Multifunctional spray fun for mechanical arm

A multi-functional, spraying gun technology, applied in the field of spraying guns, can solve the problems of high labor intensity, low labor efficiency, poor workpiece quality, etc., and achieve the effect of preventing the spray head from hitting the sprayed parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

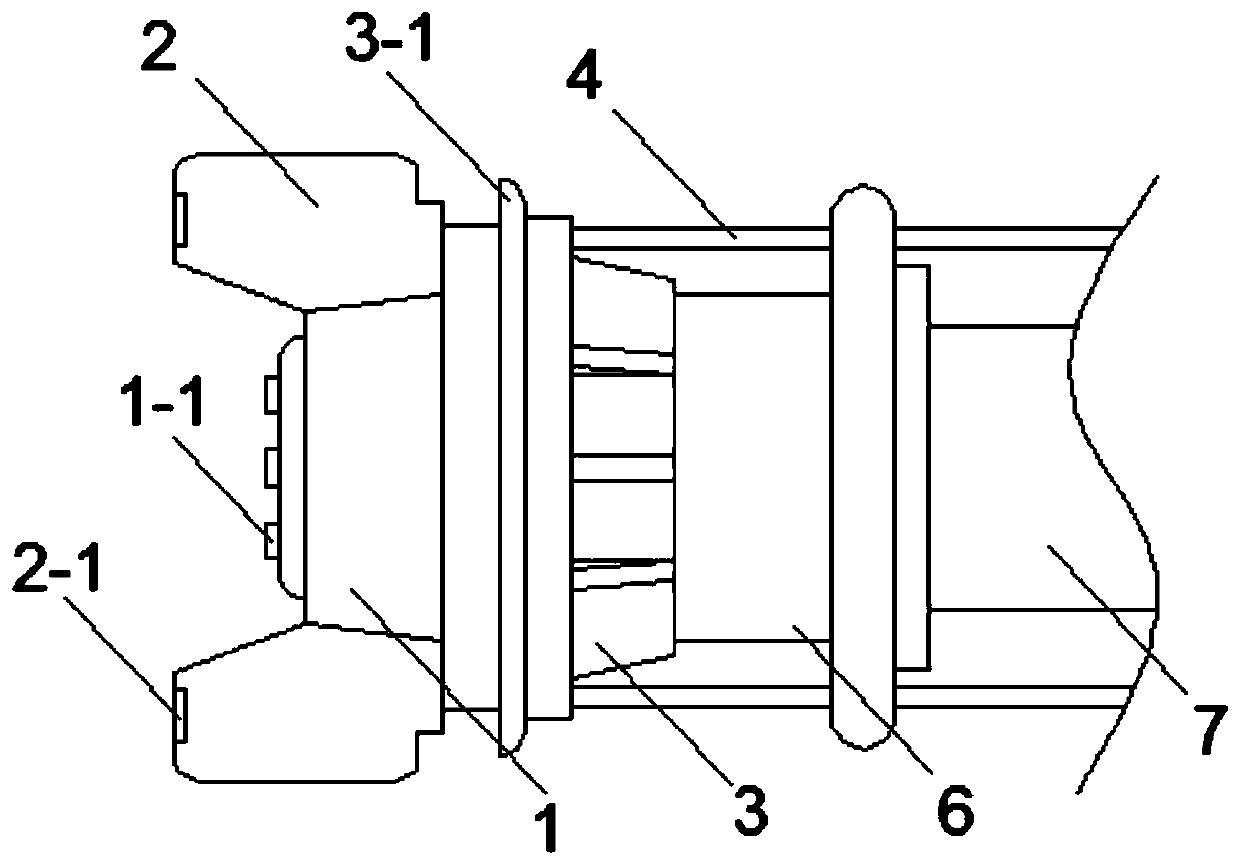

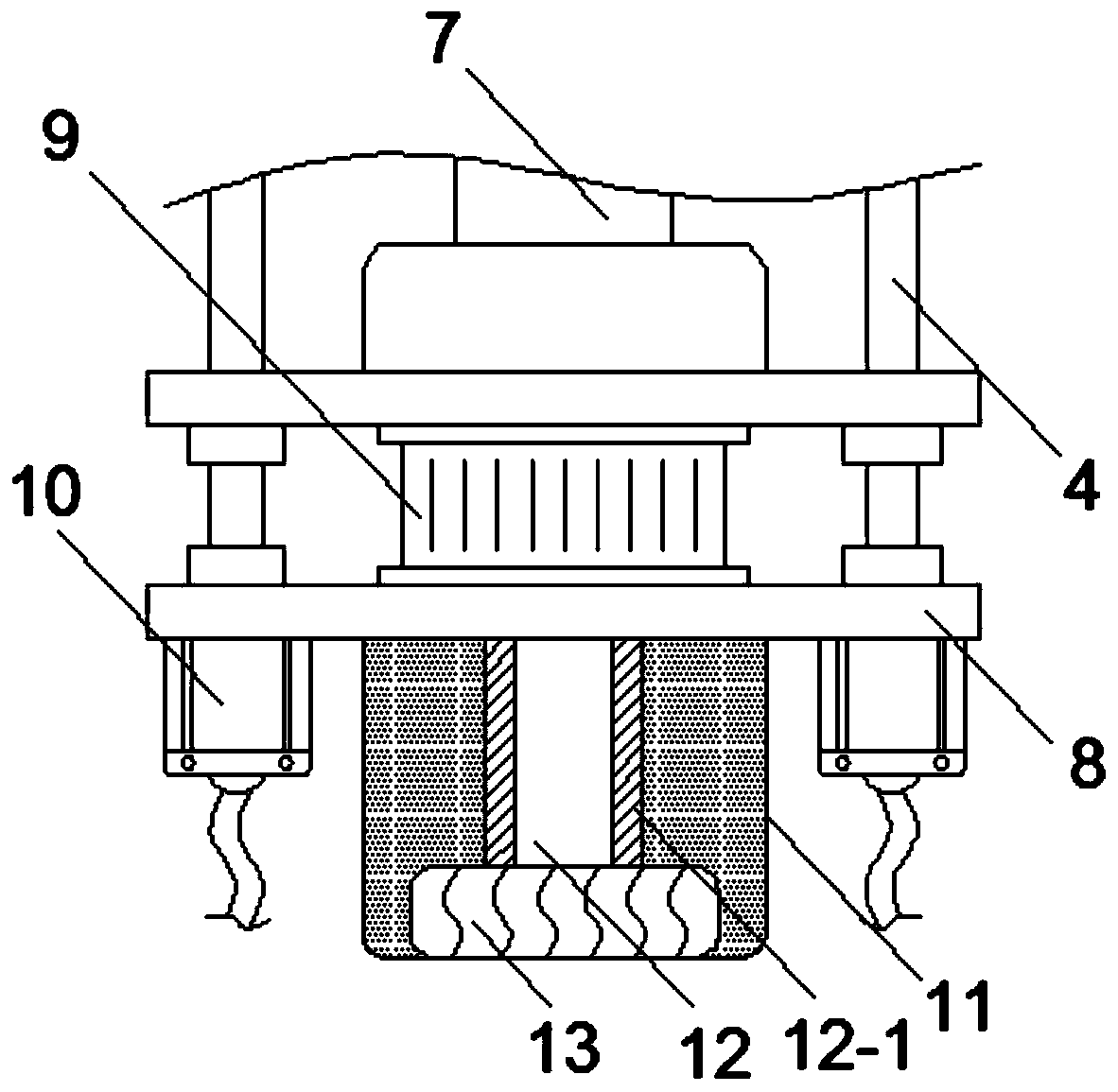

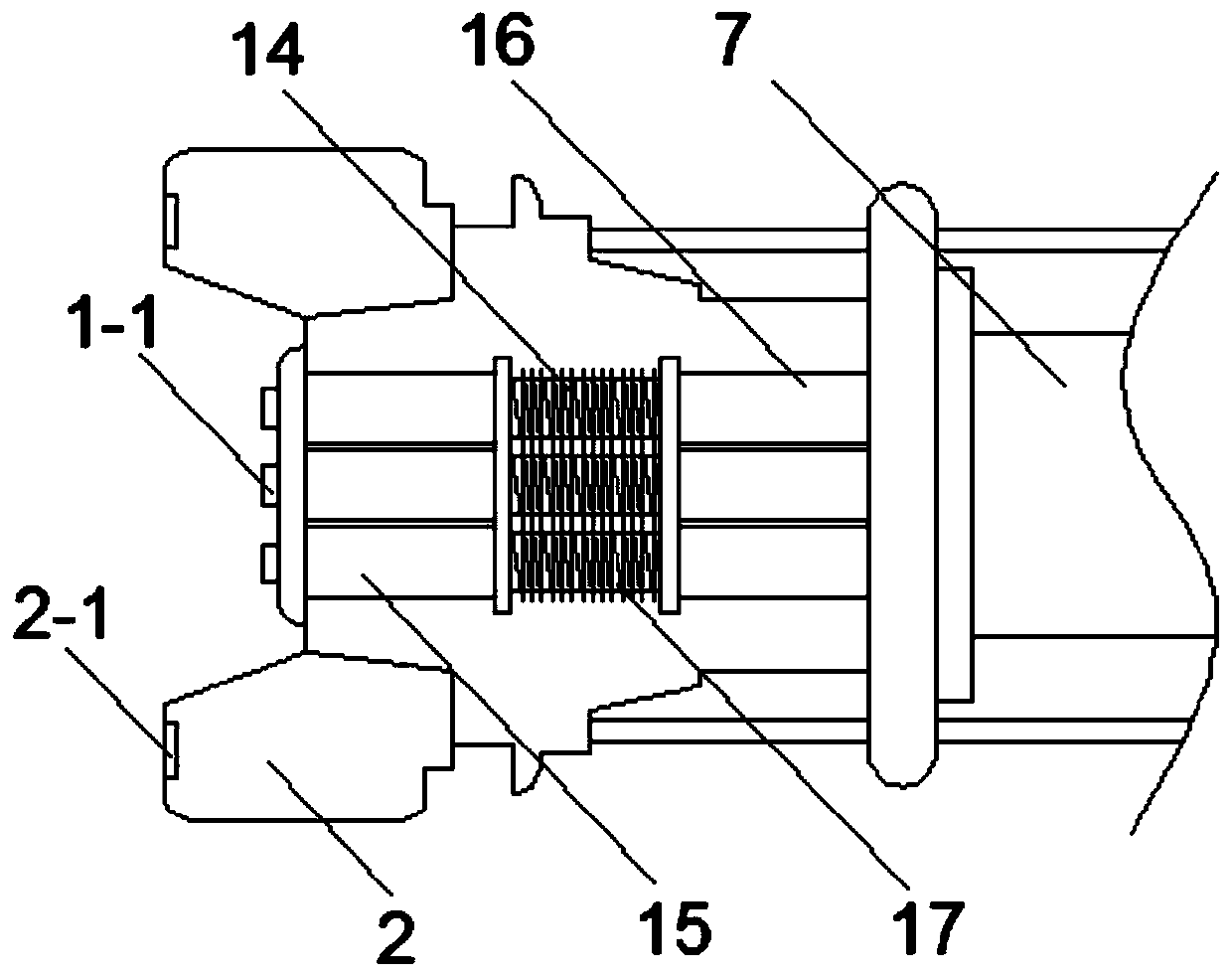

[0015] Such as figure 1 , figure 2 and image 3 Shown, a kind of multi-functional spray gun for manipulator, comprises spray gun head and paint tank; Described spray gun head 1 top is embedded with several groups of nozzles 1-1, and described nozzle 1-1 is communicated with paint tank 11 through feeding pipe 14 , the bottom of the paint tank 11 is equipped with a turbine 13, the top interface of the turbine 13 is connected to the output port of the motor 9 through the hollow shaft 12, and the bottom input port of the delivery chamber 12-1 built in the hollow shaft 12 is connected to the turbine 13 The output port is connected, and the delivery chamber 12-1 communicates with the delivery tube 14. Wherein, the turbine 13 draws the paint inside the paint tank 11 to the nozzle 1-1 for spraying in the form of negative pressure. During the spraying process, the output port of the motor 9 is equipped with a hollow shaft 12, and the delivery chamber 12-1 built in the hollow shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com