Internal resistance test system and method of fuel cell stack

A fuel cell stack and internal resistance test technology, applied in the direction of fuel cells, circuits, electrical components, etc., can solve the problems of long test time, high difficulty, danger of instantaneous current cut off, etc., to achieve the required time period for the test, easy to operate , easy to implement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

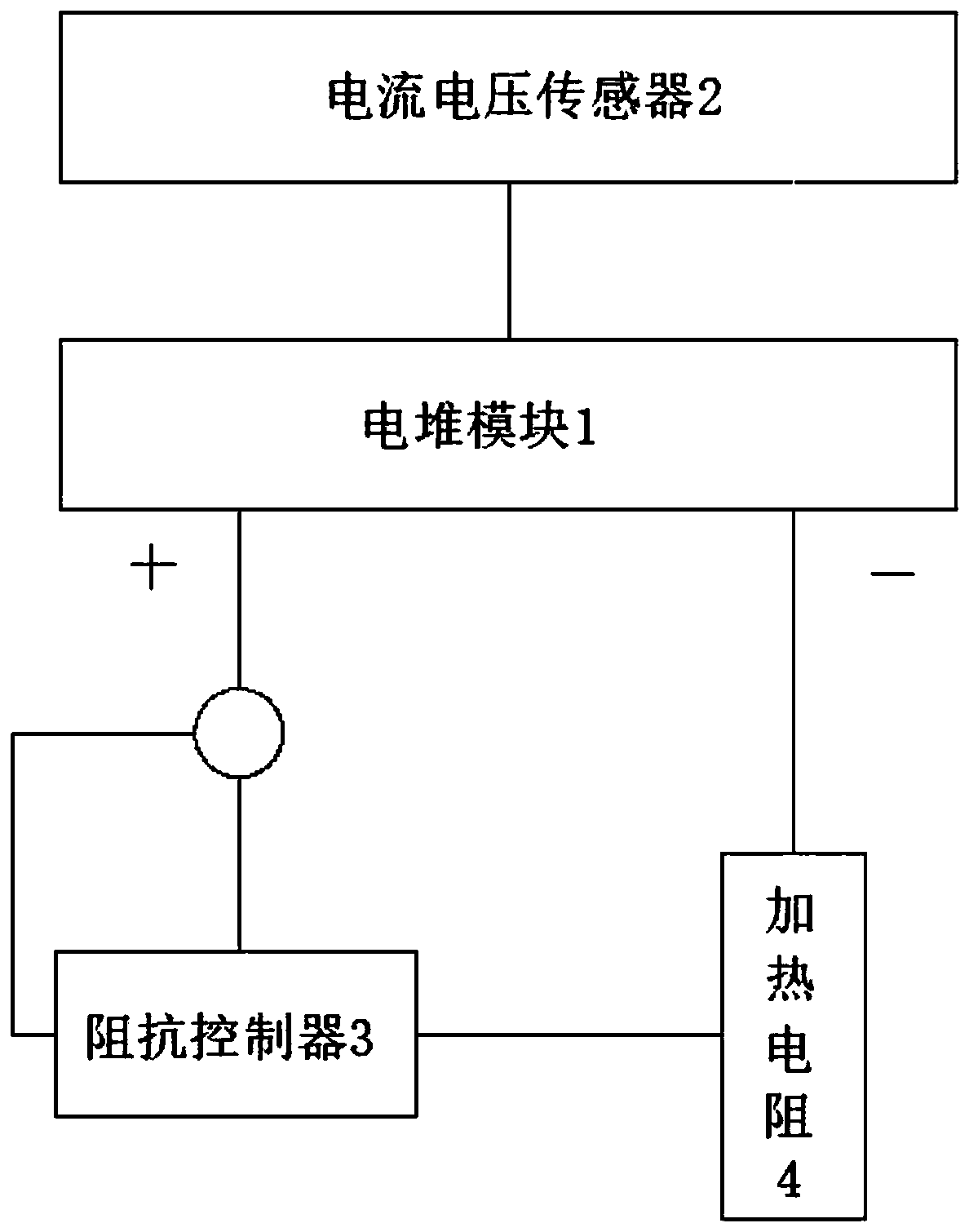

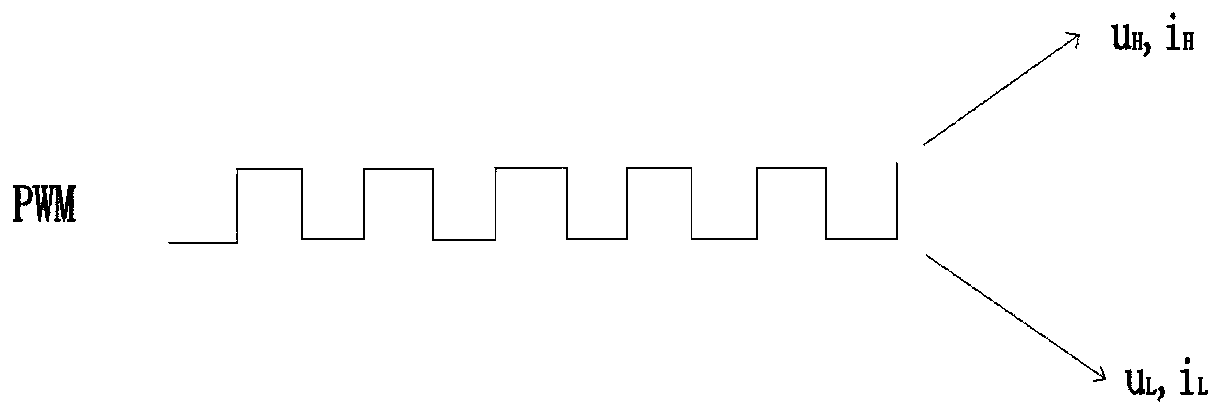

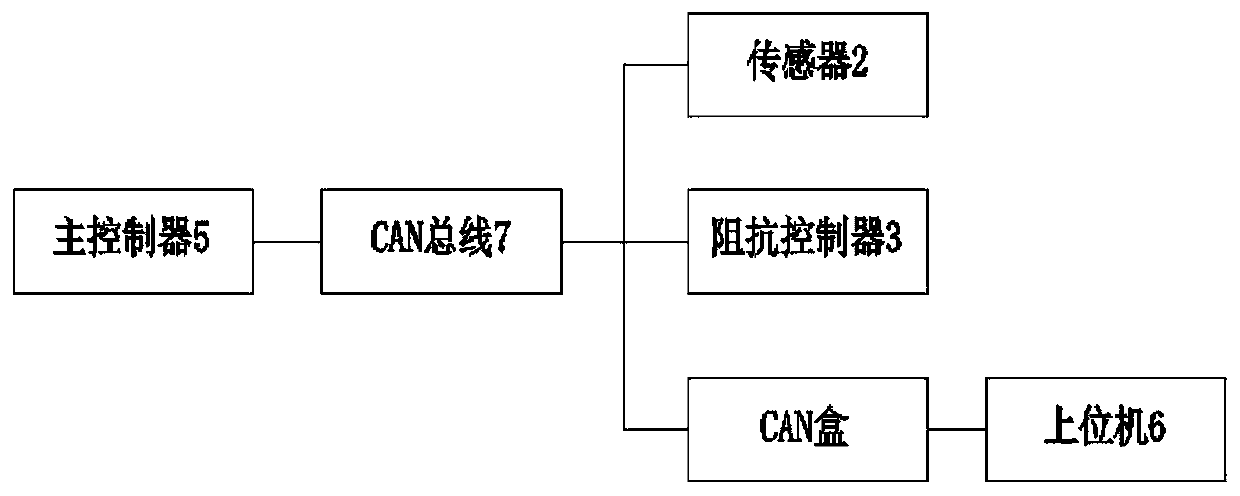

[0029] Such as Figure 1 to Figure 4 As shown, this embodiment provides a fuel cell stack internal resistance testing system, including a stack module 1, a sensor 2, an impedance controller 3, a heating resistor 4, a main controller 5, and a host computer 6. The heating resistor 4 , the impedance controller 3 is connected in series with the electric stack module 1, the heating resistor 4 is used to provide a heat radiation source for the electric stack module 1, and the impedance controller 3 continuously sends a PWM square wave signal to the electric stack module 1 for providing the electric stack mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com