Composite driving hoisting device

A hoisting device and composite technology, applied in cranes and other directions, can solve the problems of large structural size and high environmental adaptability, and achieve the effects of easy disassembly, simple structure, and extended working life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

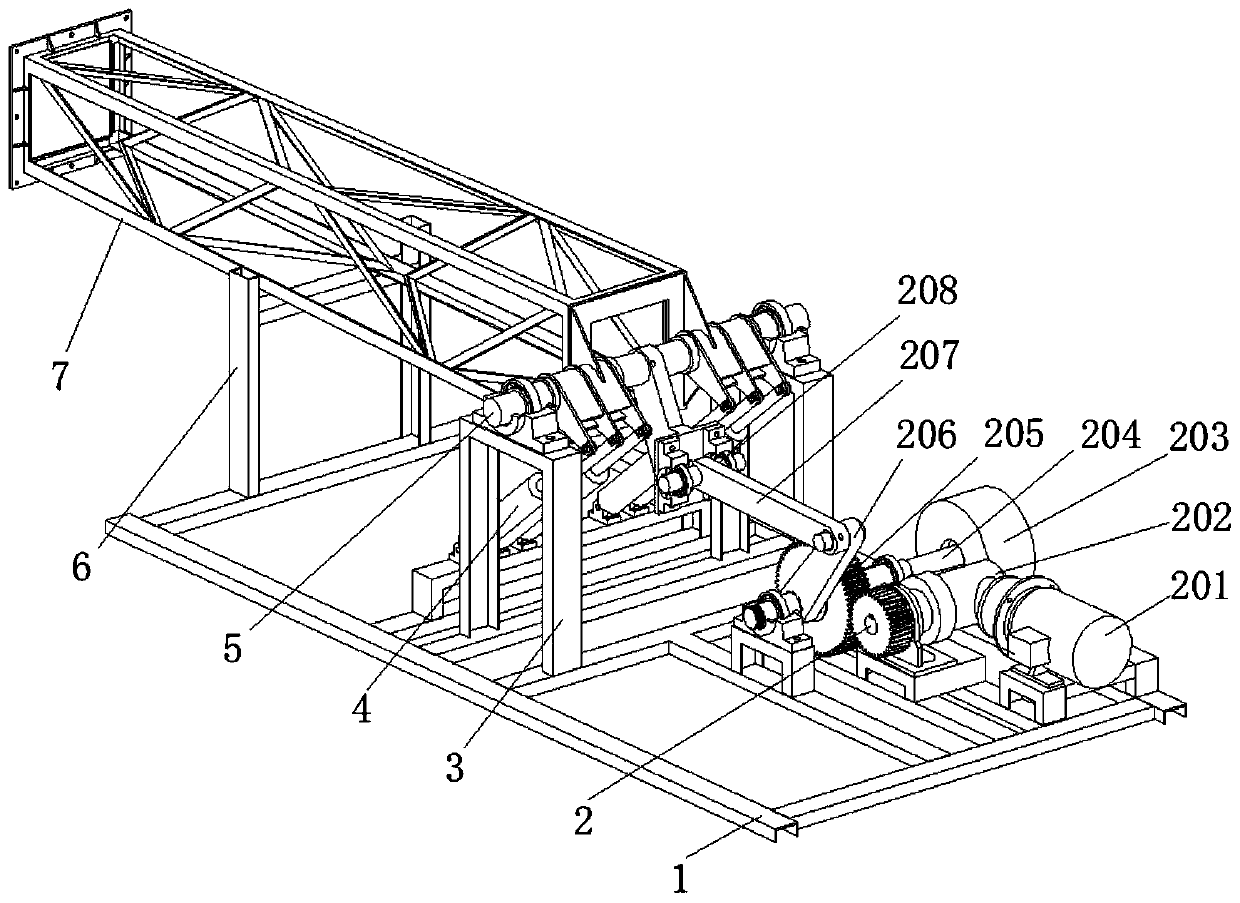

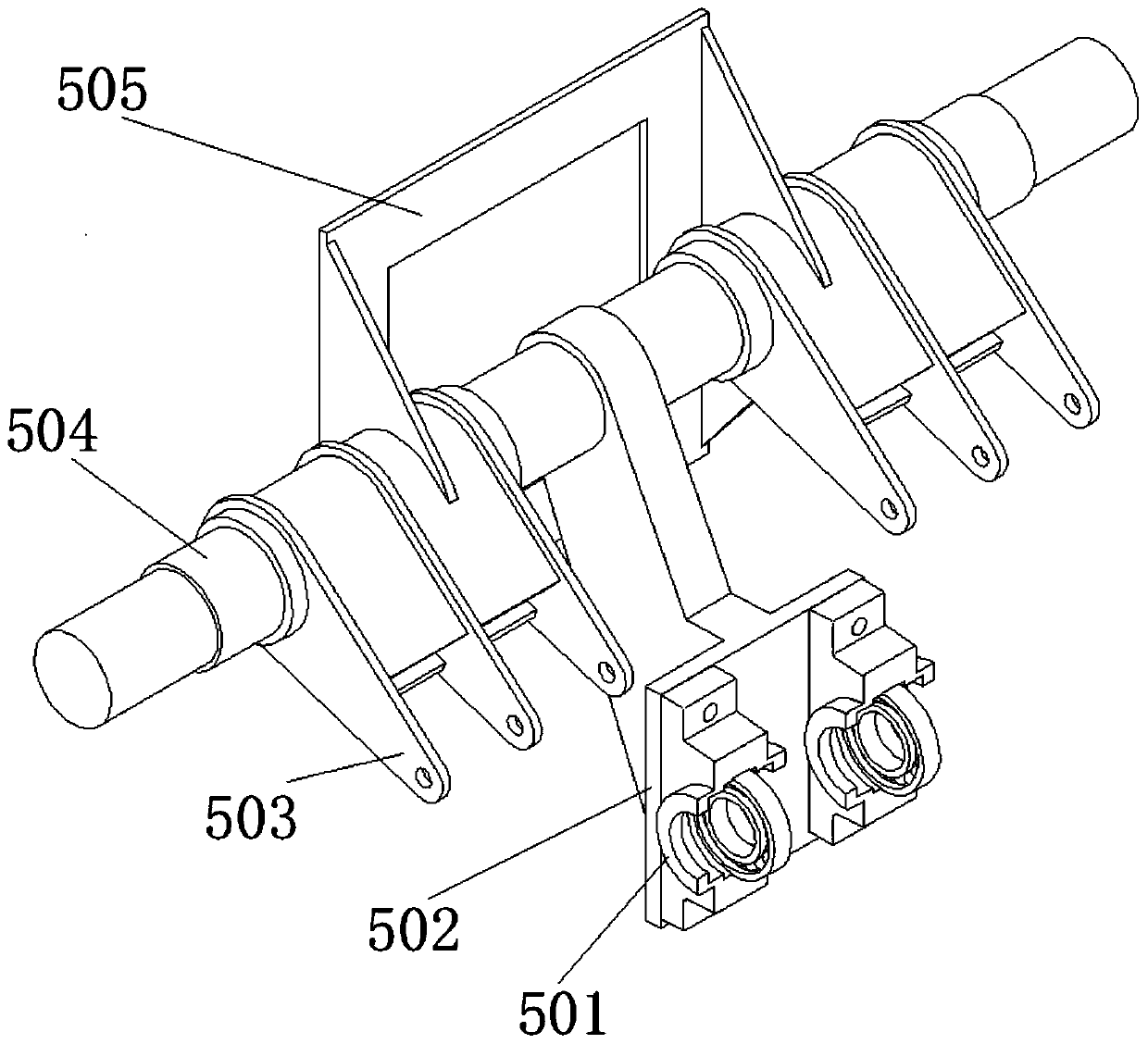

[0016] Such as Figure 1-2 As shown, a compound drive lifting device provided by the present invention includes a base 1, a mechanical drive device 2, a support base 3, a hydraulic cylinder 4, a rotating shaft 5, a bracket 6 and a lifting frame 7, and on the base 1 A mechanical drive device 2 , a support base 3 , a hydraulic cylinder 4 and a bracket 6 are installed, and a bearing seat on the support base 3 is assembled with a rotating shaft 5 for supporting and constraining the main shaft 504 . Such as figure 2 As shown, a rotating plate 501 and a mounting plate 505 are respectively provided in the middle of the rotating shaft 5, the rotating plate 501 is connected with the bearing seat 502 by bolts, the bearing seat 502 is connected with the mechanical driving device 2 for motion transmission, and the mounting plate 505 is connected with the lifting frame 7 is connected by bolts to drive the weight to complete the lifting movement. There is a bracket 6 under the lifting fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com