A four-degree-of-freedom vertical installation platform

A technology of installation platform and degrees of freedom, applied in the direction of hoisting device, transportation and packaging, load hoisting components, etc., can solve the problems of time-consuming and labor-intensive satellite cabin and satellite body, collision or damage of parts, and long time consumption. Achieve the effect of wide range of attitude adjustment, strong load capacity and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Exemplary embodiments, features, and performance aspects of the present invention will be described in detail below with reference to the accompanying drawings. The same reference numbers in the figures indicate functionally identical or similar elements. While various aspects of the embodiments are shown in drawings, the drawings are not necessarily drawn to scale unless specifically indicated.

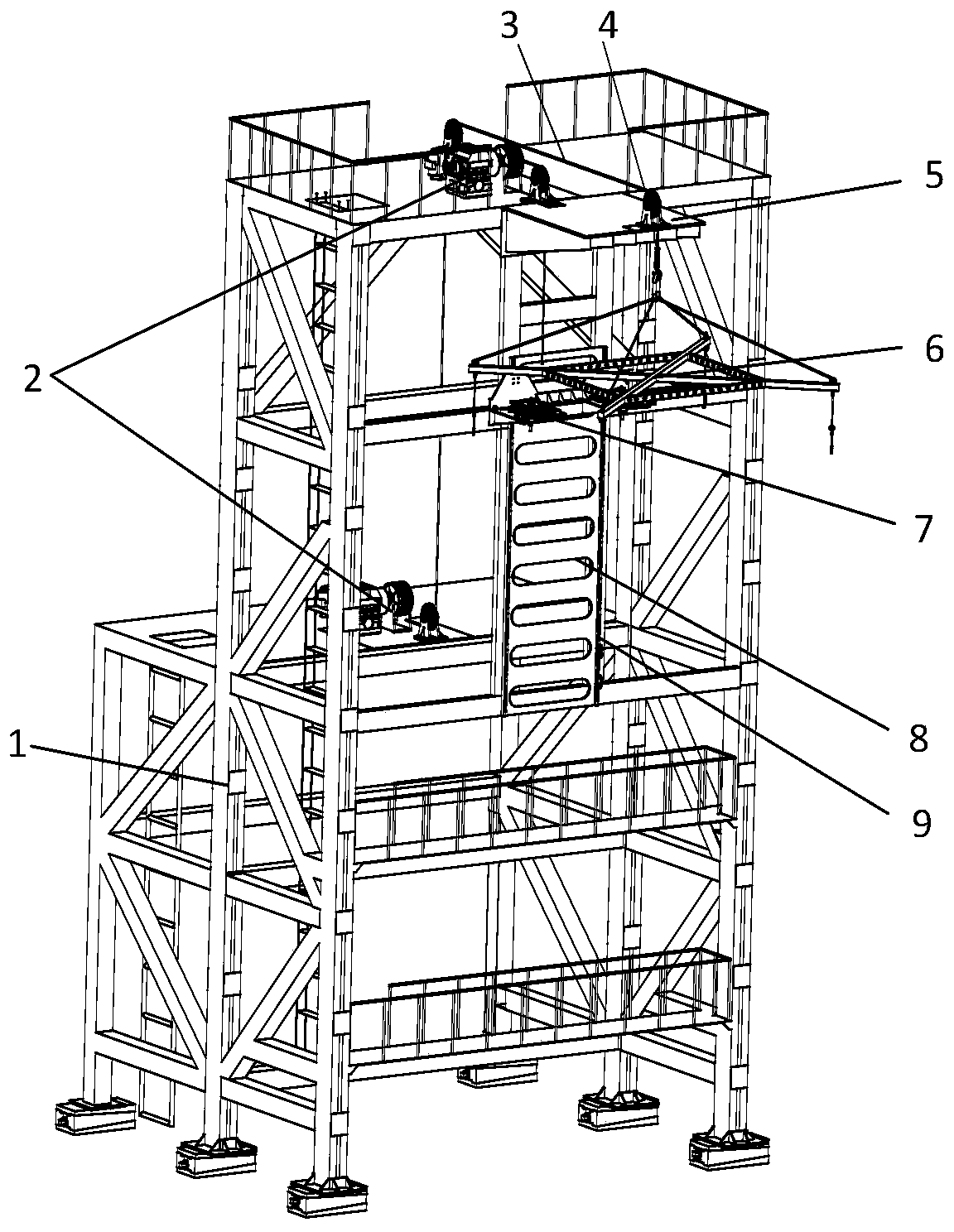

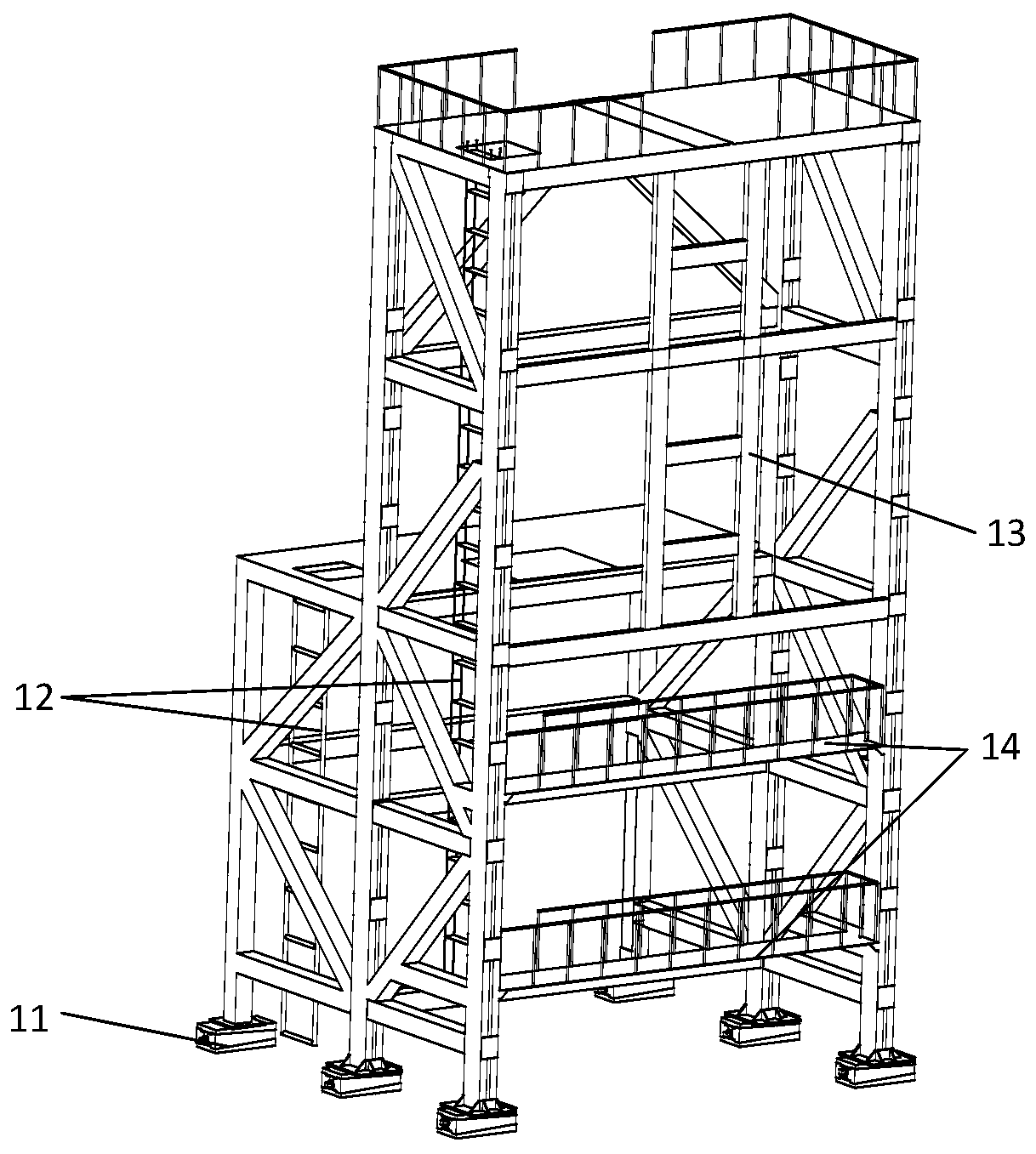

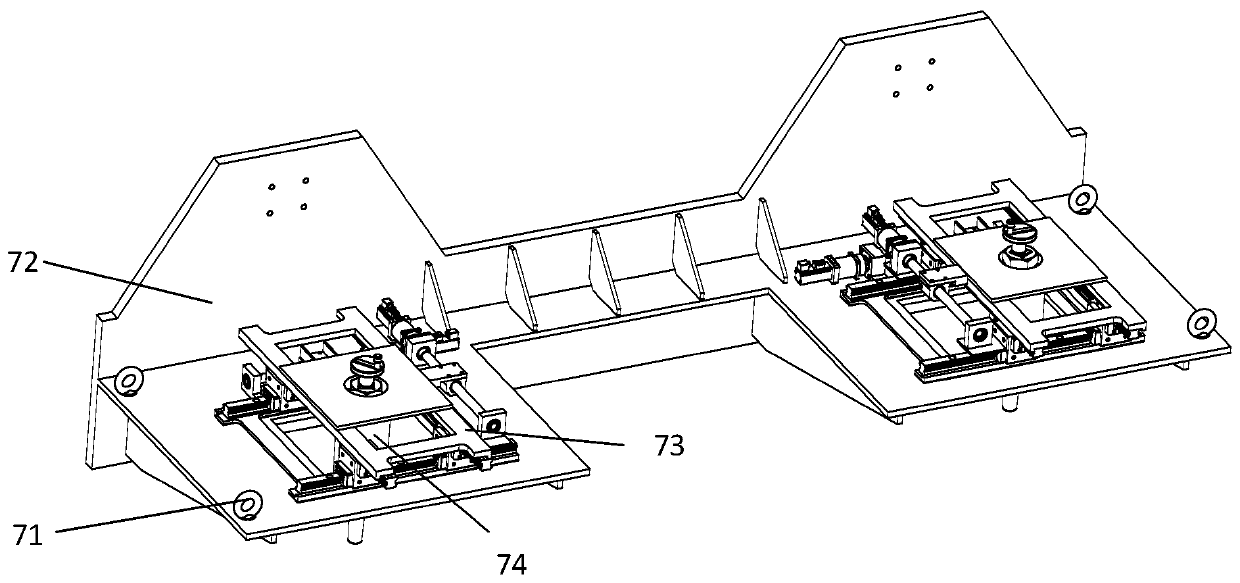

[0027] like Figure 1 to Figure 4 As shown, a four-degree-of-freedom vertical installation platform according to the present invention is configured for large-scale vertical assembly, specifically, it includes a support platform 1, a winch drive system 2, a spreader support plate 5, and a spreader 6 , a pose adjustment mechanism 7, a guide rail mounting plate 8 and a guide rail slider system 9. The winch drive system 2 is arranged on the support platform 1, the winch drive system 2 includes a first winch drive system and a second winch drive system, the first winch drive sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com