Auxiliary device for assembly and disassembly of CV cylinder hoisting rope

An auxiliary device and cylinder technology, which is applied to workpiece clamping devices, manufacturing tools, etc., can solve the problems of low construction efficiency and poor safety, and achieve the effects of improving efficiency, improving efficiency and safety, and improving convenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

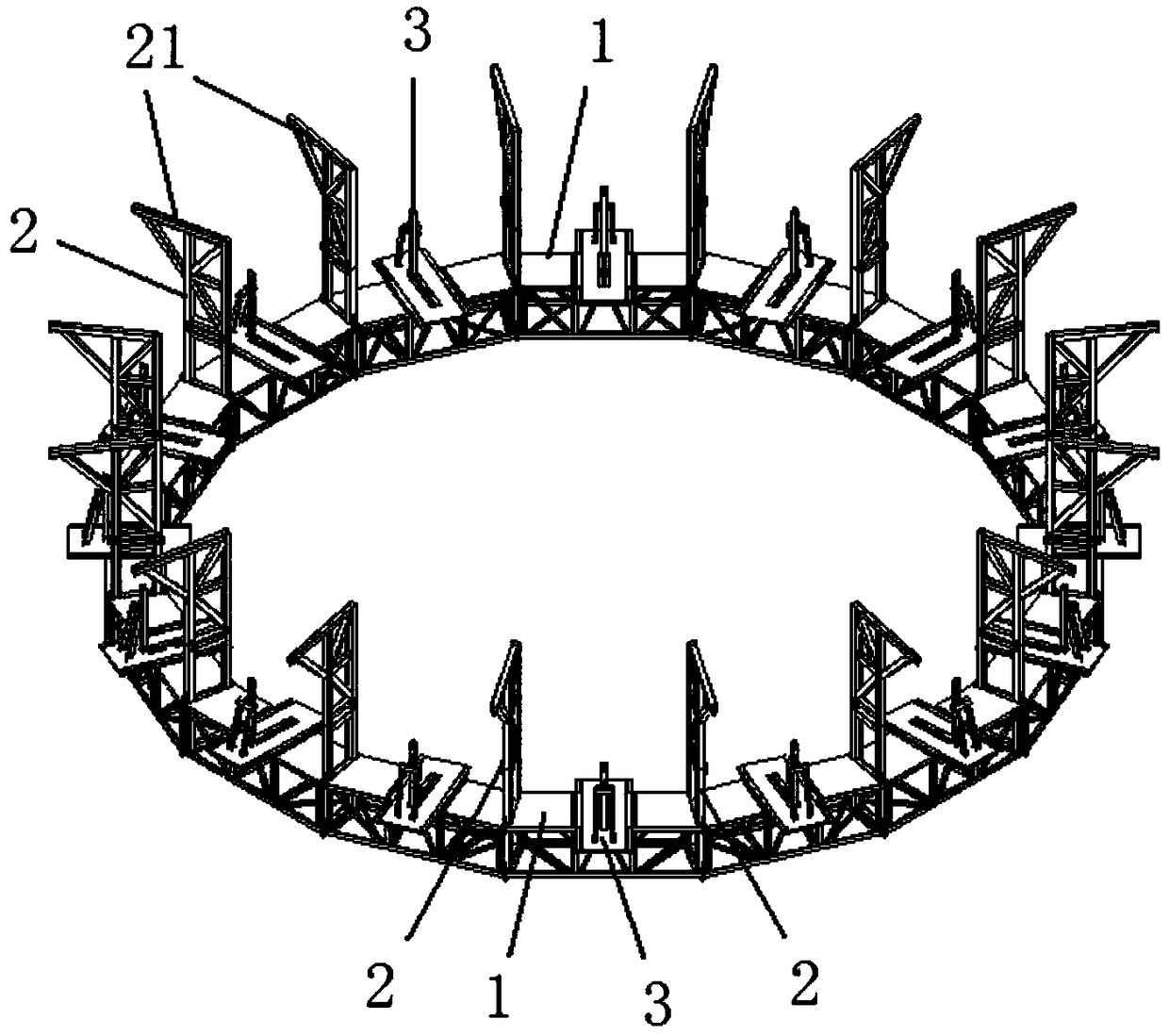

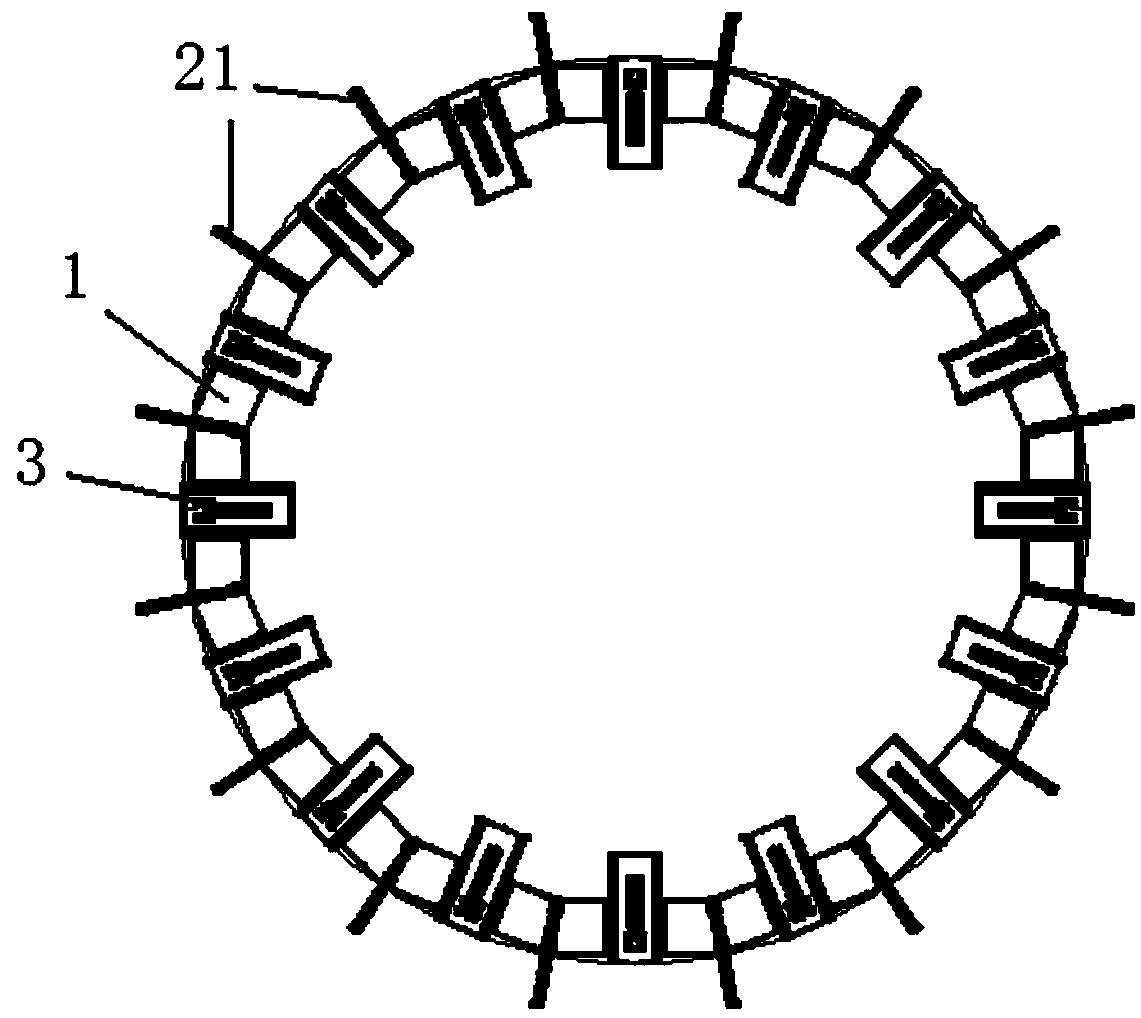

[0030] Embodiment 1 Suspended CV cylinder hoisting rope assembly and disassembly auxiliary device

[0031] combine figure 1 and figure 2 As shown, the CV cylinder hoisting rope assembly and disassembly auxiliary device of this embodiment includes a support platform 1 , a plurality of mounting frames 2 and a plurality of connecting frames 3 using a suspension frame structure. Wherein, the support platform 1 is a ring-shaped platform structure, and its outer diameter is slightly smaller than the inner diameter of the CV cylinder, so that it can be freely hoisted into and out of the cylinder along the vertical direction. A plurality of installation frames 2 are arranged along the circumferential direction of the support platform 1, and the lower end of each installation frame 2 is fixedly connected with the support platform 1 as a connection end, and the upper end is used as a suspension end to extend upwards in the vertical direction. The top of the upper end is provided with...

Embodiment 2

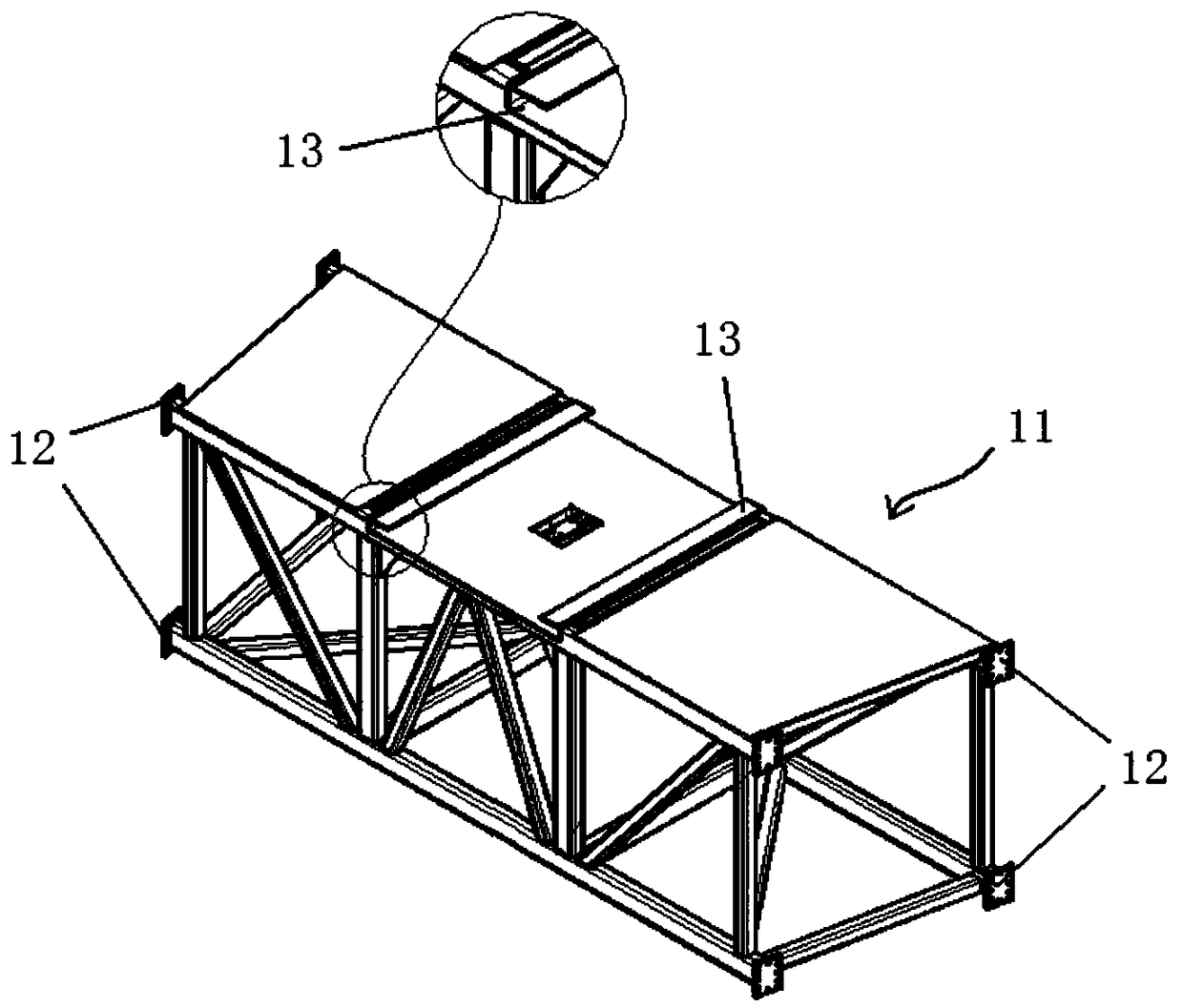

[0053] Embodiment 2 Auxiliary device for installation and disassembly of support type CV cylinder hoisting rope

[0054] combine Figure 10 As shown, the CV cylinder hoisting rope assembly and disassembly auxiliary device of the present invention can also adopt a supporting structure. Compared with the structure of the CV cylinder hoisting rope assembly and disassembly auxiliary device in the first embodiment, the only difference is that the mounting frame 2' in the second embodiment adopts a support frame structure arranged in a horizontal direction. At this time, the support frame as the installation frame 2' adopts a hollow frame structure, one end is connected to the support platform 11, and the other end protrudes in the horizontal direction and is supported and fixed on the inner lug of the CV cylinder. In this way, the crossbeam at the front end of the support frame can be used to build and connect with the lifting lug inside the CV cylinder, and at the same time, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com