Adhesion treatment process of semisteel molten iron tank in converter smelting

A processing technology, converter smelting technology, applied in the direction of manufacturing converters, etc., can solve the problems of reducing the life of molten iron tanks, affecting the turnover of molten iron, reducing production efficiency, etc., to solve the turnover problem, improve service life and production efficiency, and improve production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

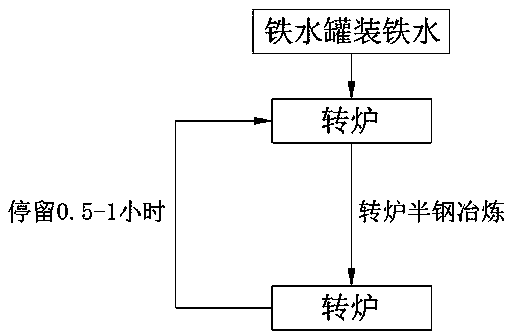

[0010] refer to figure 1 , a converter smelting semi-steel ladle tank sticking treatment process, said treatment process is: the converter is filled with molten iron according to the remaining tank capacity of the molten iron tank, blowing for 3-5 minutes, adding magnesium balls and lime during blowing, Among them, the amount of magnesium balls added is 8kg / t iron, the amount of lime added is 30kg / t iron, the tapping temperature is controlled at 1550-1600°C, and the semi-steel is discharged into the molten iron tank, and the semi-steel is stopped in the molten iron tank for 0.5 - Add iron to the converter after 1 hour, and each time half steel can boil about 10 tons of molten iron; the more optimal blowing time is 4 minutes, and the tapping temperature is 1575°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com