Engine compartment bracket assembly mounting structure and vehicle

A bracket assembly and installation structure technology, which is applied in the direction of superstructure, vehicle parts, superstructure sub-assembly, etc., can solve the problem that it is difficult to meet the high-level safety standards of pure electric vehicles, the rigidity and strength are not high, and the cabin bracket structure is not enough Stability and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The core of the present invention is to provide a nacelle bracket assembly installation structure and vehicle, which can not only meet the requirements of strength and rigidity, but also meet the requirements of vehicle stability, avoid forming resonance, and significantly improve the performance of the vehicle's NVH, safety level, etc. .

[0045] In order to enable those skilled in the art to better understand the technical solutions provided by the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

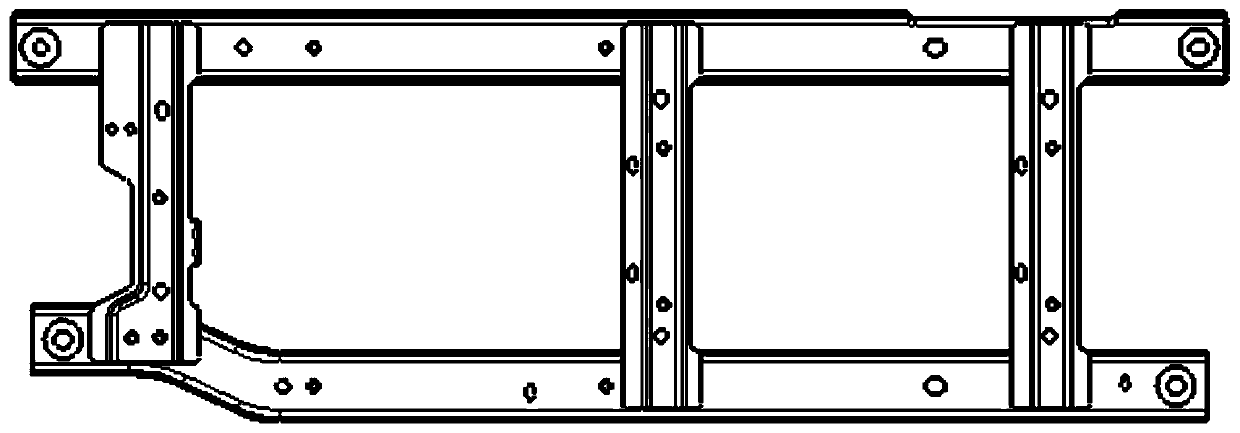

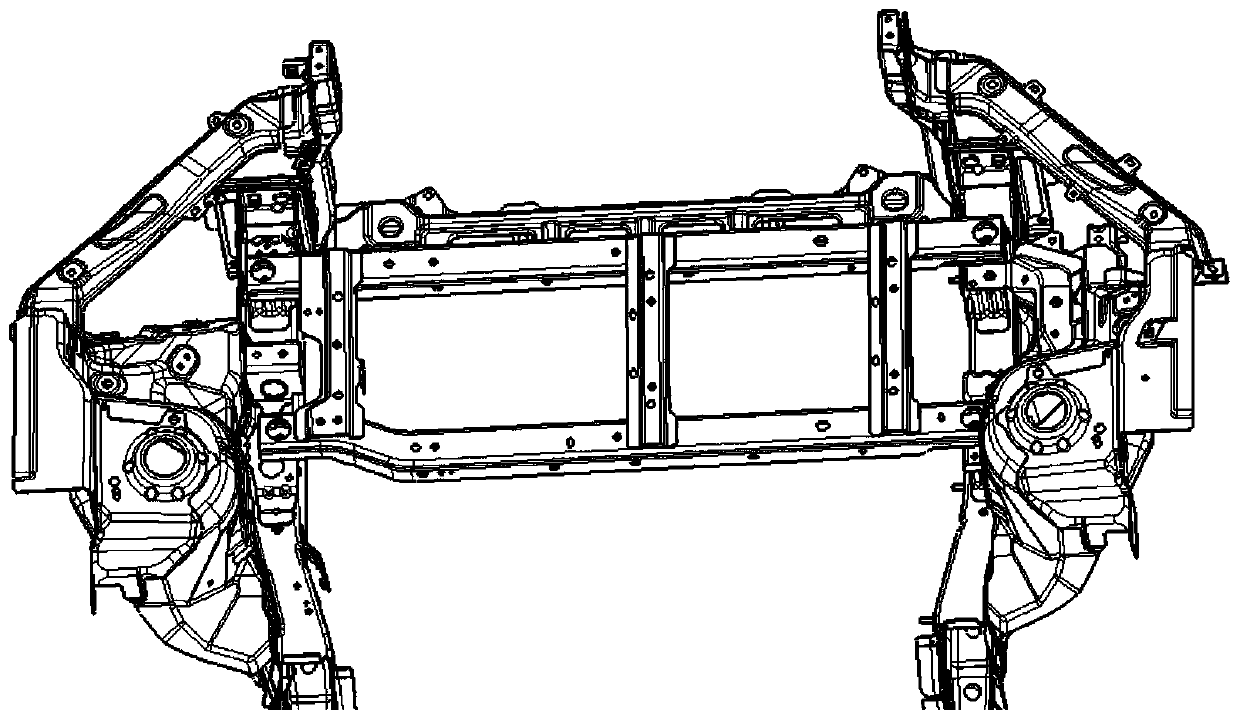

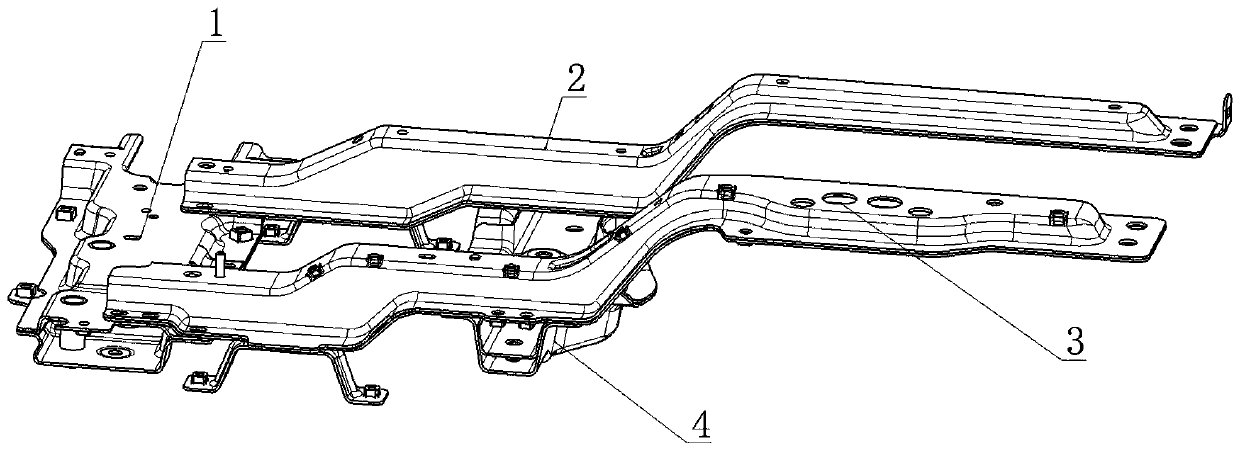

[0046] Please refer to Figure 3-Figure 18 , The present invention provides a nacelle bracket assembly installation structure, including nacelle bracket front cross beam assembly 2, nacelle cross beam assembly 3, left longitudinal beam reinforcement assembly 1, ground left suspension 28, motor mounting bracket 30 and right suspension 29. Among them, the engine room bracket fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com