A rapid processing milling machine based on wood mortise and tenon joint

A tenon joint and keyway technology, applied in the field of milling machines, can solve the problems of intermittent sluggish wood processing, vibrating tool rest, labor-intensive and other problems, and achieve the effect of seamless splicing, high efficiency and continuity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

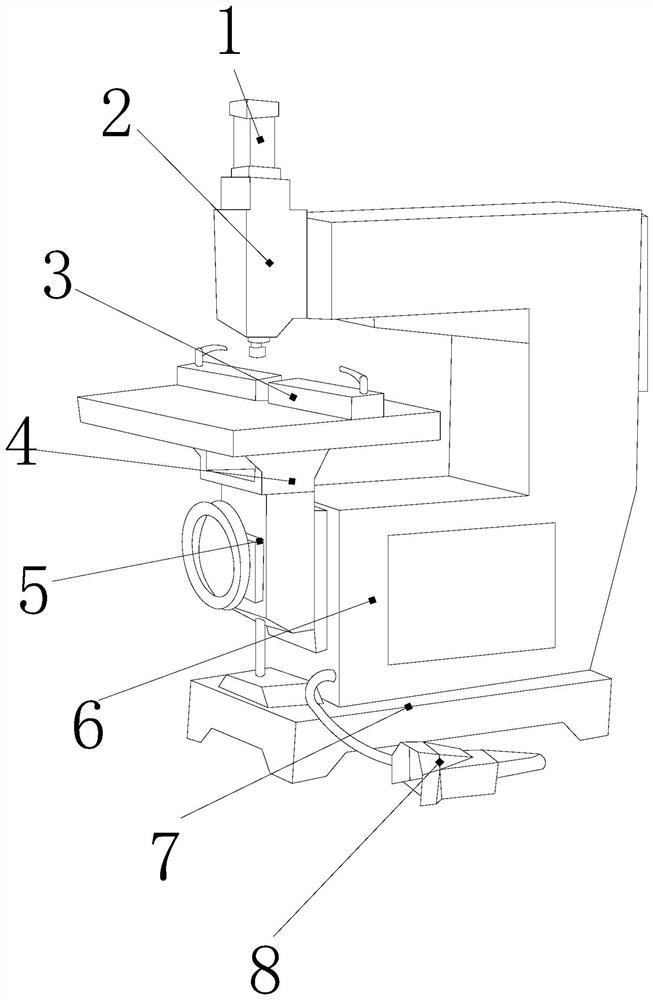

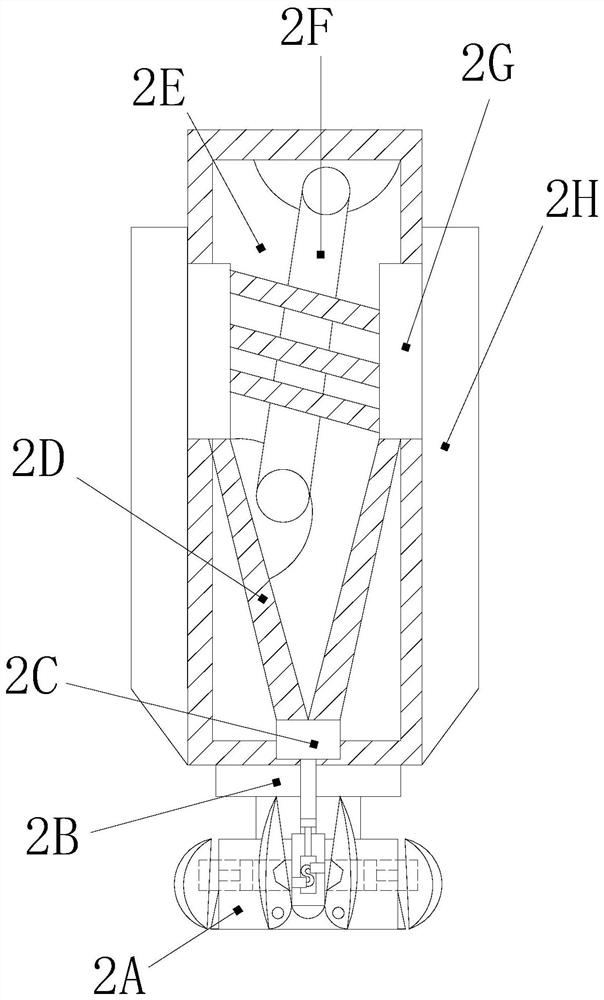

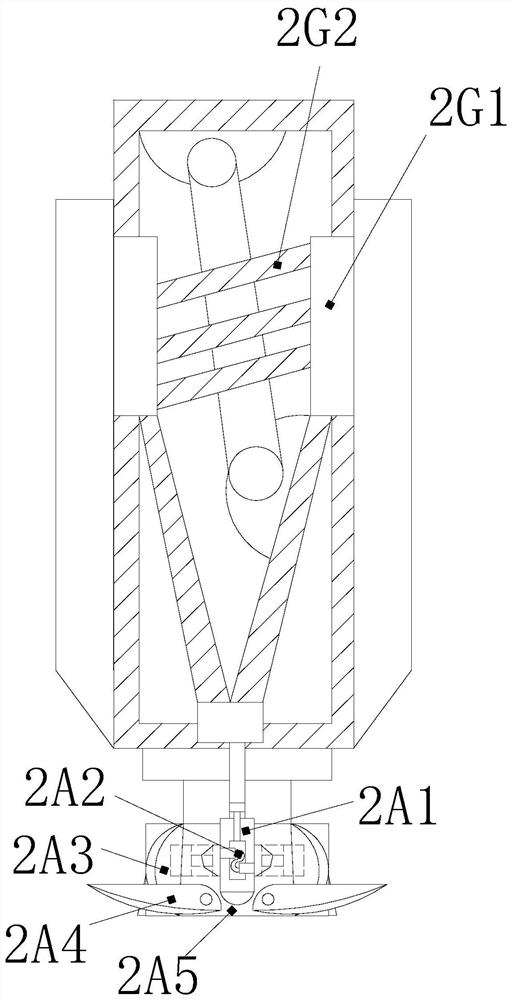

[0031] see Figure 1-Figure 7 , the present invention provides a fast processing milling machine based on wood mortise and tenon joint keyway expansion and knife punching. , roulette lifting column 5, arm grip bracket block 6, base plate 7, power distribution plug 8, the milling cutter shear frame 2 is nested under the bottom of the shaft motor 1, and the milling cutter shear machine The frame 2 is closely attached to the upper left corner of the arm support block 6, the arm support block 6 is welded on the top surface of the base plate 7, and the power distribution plug 8 is electrically connected to the electric board inside the arm support block 6 , the concave bracket seat 4 is welded on the top of the roulette lifting column 5, the roulette ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com