Liftable small-sized process control experiment teaching device

A process control and teaching device technology, applied to teaching models, educational tools, instruments, etc., can solve problems such as unintuitive simulation of height drops, failure to meet the requirements of experiments, and failure to meet teaching tests, etc., to facilitate later maintenance, The device is stable and reliable, and the effect of ensuring sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

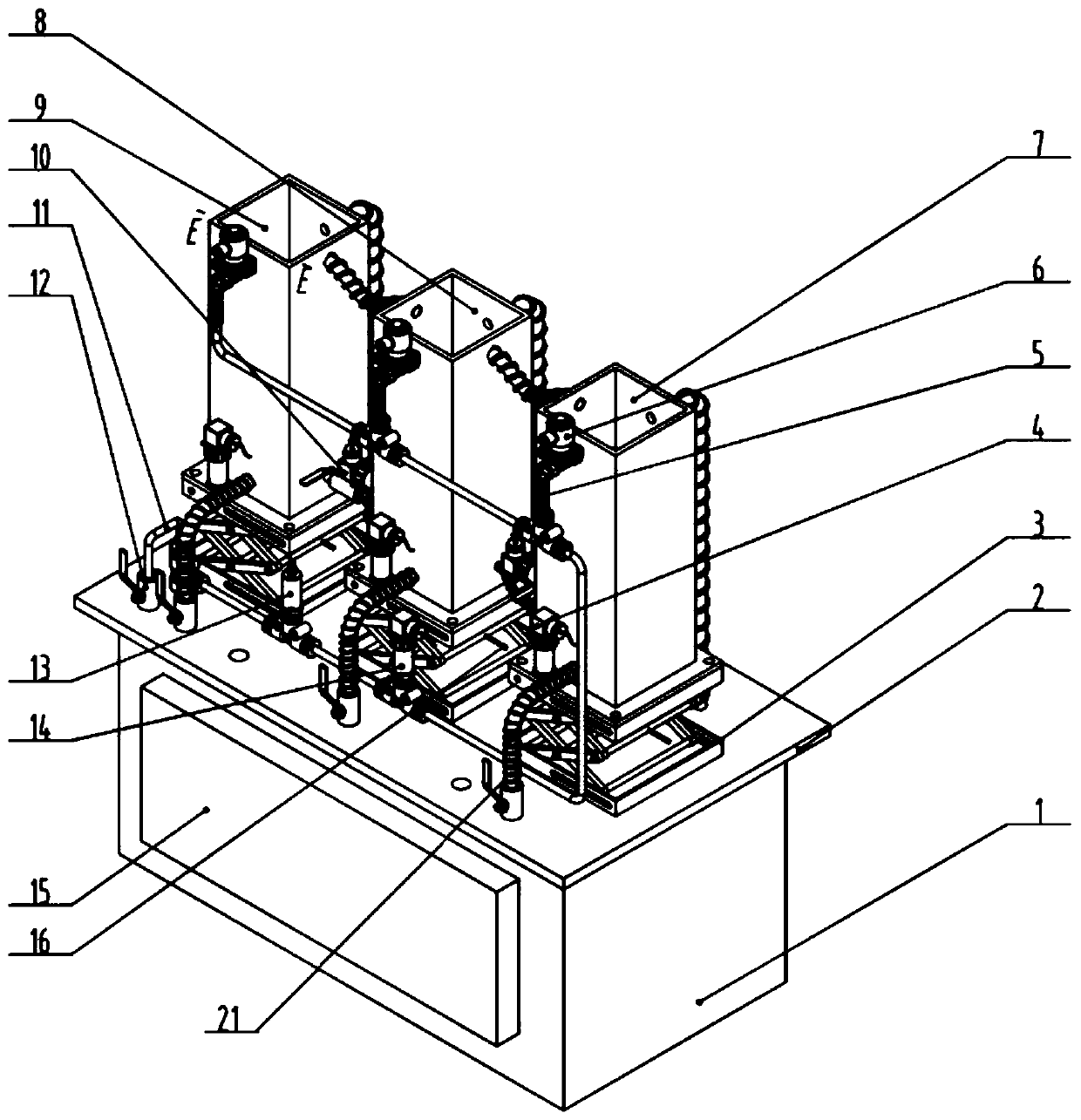

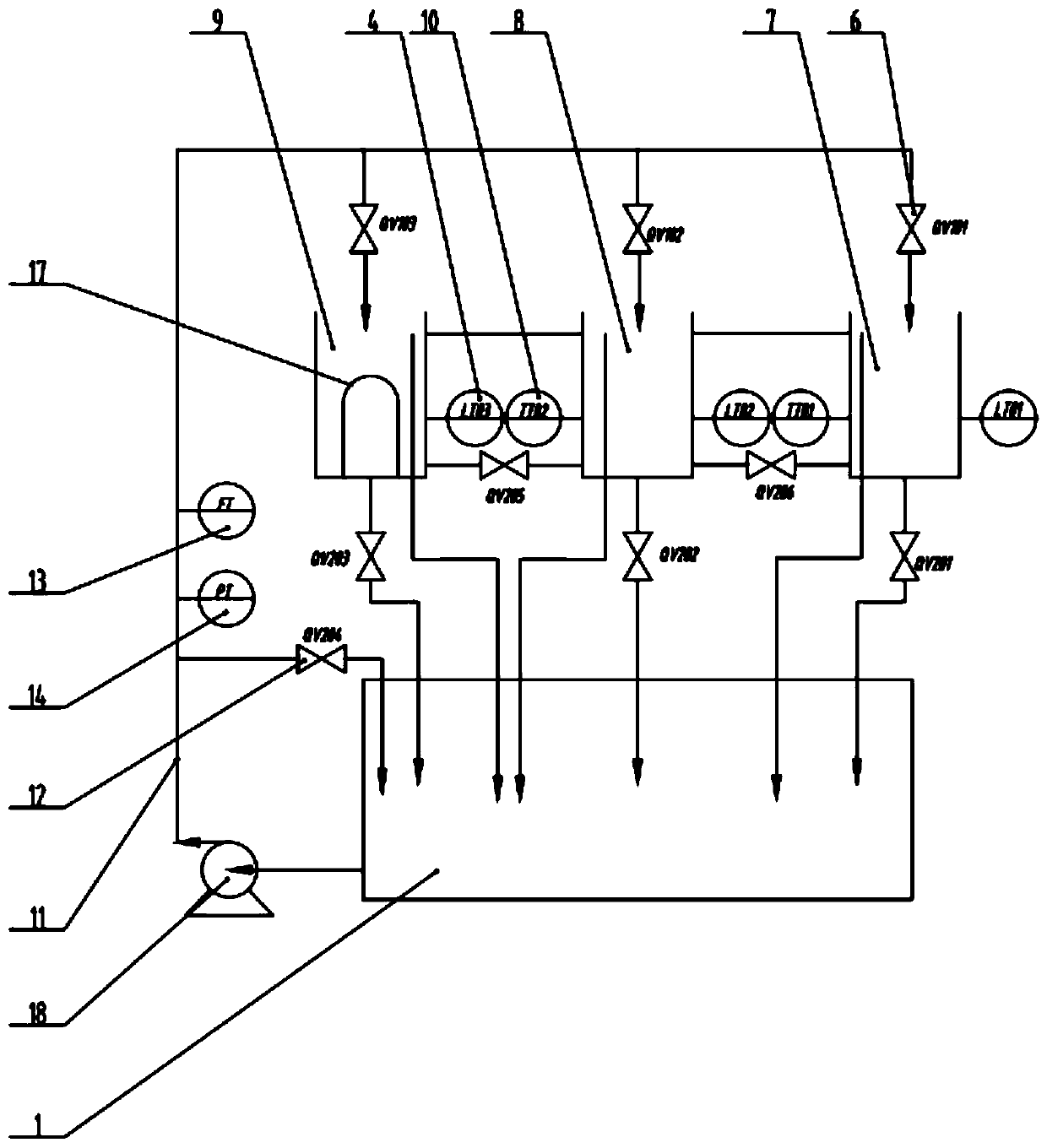

[0045] see Figure 1~3, in the example of the present invention, a small-scale process control experimental teaching device that can be lifted includes a water tank 1, a water tank cover plate 2, a lifting device 3, a liquid level gauge 4, a metal hose 5, a branch valve 6, a No. 1 container 7, No. 2 container 8, No. 3 container 9, temperature sensor 10, inlet pipeline main section 11, inlet valve 12, flow meter 13, pressure sensor 14, controller connecting plate 15, threaded rod 16, heating device, PWM submersible pump 18, The water tank cover plate 2 is fixed on the water tank 1, and there are three containers in total: the No. 1 container 7, the No. 2 container 8, and the No. 3 container 9. The tops of the three containers are connected through connecting pipes, and the connecting pipes are metal hoses. And the three containers are equipped with overflow pipelines, the overflow pipelines are metal hoses, the setting of the three overflow pipelines realizes the overflow prote...

Embodiment 2

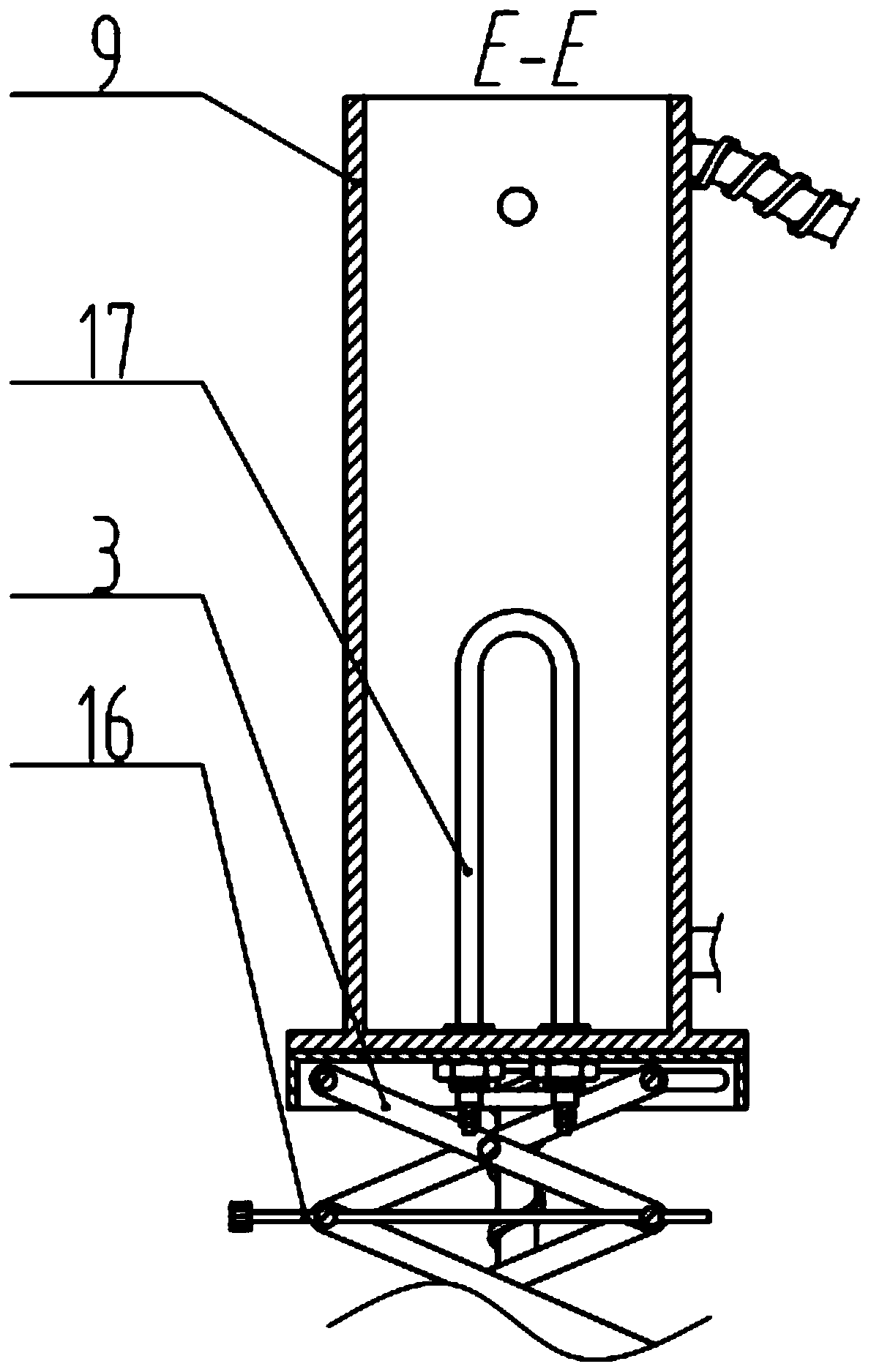

[0047] Such as figure 1 , 3 , 4, 5, 6, and 7, the three lifting devices 3 are specifically small-scale mechanical shear lifts, which are respectively located at the bottom of No. 1 container 7, No. 2 container 8, and No. 3 container 9, and are connected to the water tank cover 2; the three lifting devices 3 are independent of each other. When the limit position is not reached, the three lifting devices will not interfere with each other. The mutual independence of the lifting devices 3 makes the first container 7, the second container 8 and the third container No. 9 containers are independent of each other, so that the relative vertical displacement between the three containers can be changed. The change of the relative vertical displacement between the three containers has very important applications in real scenes. If you want to implement water supply to different floors of an apartment, you can first conduct simulation analysis through this experimental device, and first ...

Embodiment 3

[0052] The U-shaped heating tube 17 is located inside the No. 3 container 9, and the number is one. The temperature sensor 10 is located in the No. 1 container 7, the No. 2 container 8, and the No. 3 container 9, and the number is three. Start the PWM submersible pump 18 to keep the inlet Valve 12, outlet valve 21 opening degrees are constant, set the target temperature in the No. 3 container 9, open the U-shaped heating tube 17 in the No. 3 container 9 to start heating, and the temperature sensor 10 measures the real-time temperature in the container, which can be used to The pure hysteresis experiment under simulated temperature control (the time required from setting the set temperature to detecting that the temperature reaches the set value is the lag time), and the application in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com