An artificial floor for preventing bottom heaving of soft rock roadway and its construction and maintenance method

A floor and roadway technology, which is applied to the field of artificial floor and its construction and maintenance to prevent floor drums in soft rock roadways. It can solve the problems of inconvenient maintenance of floor drums, complex support structures, and floor erosion, and achieve water erosion and seepage prevention. The water effect is good and the effect of reducing the degree of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with drawings and embodiments.

[0052] This embodiment is an artificial floor laid in a soft rock roadway with a mine floor width of 4200 mm.

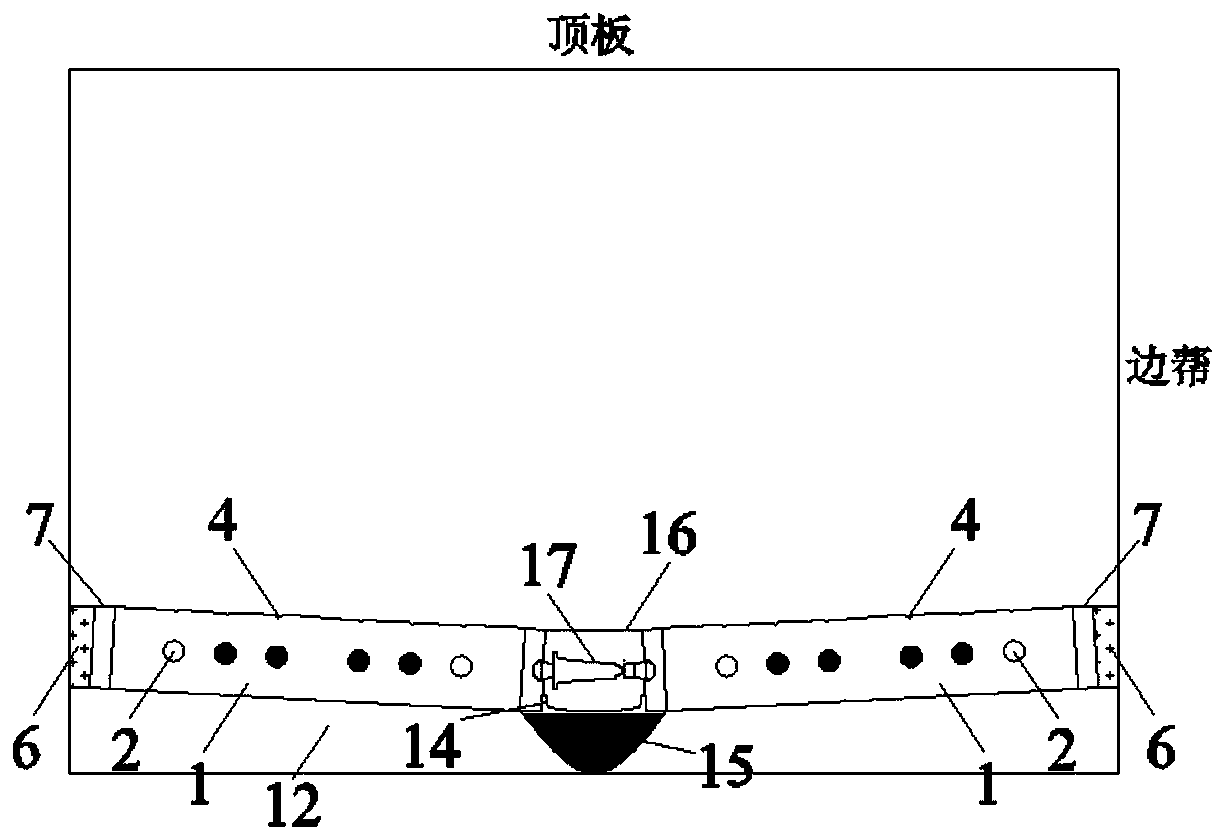

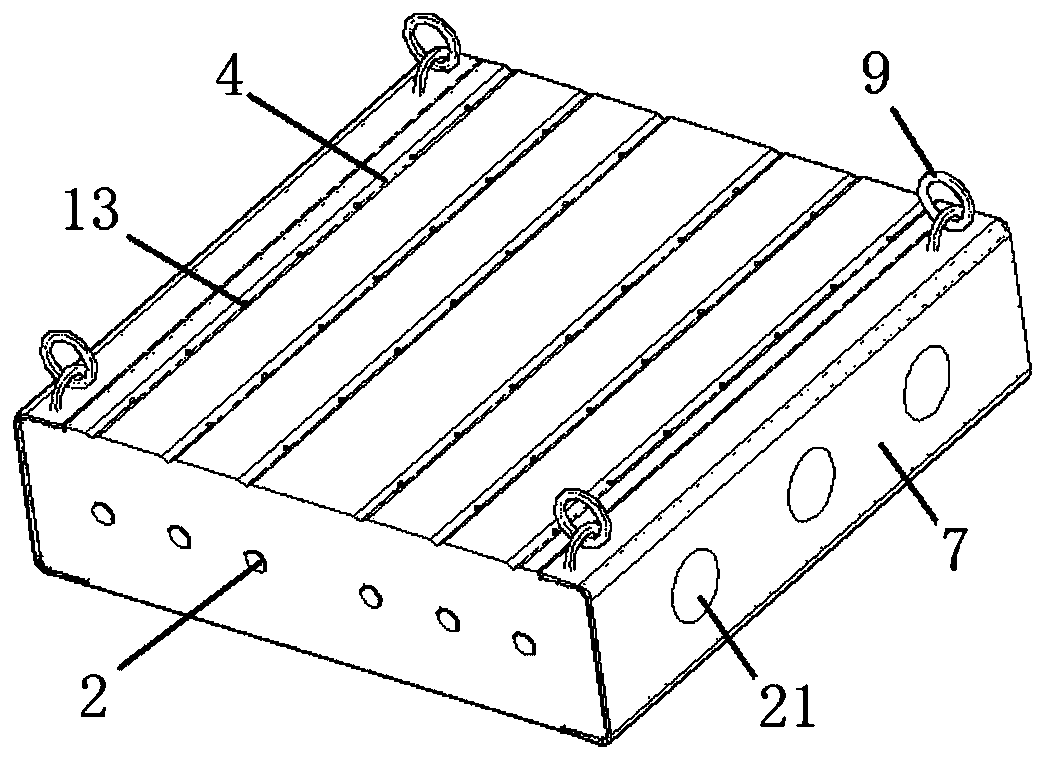

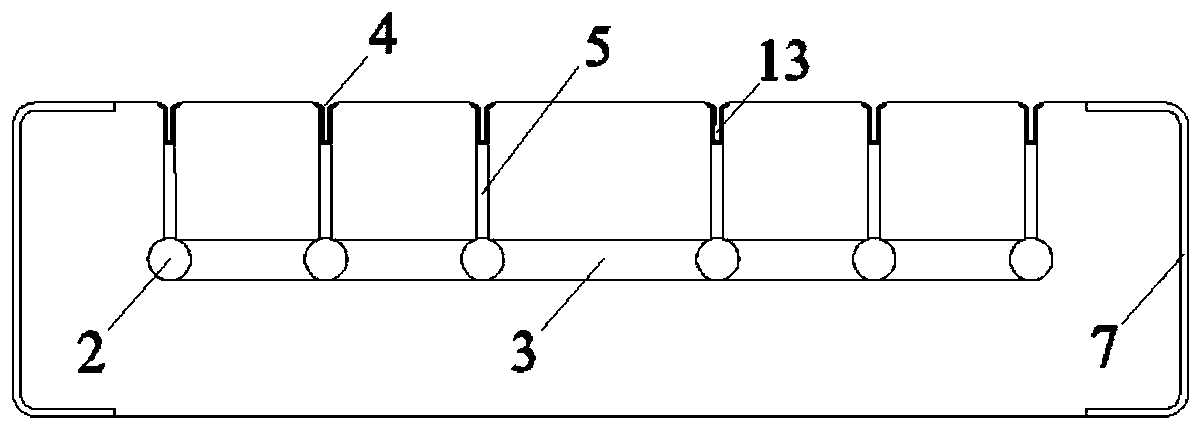

[0053] Such as figure 1 As shown, the artificial floor is formed by splicing square floor modules 1 laid on the roadway floor 12 .

[0054] Such as figure 2 and image 3 As shown, the floor module is composed of a reinforced concrete block with inter-connected vertical drainage pipes 2, horizontal drainage pipes 3 and vertical drainage pipes 5, wherein the upper end of the vertical drainage pipes is laid on the upper surface V of the floor module. The metal filter screen 13 in the shaped water tank 4 is connected; there are guard plates 7 made of channel steel on both lateral sides of the bottom plate module, and there are lifting rings 9 on the guard plate, and there is a hydraulic jack on the outer surface of one side of the guard plate. The hemispheric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com