Device for jointly testing internal force and external force of shield tunnel duct piece and manufacturing and burying method

A shield tunnel segment and joint testing technology, which is applied to measuring devices, tunnels, tunnel linings, etc., can solve problems such as water seepage accidents, long burying time, and difficult operations, and achieve strict cable protection measures and shorten burying time , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

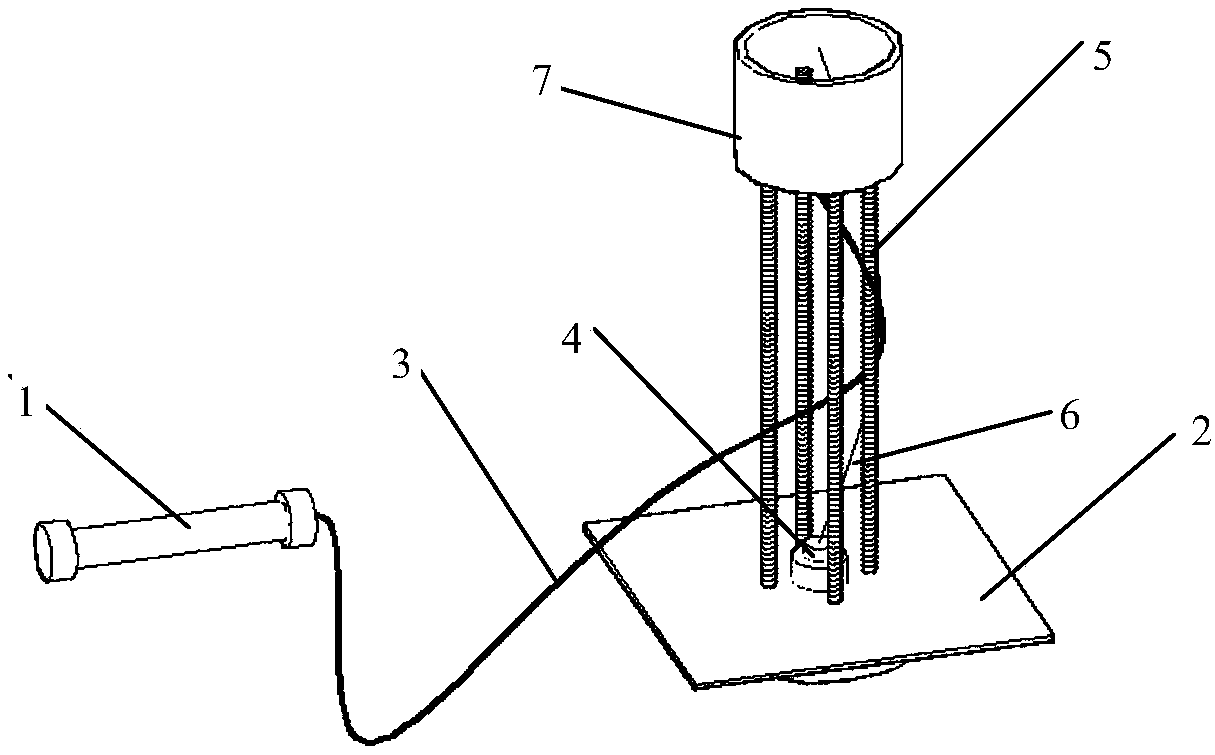

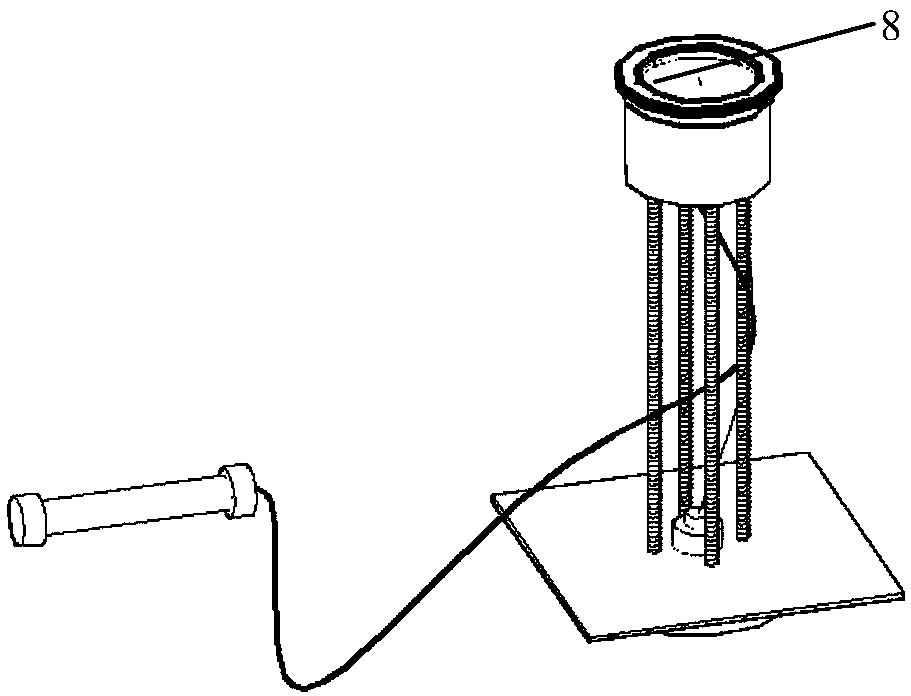

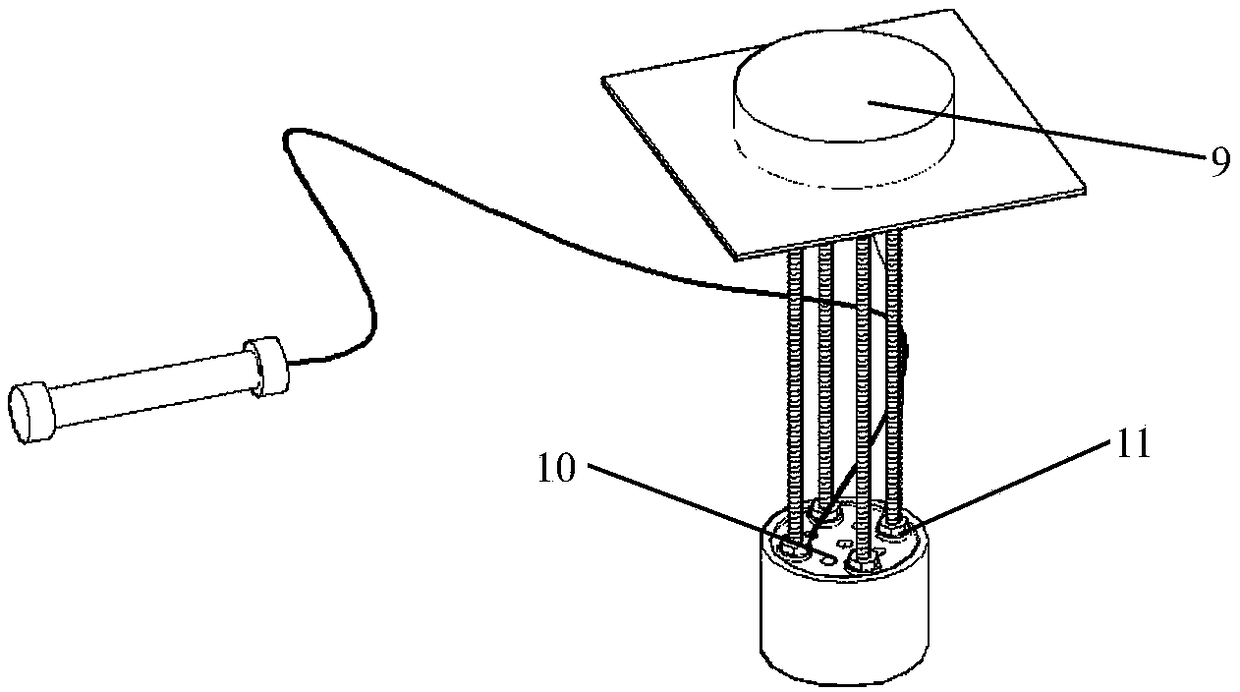

Embodiment 1

[0068] A combined test device for internal and external forces of a shield tunnel segment is mainly composed of a steel bar strain gauge, an earth pressure sensor, a water-stop steel plate, a cable protection box and a connecting screw. One end of the steel bar strain gauge 1 is connected to the steel bar strain gauge The cable 3 is connected to the steel cage 17 of the shield segment through the lead wire binding method. The steel bar strain gauge cable 3 passes through the cable protection box 7, and the cable protection box 7 is connected to the stopper through the connecting screw 5. The water steel plates 2 are connected, and an adjusting nut 11 and a gasket 16 are arranged between the connecting screw rod 5 and the cable protection box 7. The bottom surface of the cable protection box 7 is provided with a corresponding number of threading holes 10, and the top surface is provided with There is a cable protection box cover 8 and a protective sponge 20 at the bottom of the ...

Embodiment 2

[0081] The manufacturing and embedding method of the joint measurement device for the internal force of the shield tunnel segment and the external earth pressure of the segment is as follows:

[0082] (1) Prepare a steel plate in advance, cut the steel plate into a square, and drill a hole in the center of the steel plate to make a water-stop steel plate 2 . Prepare a cover cable protection box 7 with a diameter of about 9 cm and a height of about 7 cm, drill four threading holes 10 with a diameter of 6 mm around the bottom of the steel bar strain gauge cable 3 protection box, and drill several holes with a diameter of 8 mm evenly distributed on other parts of the bottom surface. Small holes, the number of 8mm small holes is equal to the sum of the numbers of the earth pressure sensor 9 and the steel bar strain gauge 1 . Utilize the connecting screw 5 with a diameter of 6 mm to cut the screw into several small sections, the length of each section is the thickness of the segmen...

Embodiment 3

[0086] The test site is located in the section between Gaotangqiao Station and Jiangshan Station of Ningbo Rail Transit Line 3. The connecting passage in this section is constructed by mechanical method, that is, small shield construction is used. The small shield construction is provided by the main tunnel shield segment. Therefore, it is necessary to grasp the internal force and external earth pressure of the shield segment of the main tunnel in time during the construction of the small shield. The surrounding stratum conditions and sensor embedding conditions of the communication channel construction are as follows: Figure 15 , 16 shown.

[0087] After the tunnel shield segment is buried, the earth pressure outside the segment and the internal force of the segment are tested. The test results are as follows: Figure 17 As shown, the unit of earth pressure is kPa, and the unit of segment bending moment is kN·m. It can be seen from the test results that the present invent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com