Intelligent substation equipment sampling check method and system based on continuity variance

A smart substation and continuity technology, applied in the direction of measuring electricity, measuring electrical variables, instruments, etc., can solve the problems of unguaranteed correctness, high degree of correlation, no judgment standards, etc., to improve correctness and standardization, improve The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

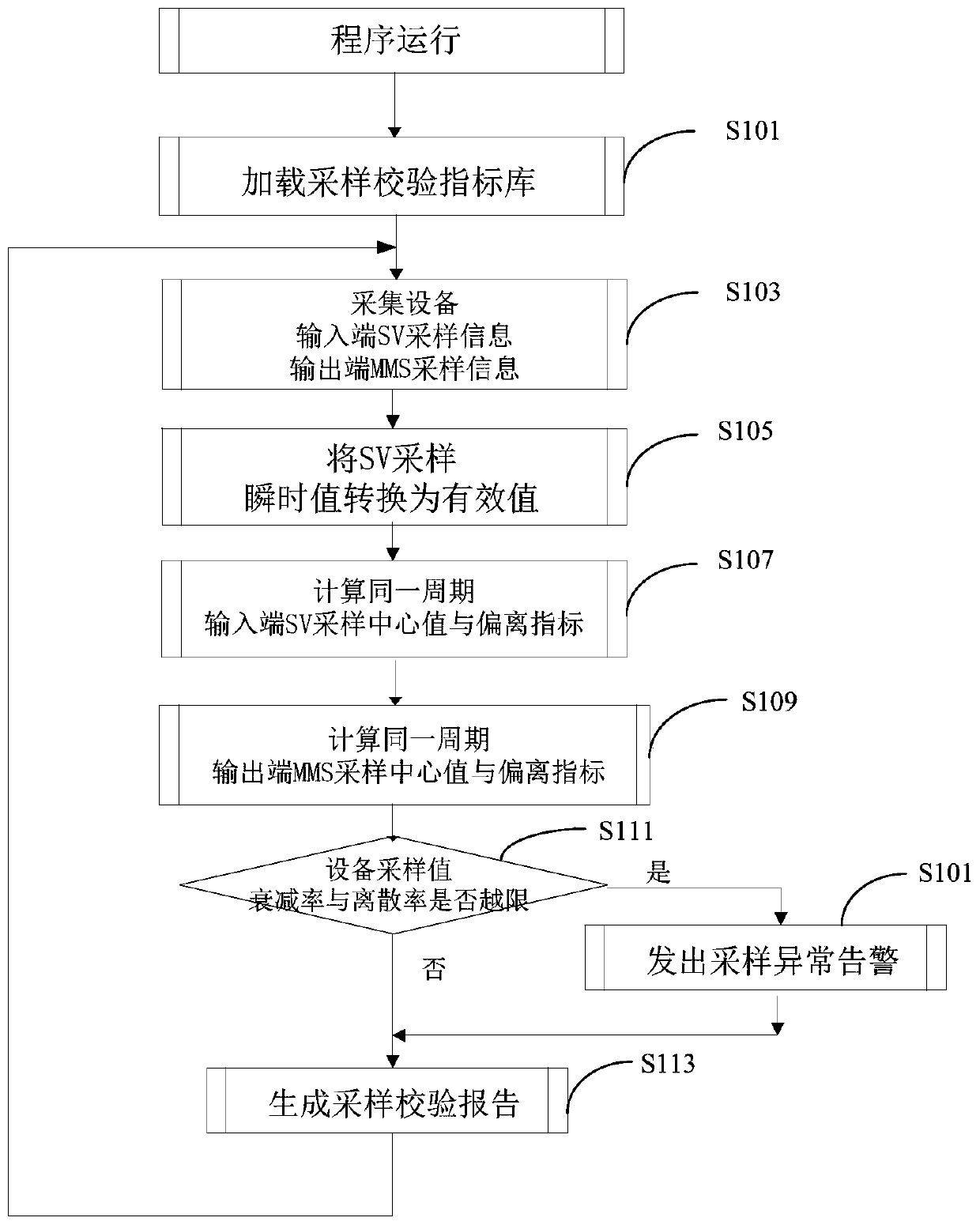

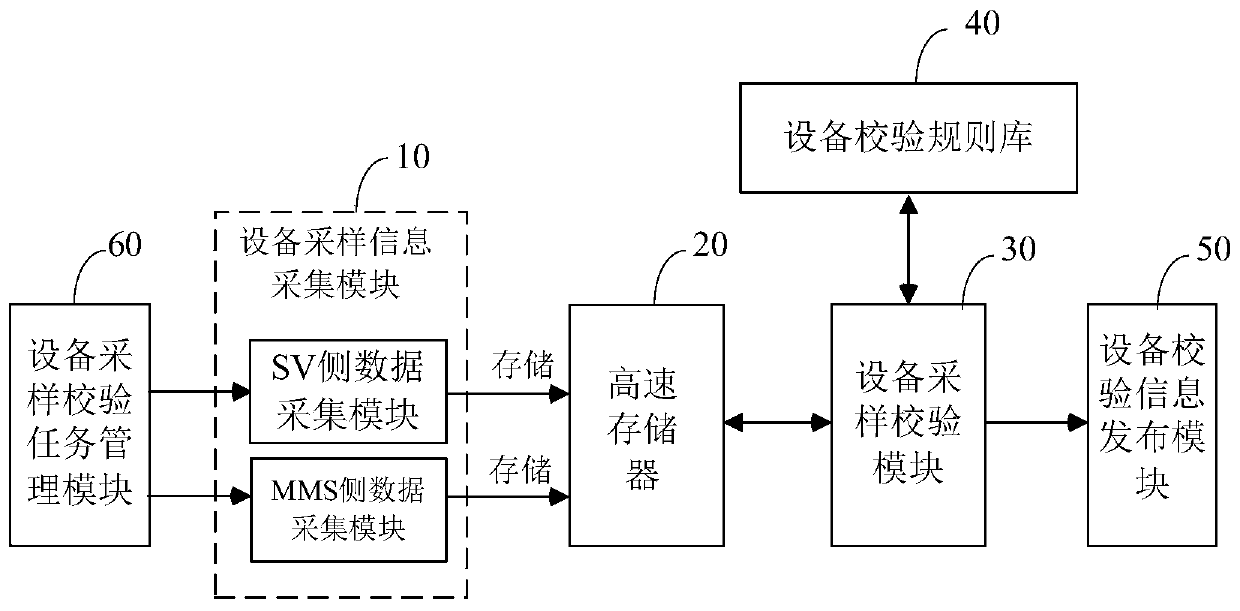

[0027] The present invention provides a method for sampling and verifying intelligent substation equipment based on continuity variance. On the one hand, it can replace the manual sampling and verifying method of generating sampling output information by increasing the amount of testing equipment on the equipment. On the other hand, it can be used when the equipment is not The verification of the sampling state of the equipment is completed under the state of power outage maintenance, and the whole test process can meet the sampling verification of different types and different voltage levels of the whole station.

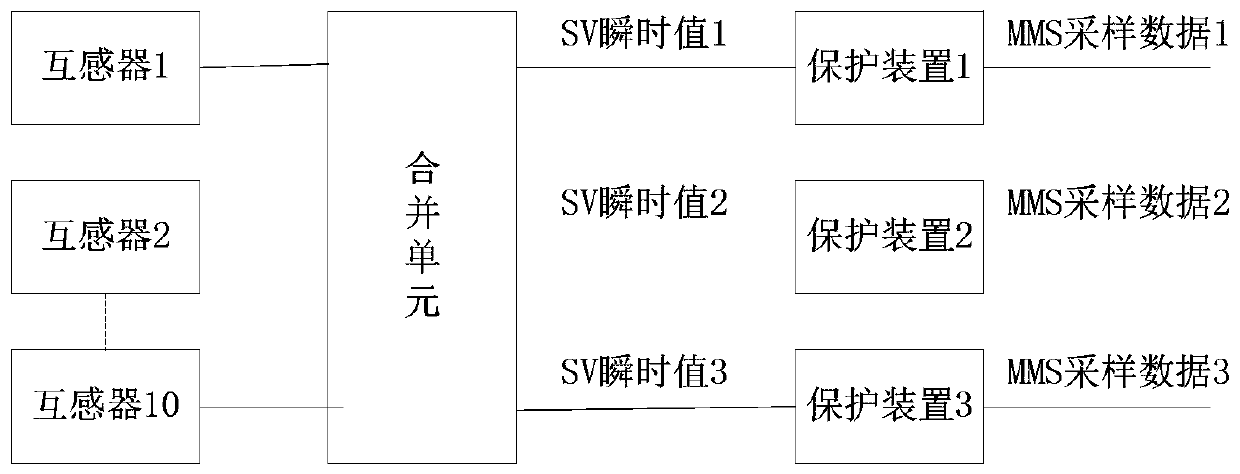

[0028] The intelligent substation equipment of the present invention includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com