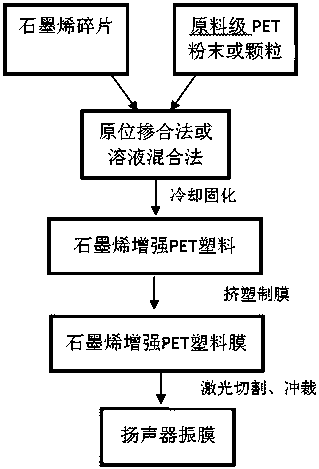

Loudspeaker acoustic diaphragm based on graphene reinforced PET plastics, and preparation method thereof

A graphene and loudspeaker technology, applied in the direction of loudspeakers, sensors, electrical components, etc., can solve the problems of poor firmness, low strength, and foaming of the diaphragm, and achieve the effect of light weight and small thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Preferred embodiment one is made by in-situ blending method, and the specific operations include the following steps:

[0028] 4A. Swell the graphene or its compound fragments at a temperature ranging from 150°C to 250°C for 2 to 5 minutes, and then disperse the graphene and / or its compound fragments in a polar solvent at room temperature by ultrasonic vibration , making a suspension of graphene and / or its compound fragments mixed with a polar solvent;

[0029] 4B. Inject the suspension of graphene and / or its compound fragments mixed with a polar solvent obtained in the previous step 4A into the powdery or granular polymer PET, and stir rapidly with the help of a mechanical device to form a slurry , and by esterification, obtain the PET macromolecular polymer slurry mixed with graphene and / or its compound fragments, in this slurry, graphene and / or its compound fragments cooperate with macromolecular polymer PET, by weight percentage , graphene and / or its compound fragm...

Embodiment 2

[0032]Preferred embodiment two, is to adopt the solution mixing method to make, and concrete operation comprises the following steps:

[0033] 6A. Disperse graphene and / or its compound fragments in ethanol solvent by ultrasonic vibration method at room temperature to make graphene and / or its compound fragments mixed with ethanol solvent suspension liquid;

[0034] 6B. Disperse the powdery or granular high molecular polymer PET in toluene solvent by ultrasonic vibration method to make PET polymer-toluene solvent mixed solution;

[0035] 6C. Under the condition of rapid mechanical stirring, the suspension of graphene and / or its compound fragments mixed with ethanol solvent obtained from the implementation of the above step 6A is injected into the PET polymer obtained from the implementation of the above step 6B-toluene solvent mixing In the solution, graphene and / or its compound fragments are fully and uniformly dispersed in the PET polymer-toluene solvent mixed solution, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com