A method for regulating polyacrylonitrile-based carbon fiber and its surface groove structure

A polyacrylonitrile-based carbon fiber and groove technology, applied in the field of carbon fiber, can solve the problems of reducing the effective force-bearing area of the fiber, the large difference in the depth of the groove on the fiber surface, and reducing the strength, and achieves the depth and uniformity. The effect of controllable groove structure and reduction of solidification rate differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

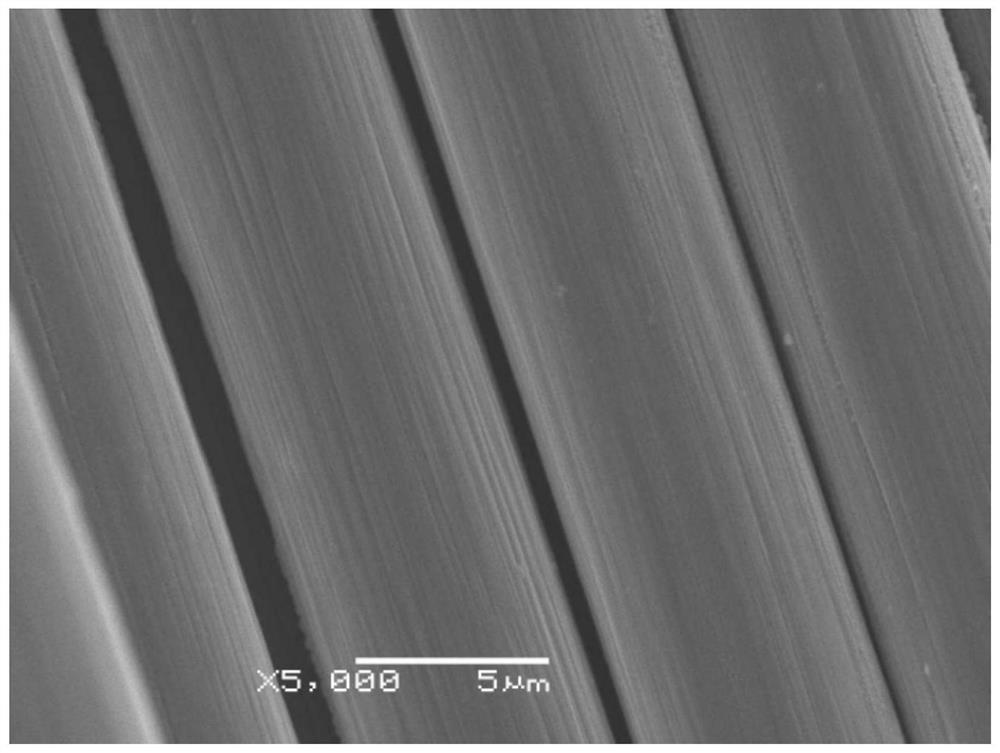

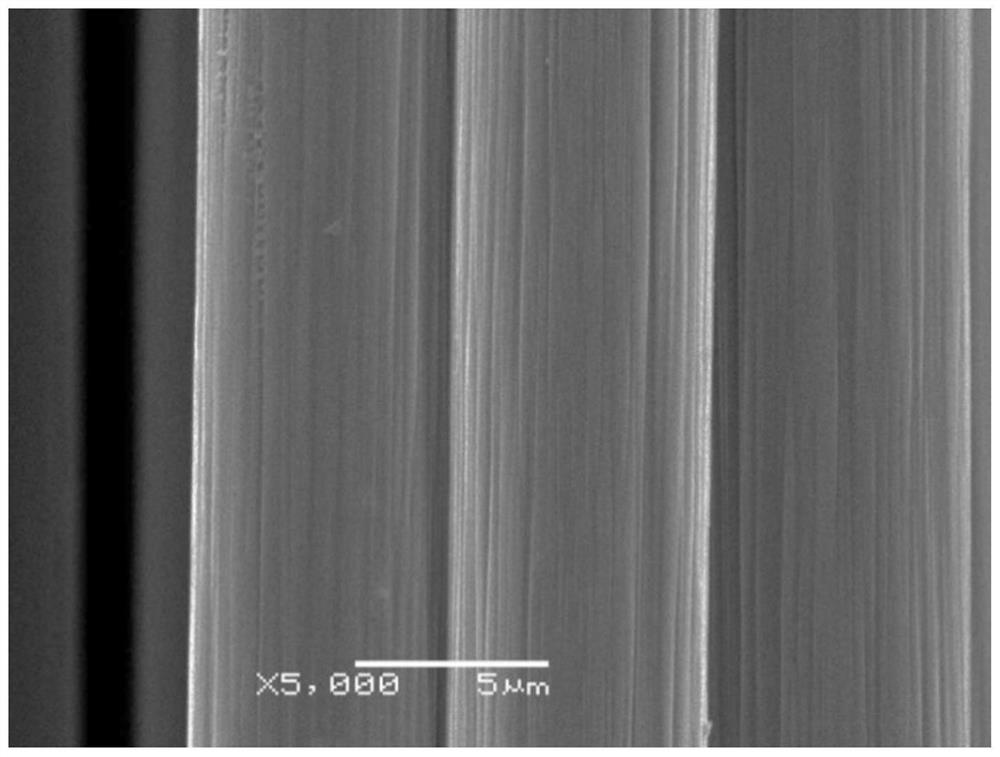

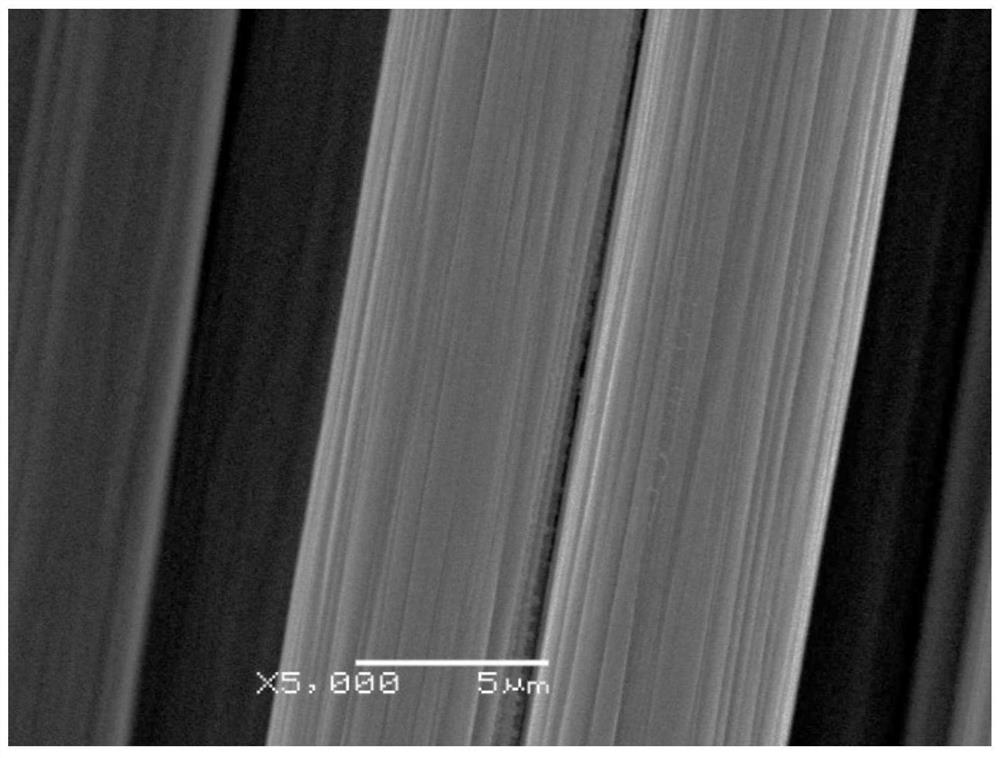

Image

Examples

Embodiment 1

[0093] 1) Preparation of spinning dope

[0094] Add the monomer acrylonitrile / itaconic acid / 2-acrylamido-2-methylpropanesulfonic acid into the reactor with stirring device according to the ratio of 97.8 / 1.00 / 1.2; the total monomer accounts for the mass percentage of the solution Is 25%. The amount of initiator azobisisobutyronitrile is 2% of the total weight of the monomer, and dimethylformamide is used as a solvent for solution polymerization. During the polymerization process, first bubbling high-purity nitrogen into the reactor for 15 minutes to replace the air in the reaction system, then start stirring and raise the temperature to 60°C, under the protection of nitrogen, constant temperature polymerization for 20 hours to obtain polyacrylonitrile spinning liquid.

[0095] 2) Solidification molding

[0096] Using wet spinning, the spinning solution is sprayed from the spinneret and then passes through an eight-stage coagulation bath to coagulate and form. Among them, the compo...

Embodiment 2

[0131] The difference from Example 1 is that the type of regulator in the coagulation bath is changed from ethanol to n-propanol.

Embodiment 3

[0133] The difference from Example 1 is that the type of regulator in the coagulation bath is changed from ethanol to ammonia.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com