Reinforced grouting seal ring structure for offshore wind power pile foundation by first piling method

A technology for offshore wind power and sealing rings, which is applied in infrastructure engineering, construction, etc., can solve the problems of waste of grouting materials, easy failure, damage and tearing of grouting sealing rings, and achieve the goal of reducing the loss of grouting materials, convenient implementation and easy realization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

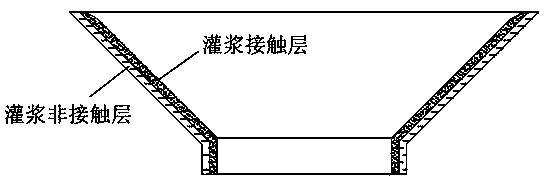

[0026] Figure 4 and Figure 5 The first reinforcement method is shown. The hierarchical structure of the sealing ring structure 8 includes a grouting contact layer and a grouting non-contact layer. The grouting contact layer adopts the upper rubber layer 13, and the grouting non-contact layer adopts the middle reinforcing fiber layer 14 and the bottom rubber layer 16. structure. During the manufacturing process of the sealing ring, one or more layers of mesh or strip tough fiber material are implanted inside the sealing section. The number of implanted layers of the material can be set according to the grouting pressure and the thickness of the steel pipe.

Embodiment 2

[0028] Image 6 and Figure 7 The second reinforcement method is shown. The hierarchical structure of the sealing ring structure 8 includes a grouting contact layer and a grouting non-contact layer. The grouting contact layer adopts the upper rubber layer 13, and the grouting non-contact layer adopts the bottom hard reinforcing mesh layer 15 structure. At the bottom of the sealing ring, that is, on the non-contact side of the sealing ring and the grouting material, a dense hard reinforcing mesh layer is set. The material has a certain strength, hardness and wear resistance. The material can be provided with one or more layers according to needs. ;During the installation process, even if the sealing ring and pile head burrs, sharp corners, and protrusions produce interference friction, but the bottom of the sealing ring is in contact with the reinforcing mesh layer, which will protect the sealing ring from being torn and worn. Protect it from damage.

Embodiment 3

[0030] Figure 8 The third reinforcement method is shown. The hierarchical structure of the sealing ring structure 8 includes a grouting contact layer and a grouting non-contact layer. The grouting contact layer adopts the upper rubber layer 13, and the grouting non-contact layer adopts the middle reinforcing fiber layer 14 and the bottom hard reinforcement Net layer 15 structure. During the manufacturing process of the sealing ring, one or more layers of mesh or strip tough fiber material are implanted inside the sealing section. The number of implanted layers of the material can be set according to the grouting pressure and the thickness of the steel pipe. On the non-contact side of the sealing ring and the grouting material, a dense hard reinforcing mesh layer is set. The material has certain strength, hardness and wear resistance. The material can be set in one or more layers according to needs; during the installation process, Even if the sealing ring and pile head burrs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com