A rubber shock absorber for trains with reduced rubber deformation

A technology of rubber shock absorbers and trains, applied in the direction of spring/shock absorber, vibration suppression adjustment, non-rotational vibration suppression, etc., can solve the problems of weak bearing capacity, inconsistent shock absorption effect of rubber shock absorbers, low hardness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

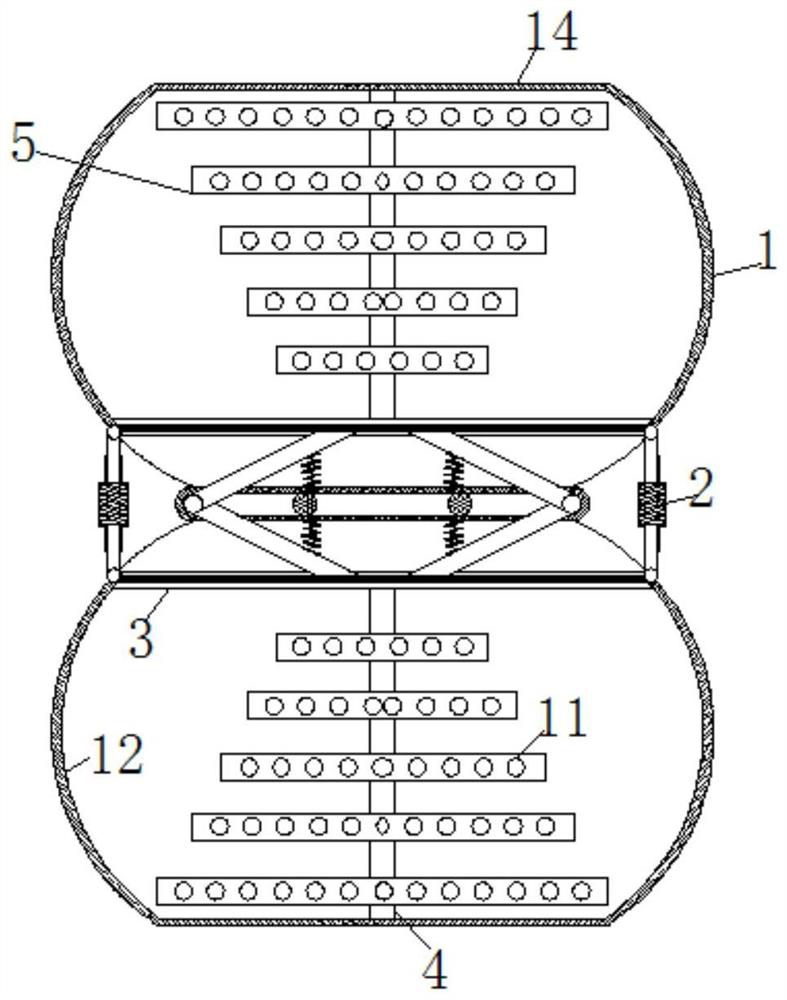

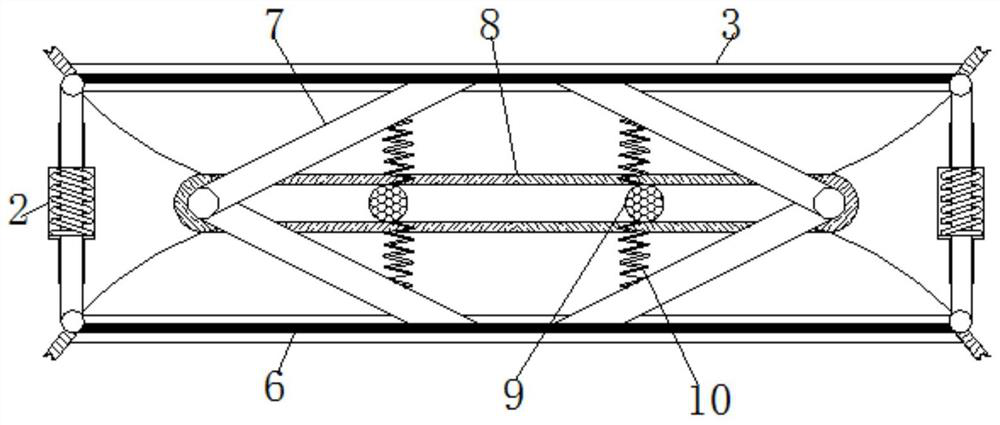

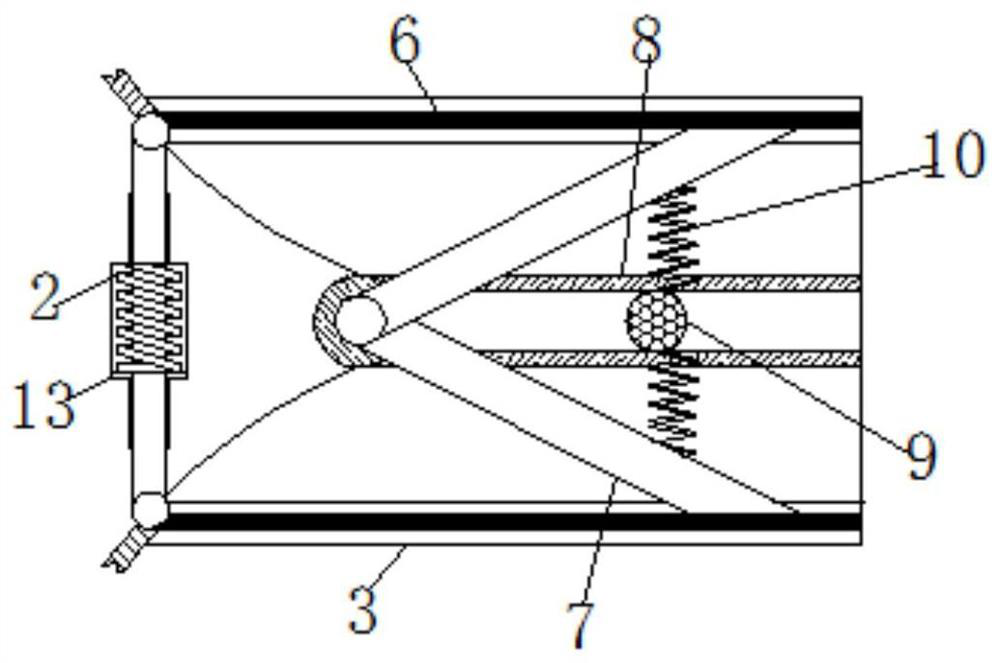

[0023] see Figure 1-5 , a rubber shock absorber for trains that reduces rubber deformation, including a colloid 1, the colloid 1 is oval, which is convenient for deformation and suction of gas, and both ends of the colloid 1 are fixedly connected with load-bearing plates 14, which play a role in connecting with a certain part of the train. The inner side wall of colloid 1 is provided with chute 12, which acts as a guide. The surface of colloid 1 is movably co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com