a Turn off the control signal.

[0074] In the above process, the basis for judging whe...

Embodiment 3

[0079] The present invention also provides a control method of the differential speed control system of the molten iron car, the control method comprising:

[0080] Obtain the rotational speed value of the rotational speed of the current drive motor detected by the motor rotational speed sensor;

[0081] Acquiring a first pressure value of the driving pressure detected by the driving pressure sensor;

[0082] obtaining a second pressure value of the pressure in the suspension cylinder detected by the suspension pressure sensor;

[0083] Obtain the elongation of the piston rod of the suspension cylinder detected by the suspension stroke encoder;

[0084] According to the rotational speed value, the first pressure value, the second pressure value and the amount of elongation, it is judged whether the driving wheel is in the state of low tire adhesion; The solenoid valve sends a closing control signal.

[0085] In this embodiment, the basis for judging that the driving wheel t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com