Reciprocating supercharger capable of stably reversing

A reciprocating, supercharger technology, applied in the direction of fluid pressure converters, mechanical equipment, etc., can solve the problems of affecting the reversing speed, poor output pressure stability, small flow rate of the electromagnetic reversing valve, etc., to reduce manufacturing costs and failures speed, reducing shock, increasing stability and speed of commutation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

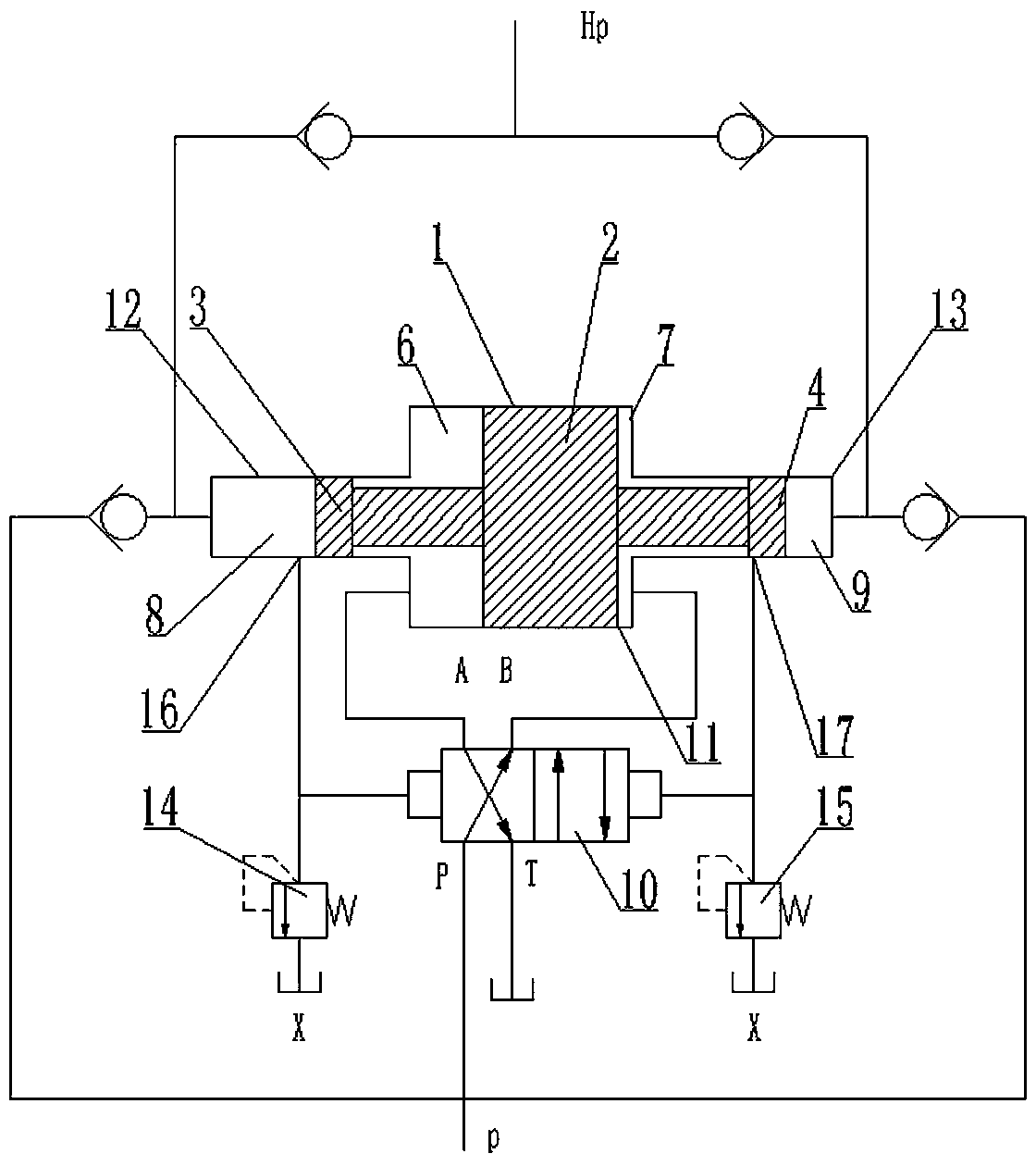

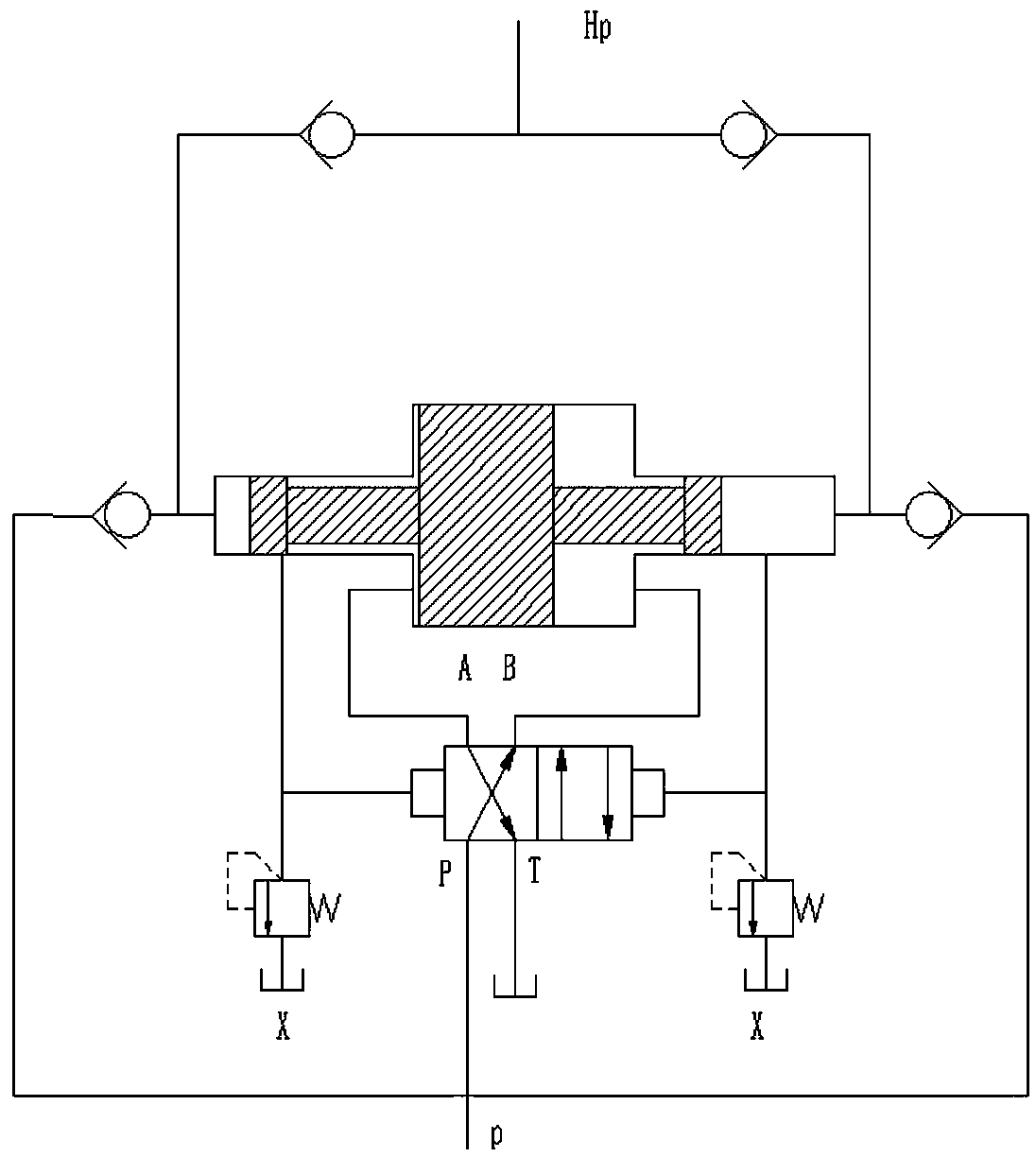

[0012] Such as figure 1 As shown, a hydraulically controlled reciprocating booster includes a reciprocating booster cylinder, an electromagnetic reversing valve 10, a left overflow valve 14, and a right overflow valve 15. The reciprocating booster cylinder includes a cylinder body 1, which is composed of a piston cylinder 11 in the middle and a left booster cylinder 12 and a right booster cylinder 13 at both ends. The piston 2 is arranged in the piston cylinder 11, and the left piston rod 3 is arranged in the left In the boost chamber, the right piston rod 4 is arranged in the right boost cylinder 13, the outer diameters of the left and right piston rod ends match the inner diameters of the left and right boost cylinders, and the outer diameter from the end to the piston is smaller than the outer diameter of the ends. The left piston cavity 6 is formed between the piston 2, the piston cylinder 11, the left booster cylinder 12, and the ends of the left piston rod 3, and the rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com