Sales-dominated factory information management system

An information management system and factory technology, applied in the direction of data processing applications, instruments, resources, etc., can solve the problems of little involvement in the production process, no clear plan for sales, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

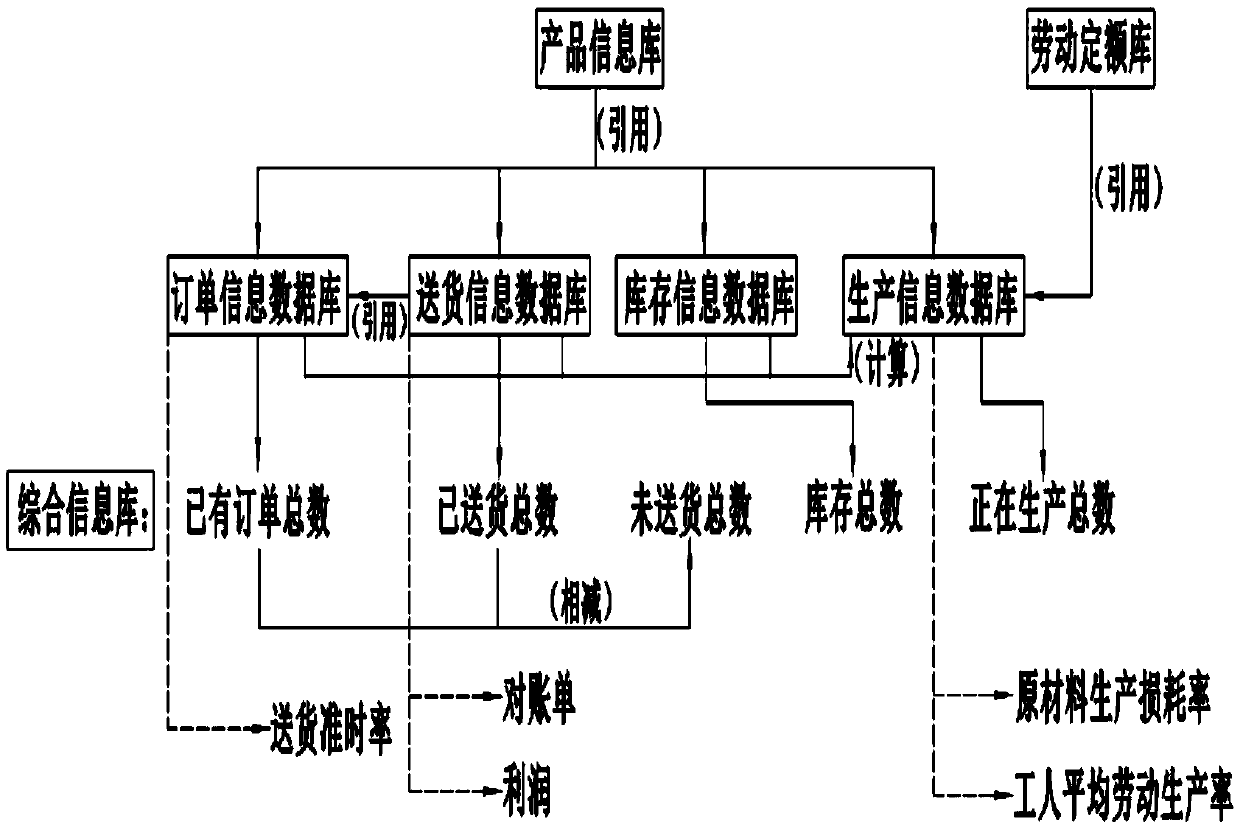

[0038] A sales-oriented factory information management system of the present invention, such as figure 1 As shown, including product information database, order information database, delivery information database, inventory information database, production information database, order information database, delivery information database, inventory information database, production information database refer to the corresponding information from the product information database respectively, Get the total number of existing orders from the order information database, get the total number of delivered goods from the delivery information database, and then get the total number of undelivered goods; get the total number of stocks from the inventory information database, according to the order information database, delivery information database, inventory The information database obtains the production information through calculation, and obtains the total number of products being prod...

specific Embodiment approach 2

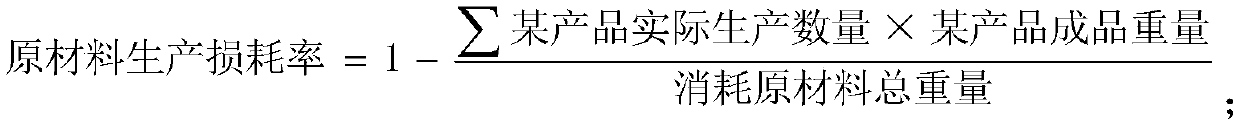

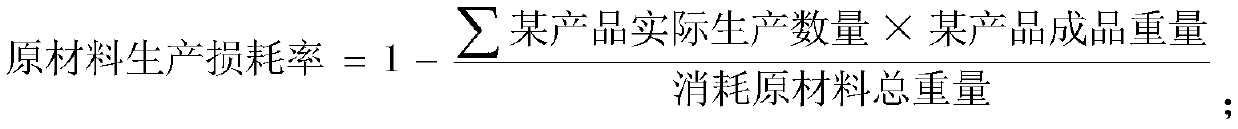

[0053] In the sales-oriented factory information management system of the present invention, the on-time rate of delivery, the loss rate of raw material production, the average labor productivity of workers, and the factory profit are calculated by the following formulas respectively:

[0054] On-time delivery rate = output value of products delivered on time during the calculation period / output value of products to be delivered during the calculation period;

[0055]

[0056] Average labor productivity of workers = calculation period output value / number of workers;

[0057] Factory profit = output value in the calculation period - cost in the calculation period.

specific Embodiment approach 3

[0059] According to the sales-oriented factory information management system of the present invention, according to the order quantity in the order information database and the delivered quantity in the delivery information database, an order list of all orders of a certain product arranged according to the delivery date is obtained, according to The delivery note is based on the delivery list of the delivery date, so as to obtain the corresponding relationship between the order quantity and the delivery note, and determine the order status. Specifically, the actual delivery date is obtained by comparing the existing order quantity of a certain product with the delivered quantity:

[0060] A. First, line up all orders for a certain product according to the planned delivery date;

[0061] B. Then line up the delivery order according to the delivery date;

[0062] C. Then the order quantity increases sequentially from front to back, and is compared with the sequential increase ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com