Composite multilayer graphite flake structure and manufacturing method, heat dissipation structure and electronic device

A technology of graphite flakes and heat dissipation structure, which is applied in the direction of layered products, cooling/ventilation/heating transformation, modification through conduction and heat transfer, etc., which can solve the permanent damage of electronic components, affect the characteristics of electronic components, and the heat dissipation effect needs to be improved, etc. problem, to achieve the effect of improving heat dissipation, uniform heat conduction characteristics, and strong overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The composite multilayer graphite sheet structure and its manufacturing method, heat dissipation structure and electronic device with the heat dissipation device according to preferred embodiments of the present invention will be described below with reference to the relevant drawings, wherein the same elements will be described with the same reference symbols .

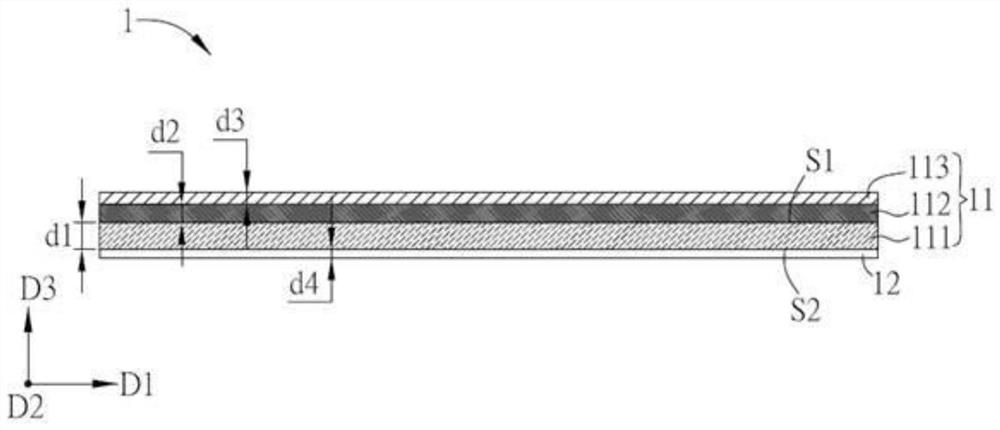

[0022] figure 1 It is a schematic diagram of a heat dissipation structure 1 according to an embodiment of the present invention. like figure 1 As shown, the heat dissipation structure 1 of this embodiment can be used in conjunction with a heat source, and the heat dissipation structure 1 can include a composite multilayer graphite sheet structure 11 and an adhesive layer 12 . Wherein, the composite multilayer graphite flake structure 11 includes a graphite material layer 111 , a ceramic material layer 112 and a radiation heat dissipation layer 113 .

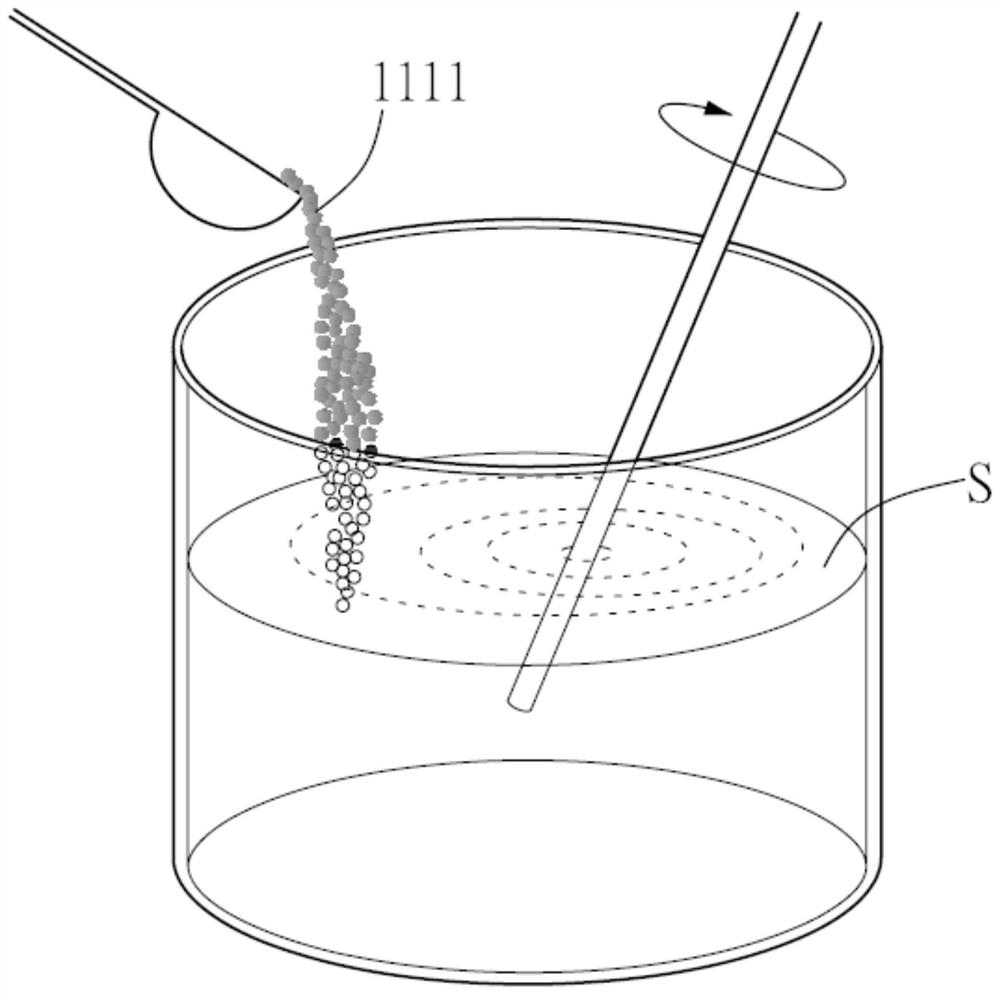

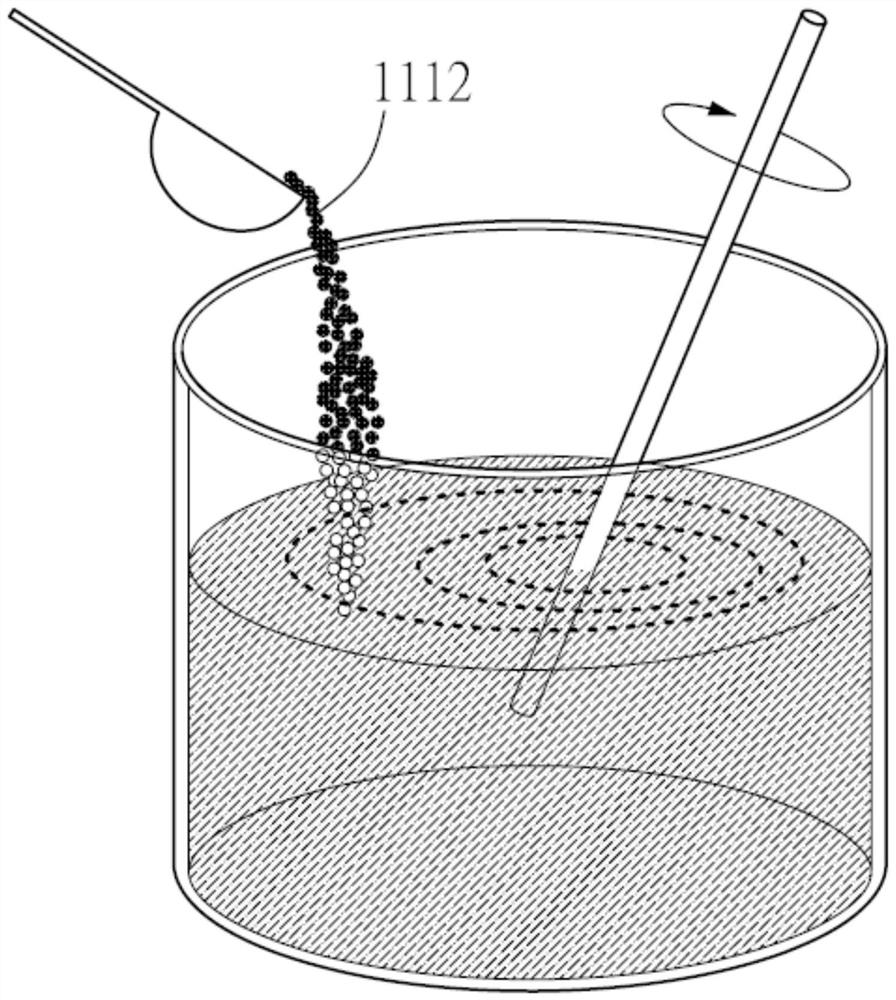

[0023] The graphite material layer 111 has a first surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com