High-efficiency sugarcane leaf stripping machine

A defoliator and sugarcane technology, applied in harvesters, agricultural machinery and implements, applications, etc., can solve the problem that sugarcane skin is easily damaged, difficult to automatically adapt to different diameters of cane stems, and affects sugarcane defoliation, cutting tips, seed retention and harvesting. and other problems, to achieve the effect of simple and effective switching method, uniform force and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

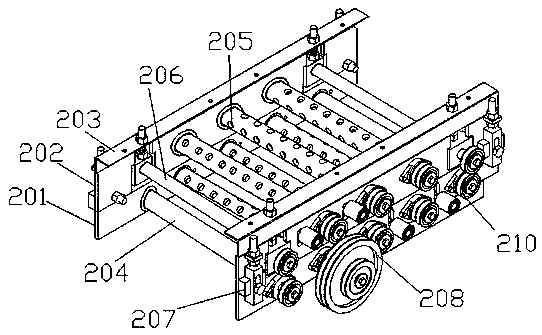

[0031] refer to Figure 1-6 , a high-efficiency sugarcane leaf stripper, mainly composed of a frame 1, a stripping mechanism 2 above the frame 1, a cutting mechanism 3 at the front end of the stripping mechanism 2, a feeding table 4 at the front end of the cutting mechanism 3, and a drawer at the front end of the feeding table 4 The frame 5 is composed of the engine 6 inside the frame 1, the clutch mechanism 7 and the speed reducer 8, and the traveling mechanism 9 erected on the frame 1.

[0032] refer to Figure 1-6 , stripping leaf mechanism 2 comprises fixed splint 201, movable splint 202, angle iron bar 203, fixed shaft 204 and leaf-stripping shaft 205 erected o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com