Coal gangue concrete as well as preparation method and application thereof

A technology for coal gangue concrete and coal gangue, which is applied to clay preparation devices, chemical instruments and methods, sustainable waste treatment, etc., can solve the problems of time-consuming, energy-consuming, secondary pollution, etc., and achieves improved workability and cost savings. , the effect of enhancing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

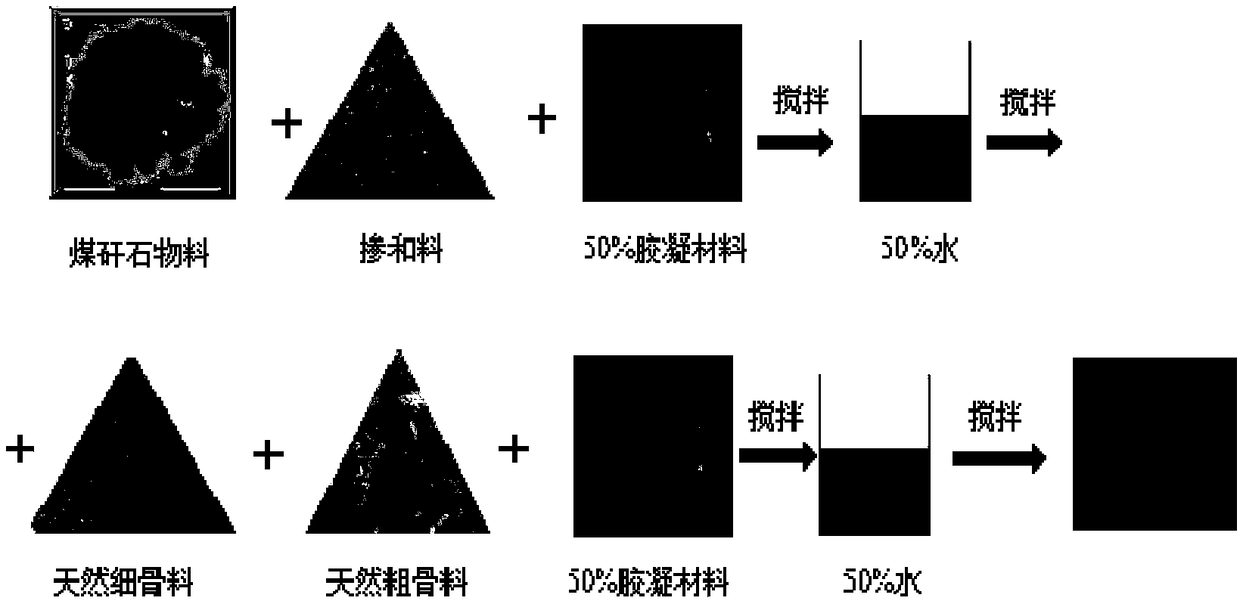

Method used

Image

Examples

Embodiment 1

[0036] A coal gangue concrete, the components include coal gangue raw materials and concrete materials; wherein, the coal gangue raw materials include components: coal gangue aggregates and admixtures, the concrete materials include cementitious materials, mixing water , natural coarse aggregate and natural fine aggregate, the volume percentage of each component is v1: v2: v3: v4: v5: v6 = 22%: 2%: 14%: 18%: 22%: 22%; where: Said v1 is the volume of coal gangue aggregate, v2 is the volume of admixture, v3 is the volume of cementitious material, v4 is the volume of stirring water, v5 is the volume of natural coarse aggregate, and v6 is the volume of natural fine aggregate;

[0037] The particle size of the gangue aggregate is 0.075-60 mm;

[0038] The cementitious material is cement;

[0039] The natural coarse aggregate is crushed stone or pebble, and the material is andesite or monzonite, etc.;

[0040] The natural fine aggregate is river sand or machine-made sand;

[0041...

Embodiment 2

[0053] A coal gangue concrete, the components include coal gangue raw materials and concrete materials; wherein, the coal gangue raw materials include components: coal gangue aggregates and admixtures, the concrete materials include cementitious materials, mixing water , natural coarse aggregate and natural fine aggregate, the volume percentage of each component is v1:v2:v3:v4:v5:v6=25%:2%:11%:12%:25%:25%; Said v1 is the volume of coal gangue aggregate, v2 is the volume of admixture, v3 is the volume of cementitious material, v4 is the volume of stirring water, v5 is the volume of natural coarse aggregate, and v6 is the volume of natural fine aggregate;

[0054] The particle size of the gangue aggregate is 0.075-60 mm;

[0055] The cementitious material is cement;

[0056] The natural coarse aggregate is crushed stone or pebble, and the material is andesite or monzonite, etc.;

[0057] The natural fine aggregate is river sand or machine-made sand;

[0058] The concrete mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com