Dynamic axle load instrument

An axle load meter and dynamic technology, applied in the field of axle load meter, can solve problems such as insufficient real-time performance, and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with embodiments.

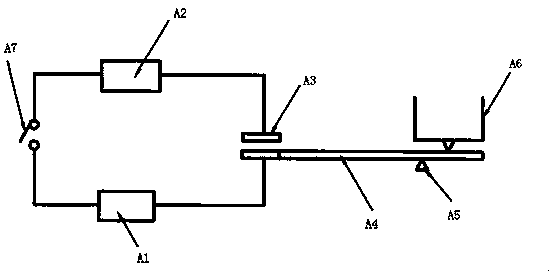

[0012] Such as figure 1 As shown, the dynamic axle load meter of this embodiment is equipped with a rotating bar A4 under the cab A6. The cab A6 is located in the first bar of the rotating bar A4, and the second bar of the rotating bar A4. A magnet is positioned on the body, and another magnet of the same polarity is arranged on the magnet, which is connected to a pair of magnets A3 of the same polarity via a chip composed of a battery A1 and a buzzer operating device A2.

[0013] When the axle is too heavy, cooperate with the rotating bar to suppress the contact of a pair of magnets of the same pole. The chip connected to the magnet is turned on, and the buzzer control device emits a buzzing sound to simultaneously isolate the activation chip in the axle, so that The axle cannot move.

[0014] The buzzer control device A2 is an existing control device.

[0015] The dynamic axle load mete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com