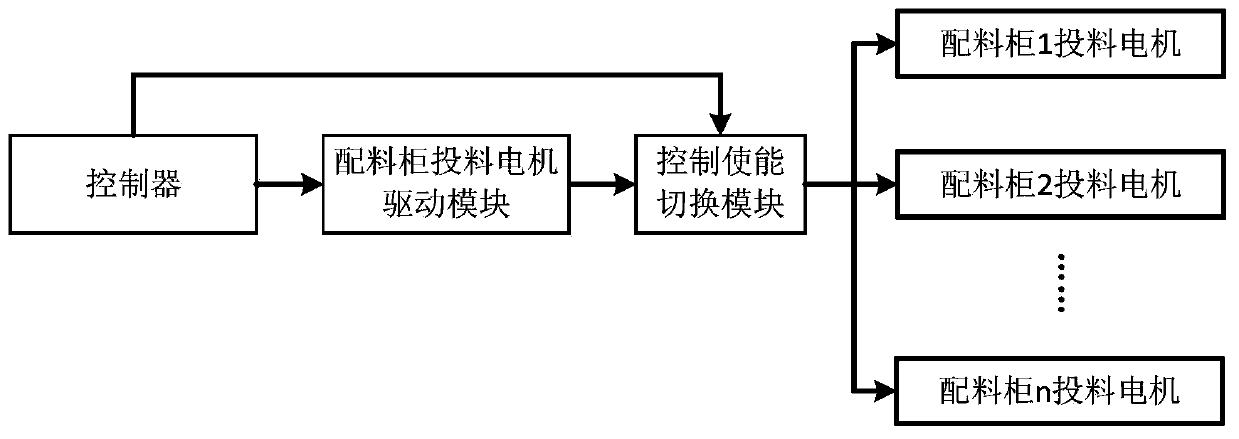

Centralized time sharing control system and method for automatic proportioning cabinets

A time-sharing control and automatic batching technology, which is applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of limited beverage blending varieties and high cost of electromechanical systems, and achieve optimal use quantity, simple and clear control loops, The effect of reducing the cost of electromechanical systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0052] There are three hoppers, the first hopper has 3 silos, the second hopper has 2 silos, and the third hopper has 2 silos, and the silos of the hoppers are loaded with concentrated juice in sequence 1 to 7. The number of bins in this group of bins is at most n max =3, then the ingredient number list is:

[0053] 3

4

5

Concentrated Juice1

Concentrated Juice 2

Concentrated Juice 3

6

7

8

Juice Concentrate4

null

Concentrated Juice 5

9

10

11

Concentrated Juice 6

null

Concentrated Juice7

[0054] Obtain the ingredient information, including the ingredient name concentrated fruit juice 4, and the dosage L, then the number of the ingredient is 6 by looking up the table

[0055] Divide the ingredient code 6 by 3 to get a quotient of 2 and a remainder of 0, then the ingredient is the first bin of the second bin, and the quotient is P s For the number of the material bin, switch the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com