A kind of preparation method of polymer solution containing quaternary ammonium salt, tertiary ammonium salt and tertiary amine on the main chain

A quaternary ammonium salt and polymer technology, applied in the field of polymer solution preparation, can solve problems such as synthesis process route, preparation method and research on antistatic properties that have not yet been reported in literature, and achieves omitting separation and purification steps, reducing orderly Sex and symmetry, the effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

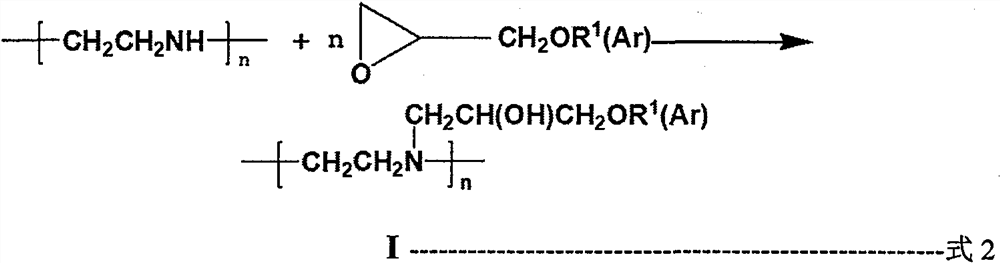

Method used

Image

Examples

Embodiment 1

[0056] First, under the protection of nitrogen, 28.00 grams of diethylene glycol methyl ethyl ether, 32.00 grams of diethylene glycol dipropionate, 33.00 grams of diethylene glycol ethyl ether acetate and 41.00 grams of propylene carbonate, 4.30 grams of PEI30000, 1.86 grams of n- Octyl glycidyl ether, 2.96 grams of glycidol and 5.10 grams of ethyl glycidyl ether are mixed, and the tertiary amination reaction is carried out while stirring. The reaction temperature is 30°C, and the reaction time is 20h. After the reaction, a solution of tertiary amine polymer I is obtained. Secondly, under the protection of nitrogen, the solution of the obtained tertiary amine polymer I was mixed with 1.11 grams of 3-chloroglycerin and 1.51 grams of n-pentane bromide and stirred for quaternization reaction, the reaction temperature was 90 ° C, and the reaction time was 6h , react to obtain a solution of polymer II containing both quaternary ammonium salts and tertiary amines on the main chain; t...

Embodiment 2

[0058]First, under the protection of nitrogen, 38.00 grams of triethylene glycol diacetate, 45.00 grams of ethylene glycol dibutyl ether, 25.00 grams of ethylene carbonate, 1.20 grams of PEI3000, 1.20 grams of PEI60000, 1.47 grams of PEI10000, 6.50 grams of n-butyl Base glycidyl ether and 4.08 grams of ethyl glycidyl ether are mixed and stirred to carry out tertiary amination reaction, the reaction temperature is 40 ℃, and the reaction time is 18h, and the solution of tertiary amine polymer I is obtained after the reaction; secondly, under nitrogen protection, Mix and stir the solution of the obtained tertiary amine polymer I with 2.78 grams of 3-bromo-1-propanol and 1.65 grams of n-hexane bromide for quaternization reaction. The reaction temperature is 85° C., and the reaction time is 8 hours. The solution of polymer II containing quaternary ammonium salt and tertiary amine at the same time; thirdly, the solution of obtained polymer II is treated with strong basic anion exchan...

Embodiment 3

[0060] First, under nitrogen protection, 49.00 grams of diethylene glycol methyl ether acetate, 15.00 grams of N, N-dimethylformamide, 17.00 grams of ethylene carbonate, 19.00 grams of N, N-dimethylformamide, 5.16 gram of PEI35000, 9.00 gram of phenyl glycidyl ether and 4.44 gram of glycidol were mixed and stirred for tertiary amination reaction, the reaction temperature was 50°C, and the reaction time was 15h. After the reaction, the solution of tertiary amine polymer I was obtained; Under protection, mix and stir the obtained tertiary amine polymer I solution with 4.75 g of 3-chloro-1-propanol for quaternization reaction, the reaction temperature is 80°C, and the reaction time is 10 hours. The solution of the polymer II of the ammonium salt and the tertiary amine; thirdly, the solution of the obtained polymer II is treated with a strong basic anion exchange resin until no halogen ion is detected, and the main chain contains a quaternary ammonium base and a tertiary amine at t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal stability | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com